Totally-sealed fiber expansion joint with novel trim strip

A technology of fiber expansion and full sealing, which is applied in the field of fiber expansion joints, can solve the problems of laborious and low efficiency, and achieve the effects of improving production efficiency, prolonging service life and soft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

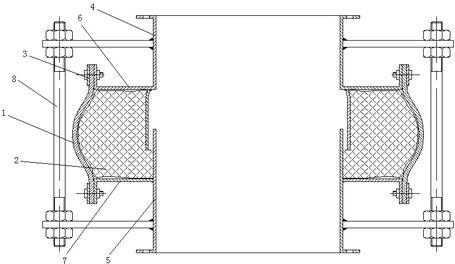

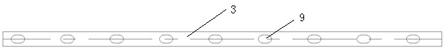

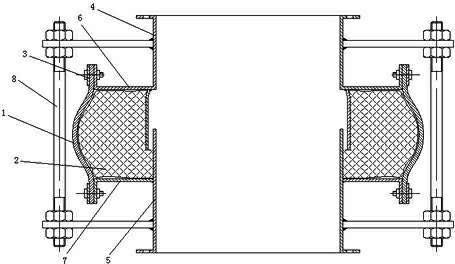

[0016] see figure 1 and figure 2 , this fully-sealed fiber expansion joint with new beading includes ring belt 1, insulation layer 2, beading 3, upper connecting pipe 4, lower connecting pipe 5, upper ring plate 6, lower ring plate 7 and tie rod 8, and tie rod 8 passes through the bracket They are respectively fixedly connected with the upper connecting pipe 4 and the lower connecting pipe 5, the upper ring plate 6 is vertically fixedly connected with the upper connecting pipe 4, the lower ring plate 7 is vertically fixedly connected with the lower connecting pipe 5, the upper end of the lower connecting pipe 5 extends into the upper connecting pipe 4, and the bead 3 There are at least two fixing holes 9, and the bead 3 seals and fixes both sides of the ring belt 1 on the upper ring plate 6 and the lower ring plate 7 respectively through the fixing holes 9, that is, the bead 3 and the upper ring plate 6 and the lower ring plate 7 Sealed connection, the upper connection pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com