High-frequency non-inductive resistor

A technology of non-inductive resistors and resistors, applied in the direction of resistors, liquid resistors, resistor components, etc., can solve problems such as not being able to meet the on-load test and affecting the on-load measurement results of high-frequency equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

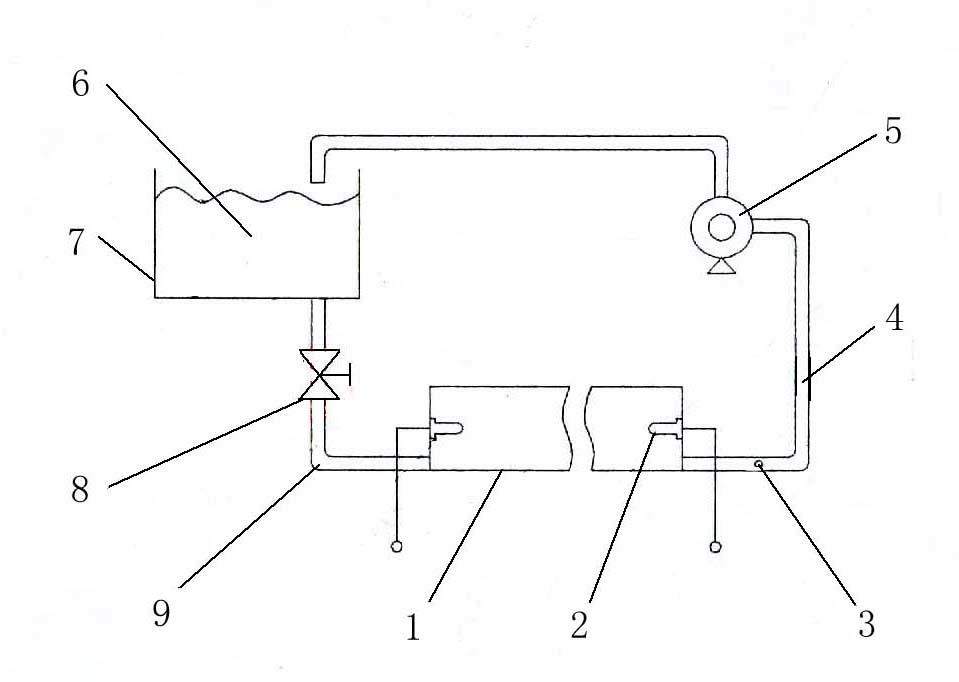

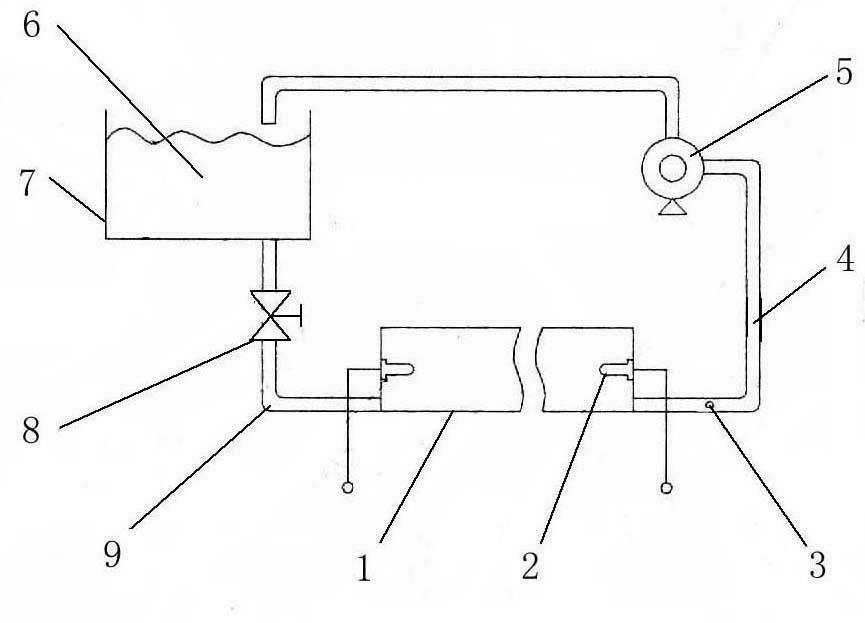

[0017] Depend on figure 1 It can be seen from the illustrated embodiment that it includes a resistor housing 1 containing brine, a columnar electrode 2 mounted on the left and right side walls of the resistor housing 1, a circulation pump 5, a water tank 7 containing brine, and a temperature sensor 3 The water tank 7 is located above the resistor housing 1, the water inlet on the left side wall of the resistor housing 1 communicates with the bottom of the water tank 7 through the water inlet pipe 9, and the right side of the resistor housing 1 The water outlet on the side wall communicates with the top of the water tank 7 through the water outlet pipe 4 equipped with the circulation pump 5, and the temperature sensor 3 is installed on the water outlet pipe at the water outlet on the right side wall of the resistor housing 1 4 on.

[0018] A valve 8 is installed on the water inlet pipe 9 .

[0019] The resistor housing 1 is tubular, and its material is insulating engineering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com