Coil tumbling solar dryer with auxiliary heating

An auxiliary heating and solar energy technology, applied in solar thermal power generation, solar thermal installations, dry gas arrangement, etc., can solve the problems of low utilization rate of solar energy, decreased product quality and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

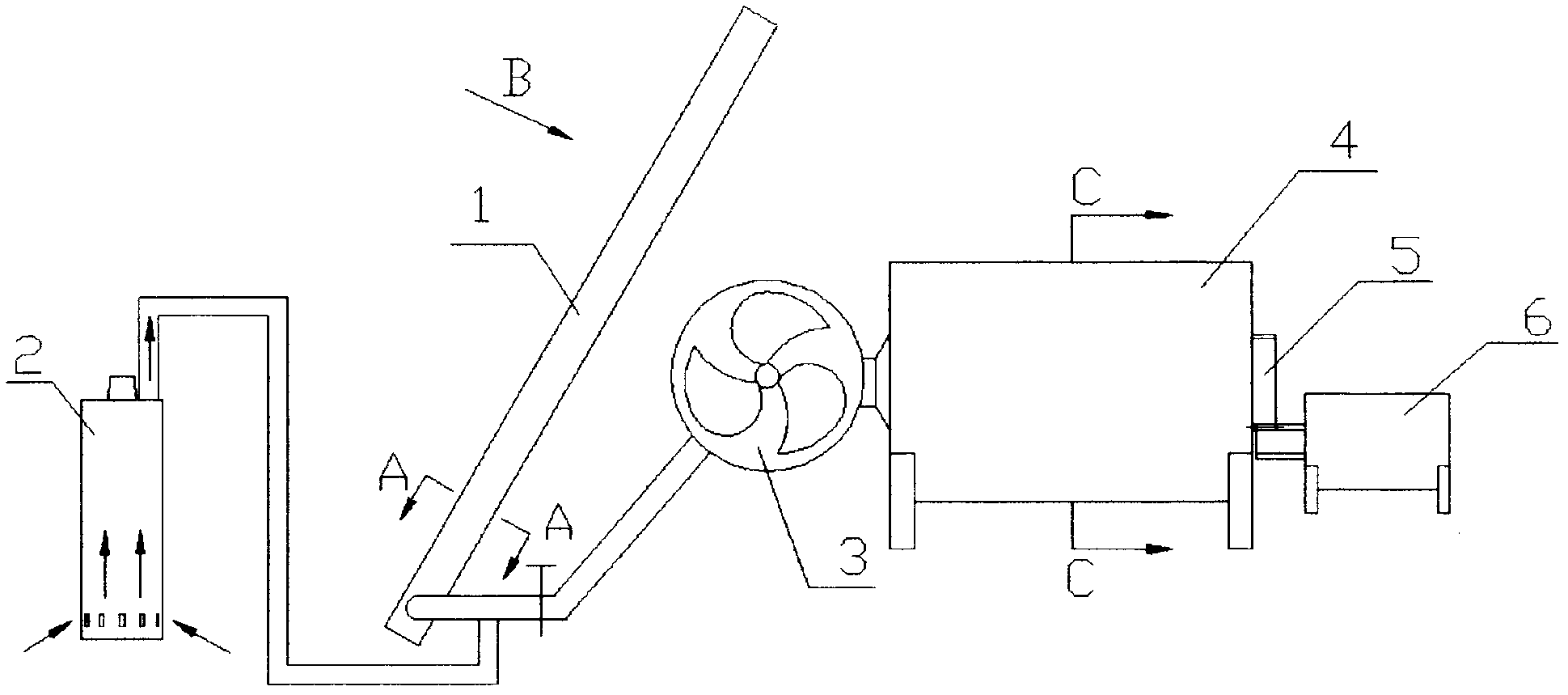

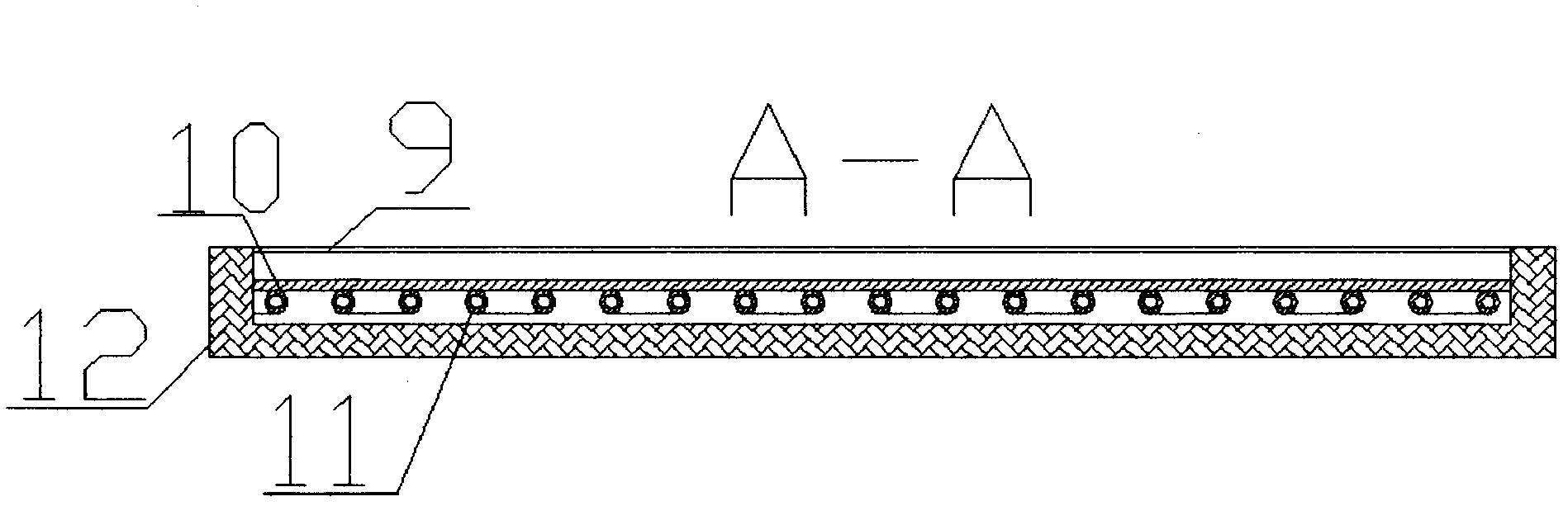

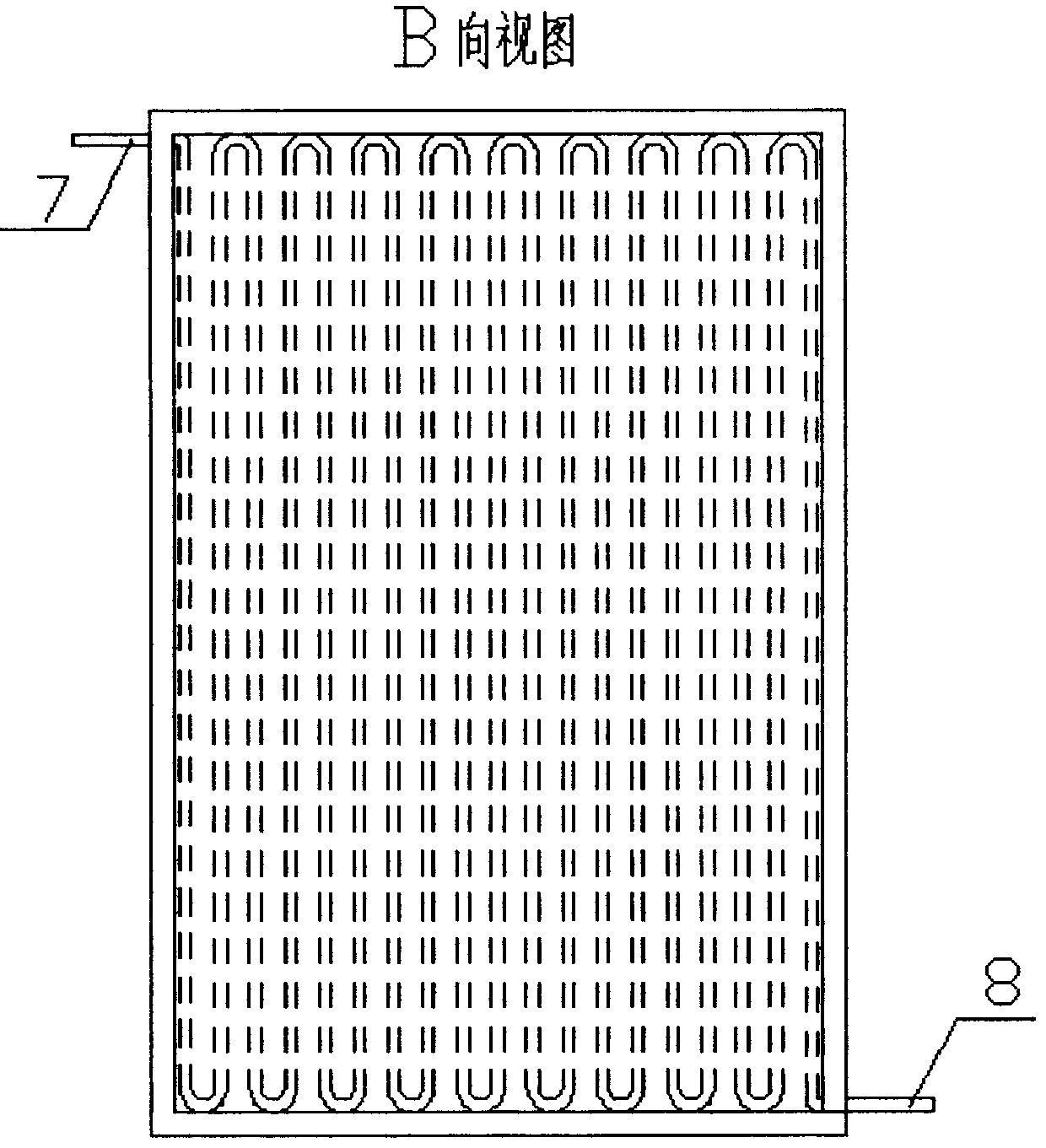

[0016] In this device, a serpentine solar air heat collector 1 is used as a main heat source, and an air heating furnace 2 is used as an auxiliary heat source. The ventilation pipes of the heat collector and the heating furnace are respectively equipped with valves. When the light is sufficient, the blower fan 3 is started, and the hot air is extracted from the coil type solar air heat collector 1 and sent to the tumbling drying bin 4 to dry goods. Outside air enters the serpentine elbow 11 from the air inlet 7 at the upper end of the serpentine solar air heat collector 1 , and after absorbing heat in the serpentine elbow 11 , enters the fan 3 through the air outlet 8 of the heat collector through the ventilation duct 2 . The tumbling drying bin 4 rolls under the drive of the motor 6, so that the dried objects inside are also tumbling thereupon. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com