Rock three-way pressure stress sensor based on optical fiber grating sensing

A three-dimensional compressive stress and fiber grating technology is used in the stress test of soft rock and soil, and the field of geotechnical three-dimensional compressive stress sensor, which can solve the problem of unsatisfactory application effect of rock and soil stress test method and device, and easy electromagnetic interference. , The sensor stability is not good enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment describe in detail:

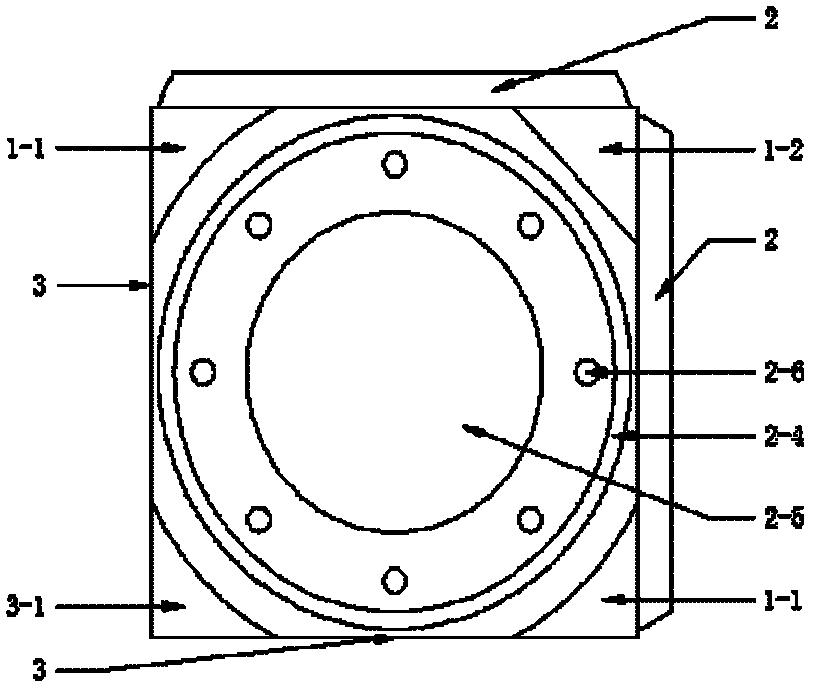

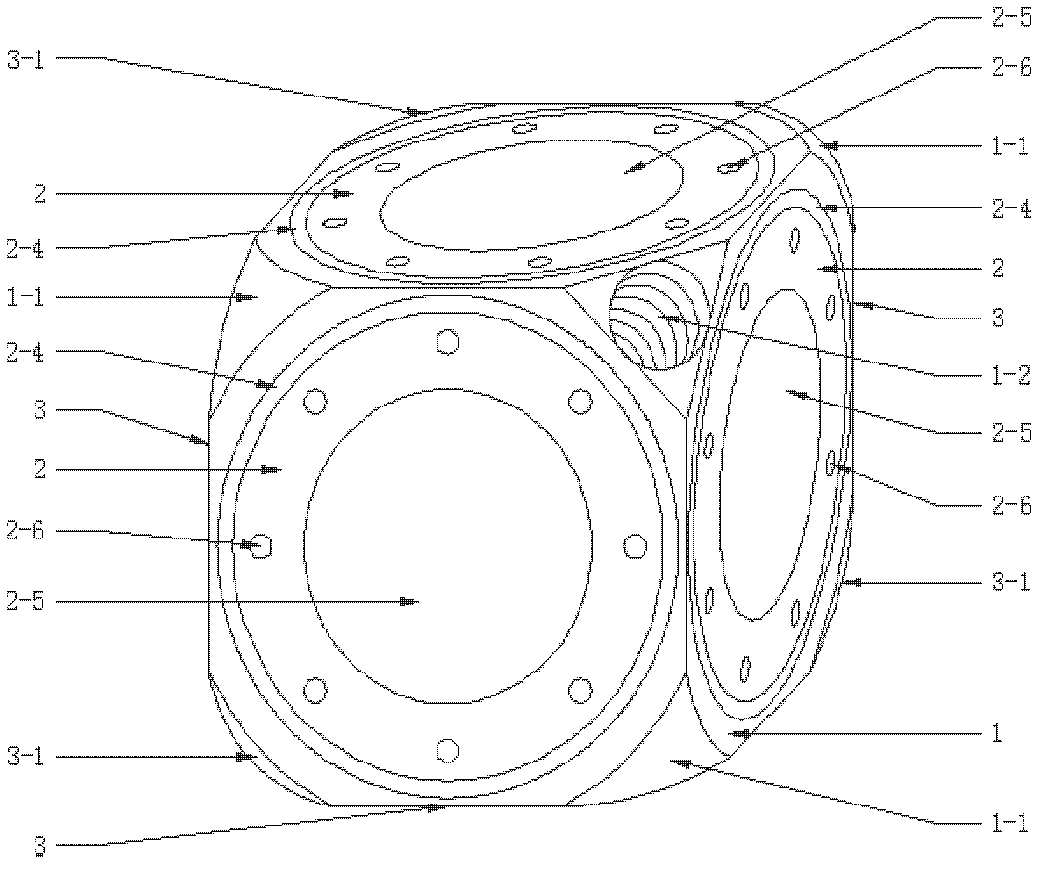

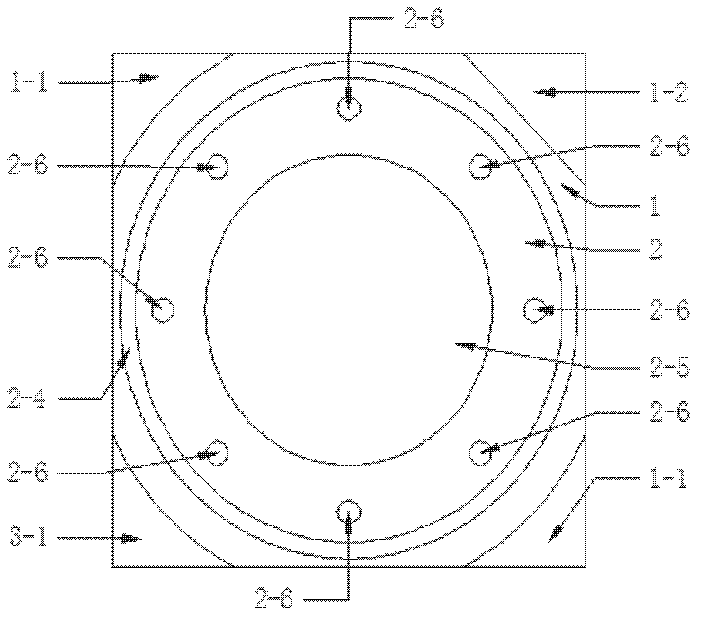

[0043] A geotechnical three-way compressive stress sensor based on fiber grating sensing, comprising a cubic box body 1, the box body 1 has six surfaces, and the three surfaces with common vertices are the force-bearing surface 3, and the force-bearing surface 3 is a plane, In addition, the three faces of the common vertices each have a concave disc 1-4, and three sensing films 2 are respectively connected on the concave discs (1-4) of the three faces; the three sensing films 2 are circular structures, and the middle The small round thin plate is an effective pressure-bearing surface 2-5, and its inner surface is pasted with a fiber grating (FBG) 2-2, and the sensing film 2 is installed on the box body 1 through screws 2-6. The specific connection relationship is: the cube box body 1 has six surfaces, among which the three force-bearing surfaces 3 with common vertices are connected to ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com