Magnetball distributing plate for fluidized bed

A magnetic ball and distribution plate technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as the inability of gas to be evenly distributed, and achieve the effect of easy production, simple principle, and uneven distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

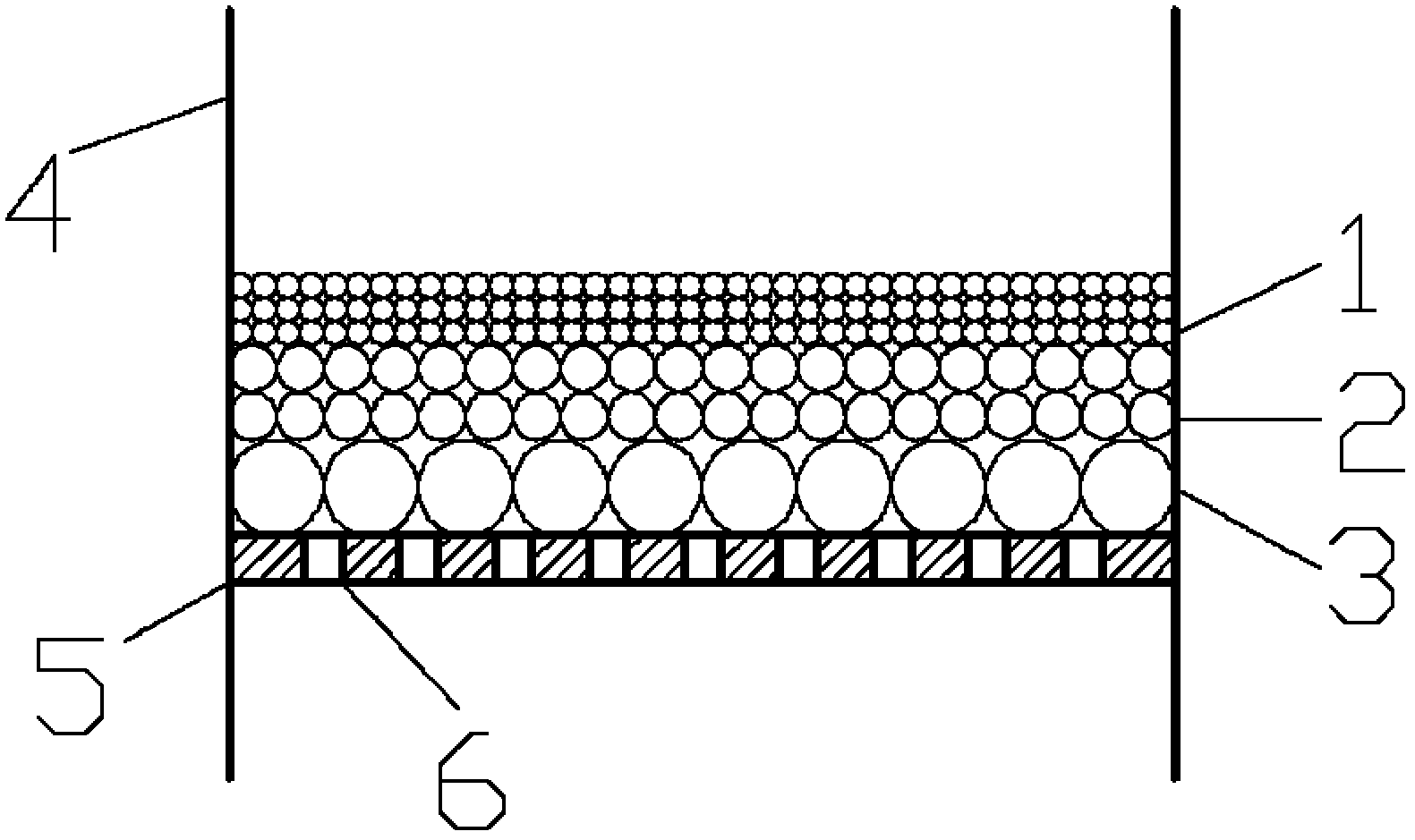

[0029] One of the specific examples of the present invention model example 1, as attached figure 1 As shown, all components and reactors are numbered, in order:

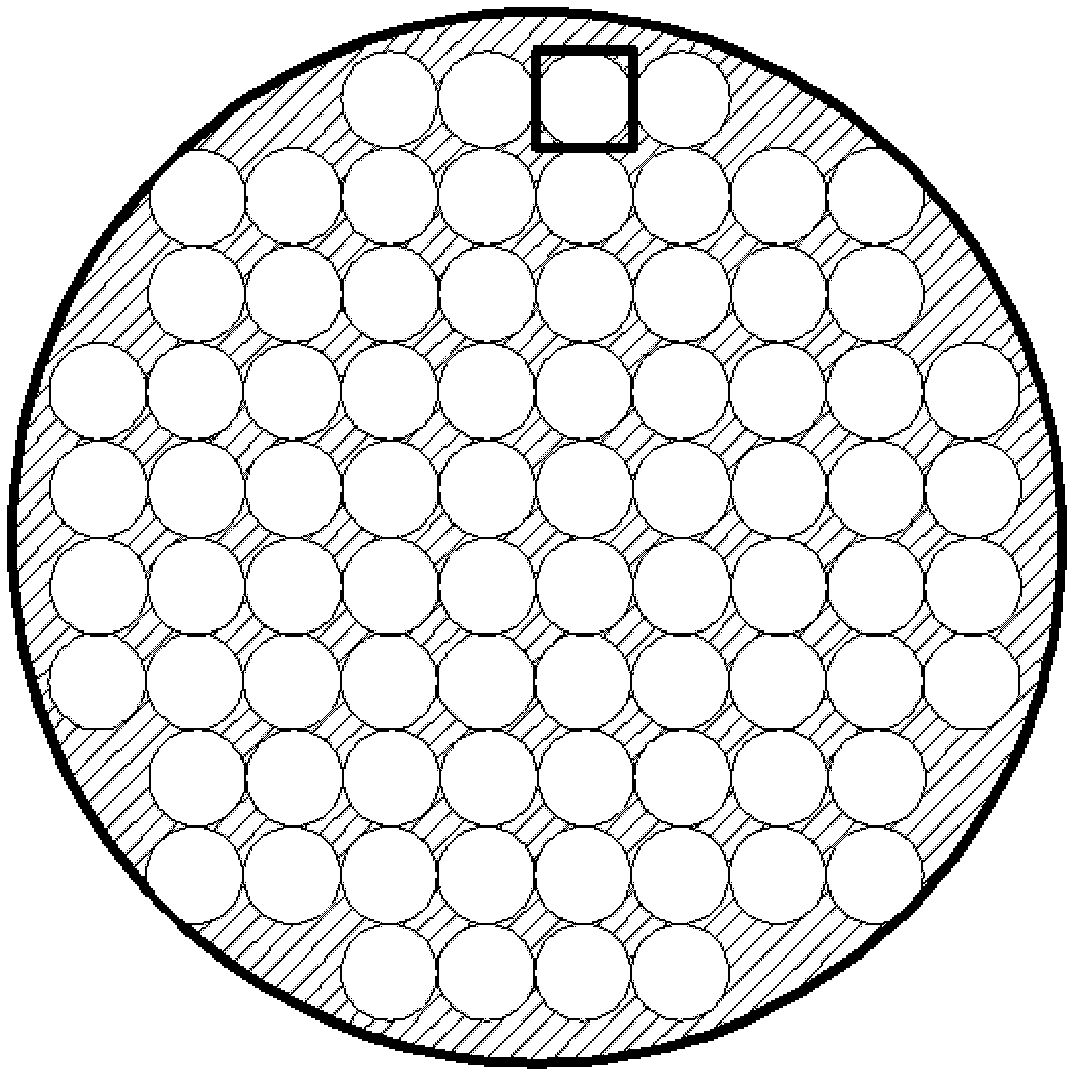

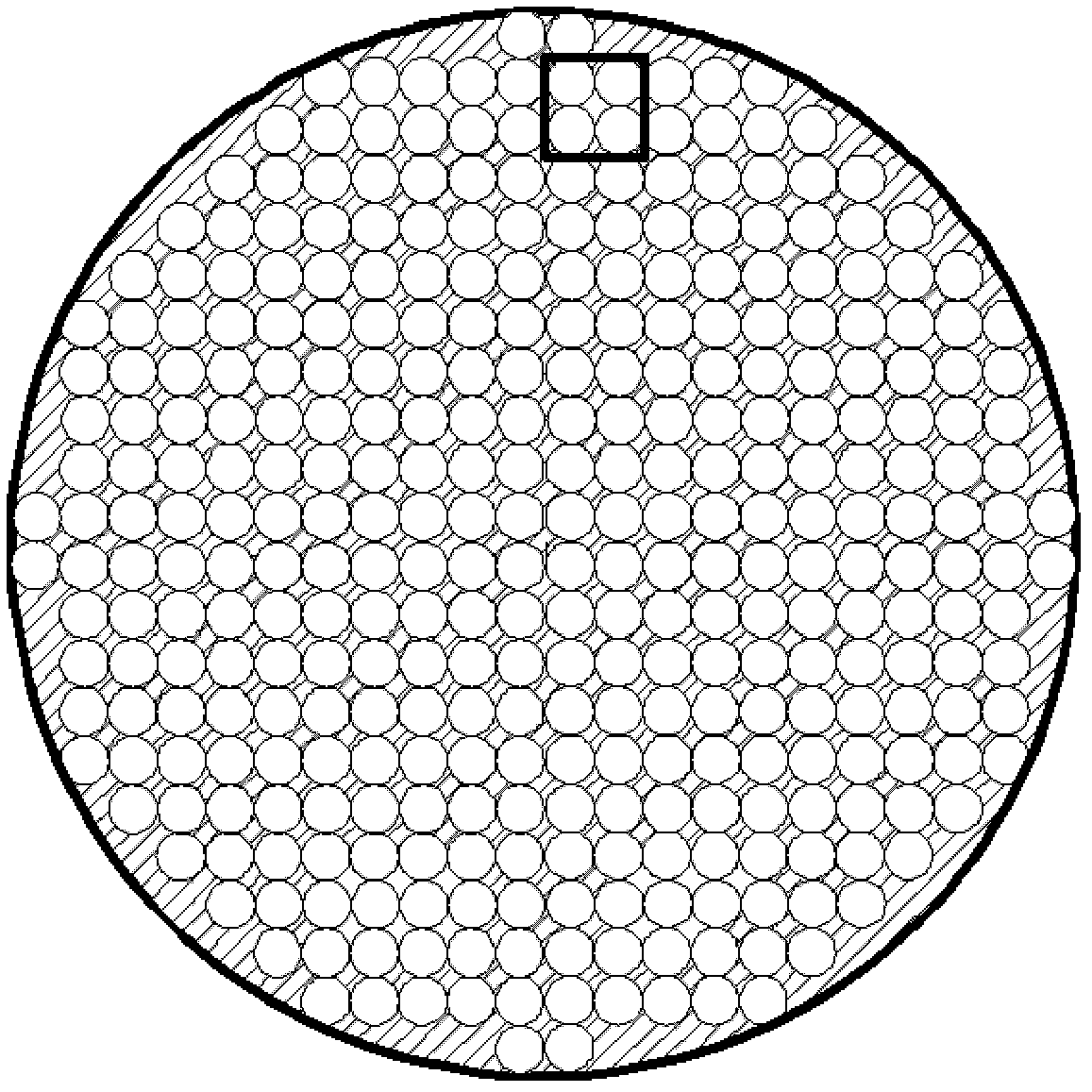

[0030] A magnetic ball 1 with a diameter of 1 cm, a magnetic ball 2 with a diameter of 0.5 cm, a magnetic ball 3 with a diameter of 0.25 cm, a fluidized bed reactor 4, a support plate 5, and a channel 6 for the support plate.

[0031] Using the regular arrangement of magnetic balls of different sizes, different sizes of magnetic balls can be selected according to the needs. In this example 1 model, a layer of magnetic balls 1 with a diameter of 1 cm is selected on the bottom layer, and two layers with a diameter of 0.5 cm are tiled on the top. The magnetic ball 2 is covered with three layers of magnetic balls 3 with a diameter of 0.25 cm. When the fluidization reaction is in progress, the gas or liquid passes through the plate channel 6, and then passes through a layer of magnetic balls 1 with a diameter of 1 cm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com