Sunlight conveyor for direct illumination of basement

A technology for basements and conveyors, applied in the direction of using feedback control, etc., can solve problems such as poor effect, and achieve the effects of system cost reduction, social benefits of energy saving and emission reduction, and great practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

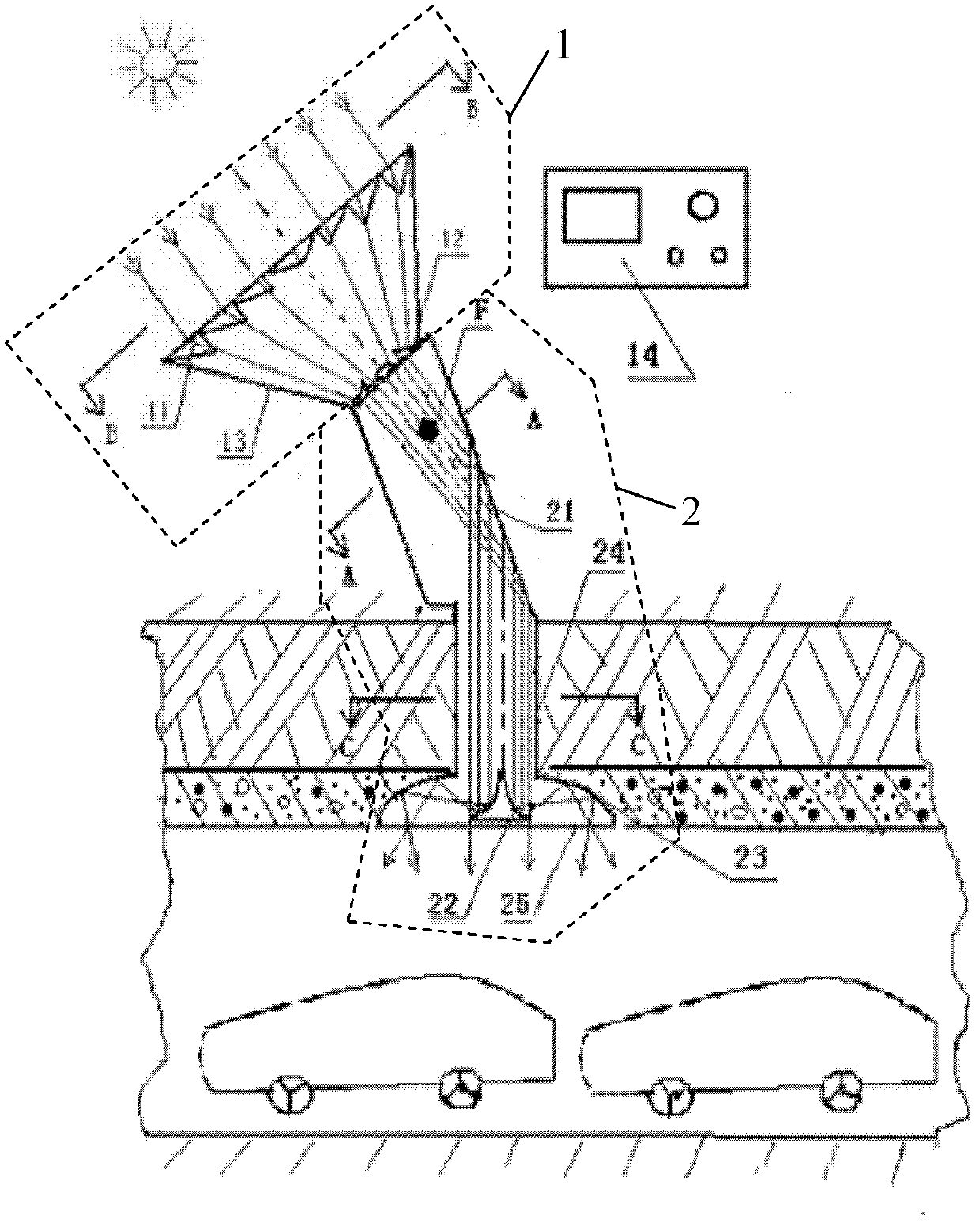

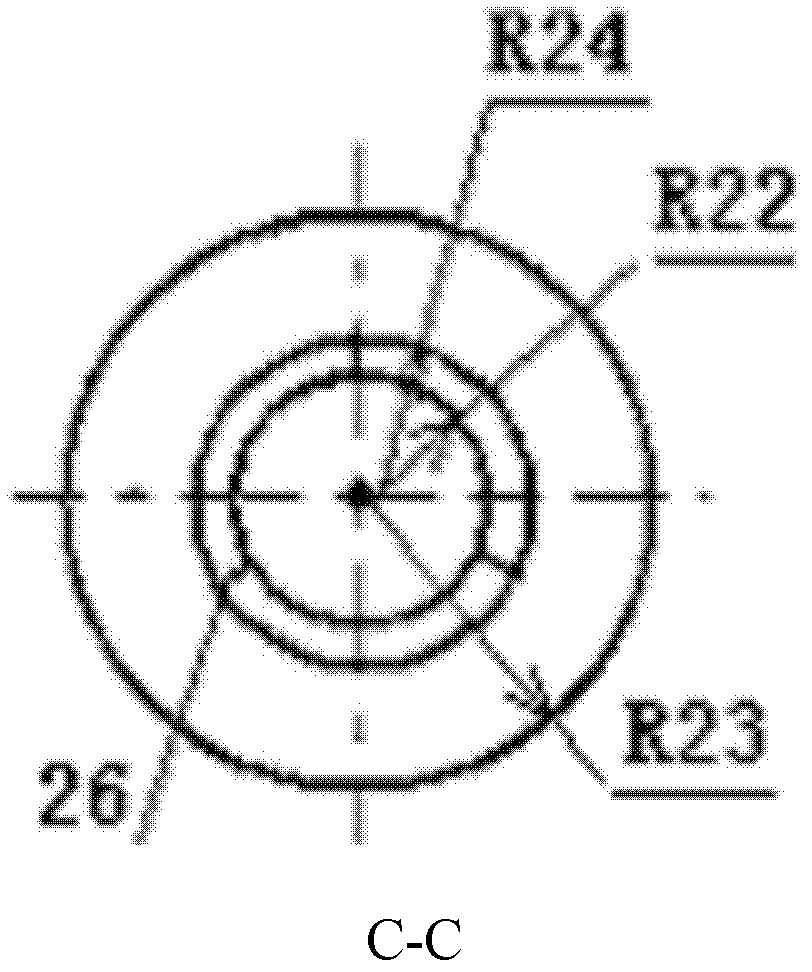

[0019] see Figure 1-4 , this kind of sunlight conveyor used for direct lighting in the basement includes a polar coordinate type sunlight automatic tracking system 14, and the polar coordinate type sunlight automatic tracking system 14 is connected with several concentrators 1 arranged on the ground, and the concentrators The light output end of 1 is connected with the light input end of light guide 2, and light guide 2 extends into the basement and its light output end is arranged on the ceiling of the basement as an illumination surface.

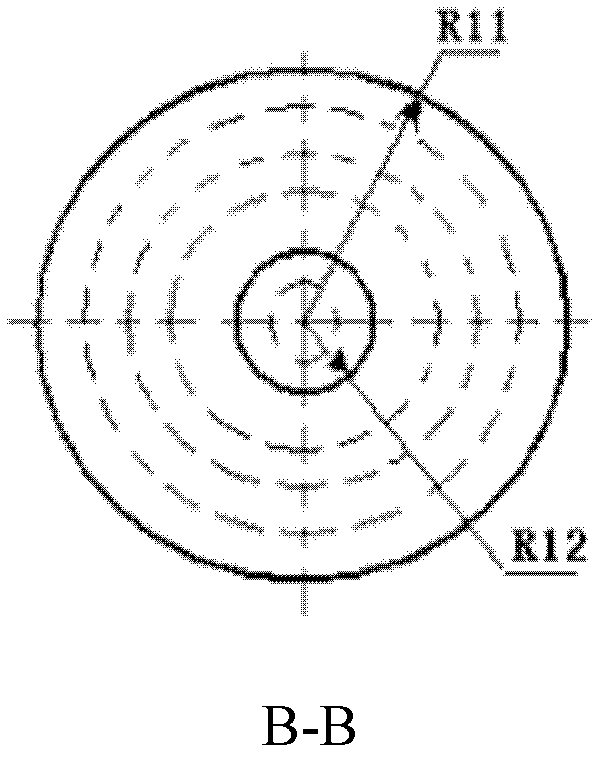

[0020] The concentrator 1 includes a trumpet-shaped closed curved surface 13, a Fresnel point condenser lens 11 is arranged on the opening facing the sun at the upper end of the closed curved surface 13, and a Fresnel dimmer mirror 12 is arranged at the bottom end of the closed curved surface 13 Fresnel point converging lens 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com