Automatic welding platform for double annular welding seams and welding process

A welding platform and automatic welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of long processing procedures, low production efficiency, and large occupied space, and achieve high automation, convenient operation, and strong interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

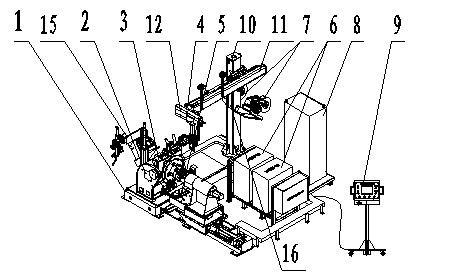

[0027] The present invention consists of a welding platform mechanical part and a welding platform control system. The main components of the welding platform mechanical part are as follows: a bed 1, a displacement mechanism 2, a pneumatic clamp 3, a welding torch control mechanism 16, a pneumatic feeding and unloading platform 5, and a welding power supply 6. It is composed of wire feeding mechanism 7, program control system 8, operation box 9, column 10, fixed welding torch control mechanism 15 and so on.

[0028] The displacement mechanism 2 is adjacent to the pneumatic feeding and unloading platform 5, and the two are respectively installed in front of the bed 1 by bolts, the pneumatic clamp 3 is installed on the displacement mechanism 2, and the clamping station of the pneumatic clamp 3 is connected to the The position of the feeding station of the pneumatic feeding and unloading platform 5 corresponds; a first welding torch control mechanism 16 is provided behind the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com