Vacuum pressurizing and dipping equipment for producing wood plastic composite

A technology of vacuum pressure impregnation and equipment, applied in the direction of pressure impregnation, etc., can solve the problems of cumbersome placement and removal of wood, insufficient impregnation, cumbersome and other problems, and achieve the effects of stable temperature control, pollution reduction, energy saving and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

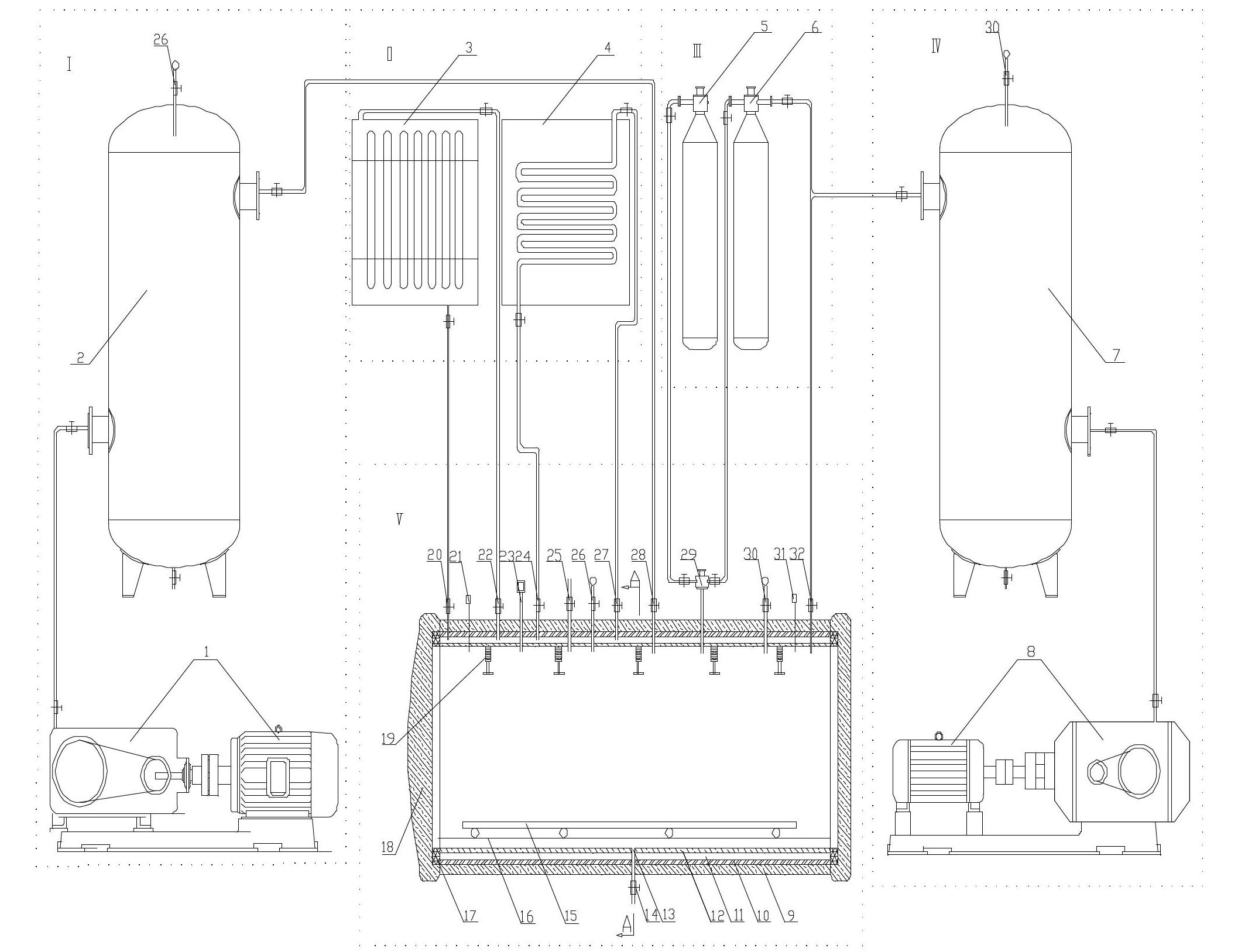

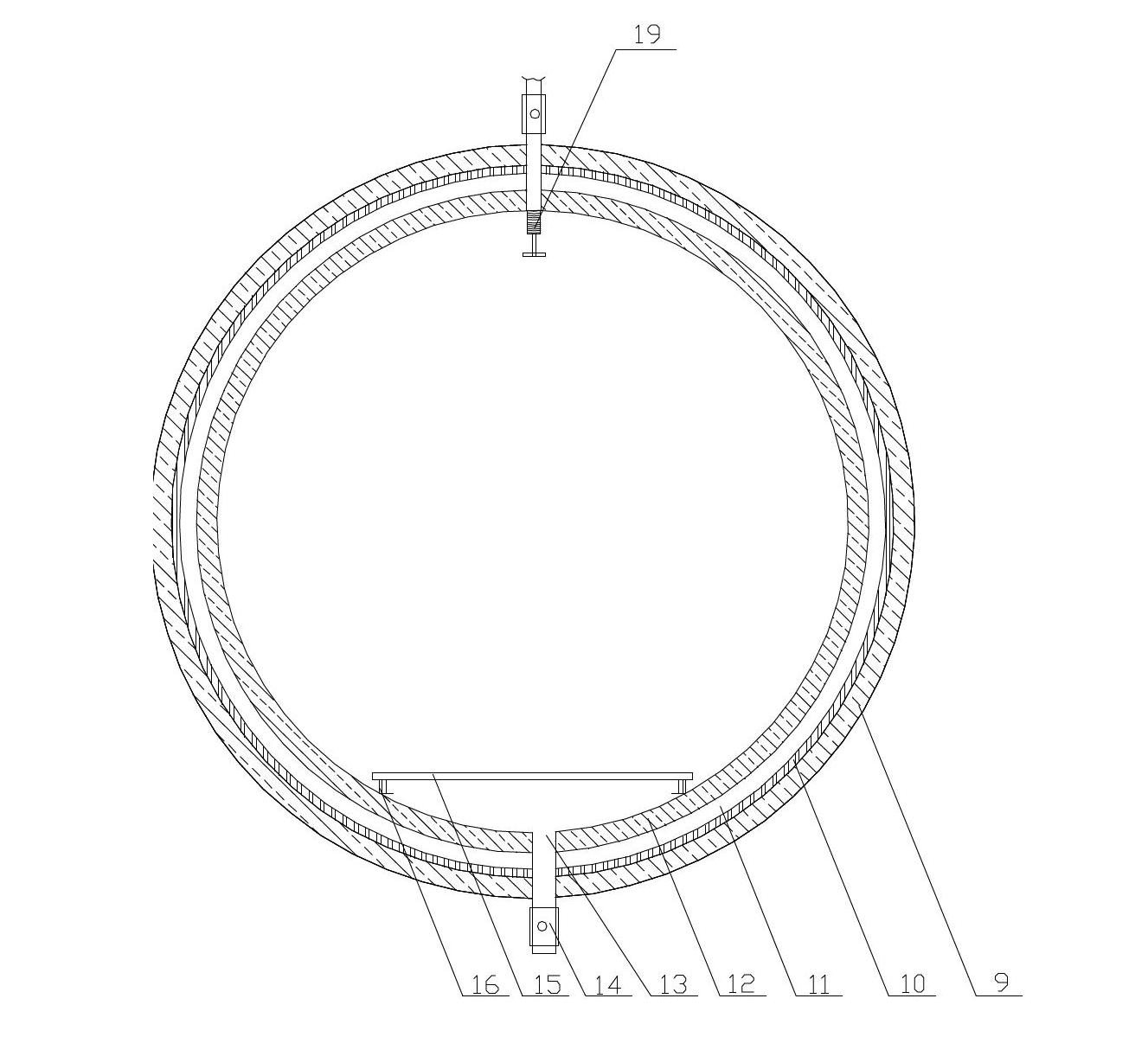

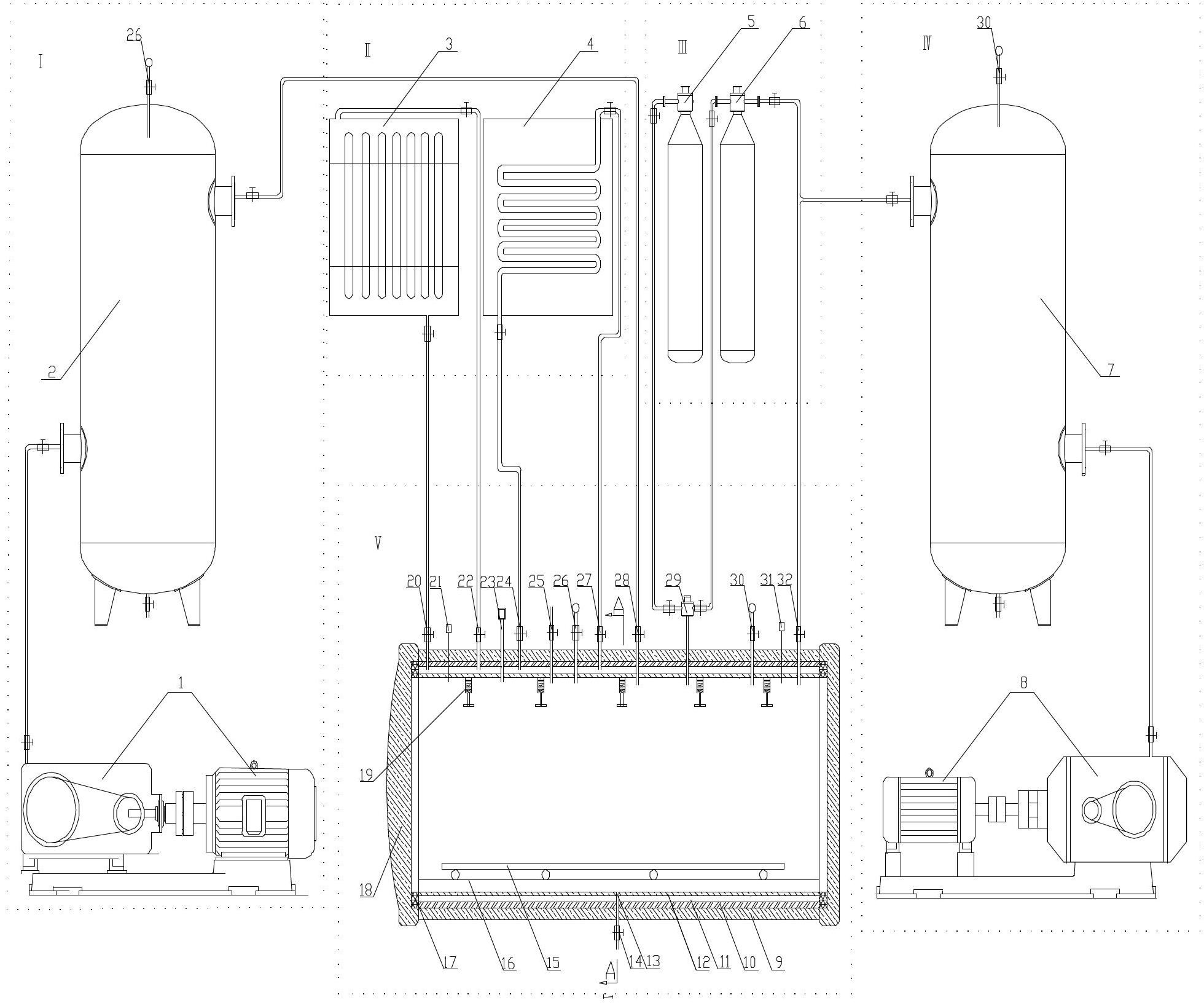

[0009] Specific implementation mode one: vacuum pressure impregnation of wood. to combine figure 1 and figure 2 To illustrate a specific embodiment, the safety valve 23 is opened before the impregnation of wood begins, and remains open throughout the impregnation process. Pull out the pulley 15, put the wood to be impregnated on it and place it, then push it into the tank along the slideway 16, and select the anti-drifting parts with the corresponding length according to the height of the pile against the pile to prevent the impregnation process of wood Float up in the middle, close tank body door 18 again. When it is determined that the valve 14 of the emptying valve 25, the suction / discharge pipe 13, and the pressurizing valve 28 are all closed, the vacuum pump 8, the vacuum buffer tank 7 and the vacuum pressure gauge 30 are opened, and the value of the vacuum gauge vacuum gauge 30 is drawn. To be slightly lower than the required value, open the vacuum valve 32 to vacuum...

specific Embodiment approach 2

[0010] Specific implementation mode two: heating and solidifying to produce plastic composite wood. The same point between this embodiment and specific embodiment one is that the process of impregnating wood under vacuum pressure is the same, and the difference is that the impregnated wood is placed in the tank body 9 for heating and curing, that is, the fixation of the impregnating liquid in the wood . Impregnate wood according to the method of mode 1, put the impregnated wood in the tank body 9, close the tank body door 18, open the heating medium inlet valve 20, and the heating medium outlet valve 22, so that the heating medium circulates continuously on the simplified body 12 Heating, insulation layer 10 maintains a stable temperature until the required temperature, if the temperature is too high, the cooling medium inlet valve 24 and the cooling medium outlet valve 27 will be automatically opened and adjusted to the required temperature, so that the temperature inside the...

specific Embodiment approach 3

[0011] Specific implementation mode three: Protect with inert gas when producing plastic composite wood. The same point between this embodiment and specific embodiment 1 and specific embodiment 2 is that the process of vacuum pressure impregnation of wood is consistent, and the difference with specific embodiment 2 is that this embodiment needs to add protective gas, which has the effect of Reduce the inhibitory effect of oxygen on the impregnating liquid in wood, and reduce the cracking and thermal degradation of wood after joining and curing. According to the methods of Embodiment 1 and Embodiment 2, the wood is first impregnated, then heated for curing, and then the inert gas tank 5 and the inlet valve of the protective gas inlet / outlet valve 29 are opened to allow the protective gas to slowly enter the impregnated tank body 9, and then close. After the reaction is finished, open the inert gas collection tank 6 and the outlet valve of the protective gas inlet / outlet valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com