Pure-water bidirectional opposed piezoelectric ceramic reversing valve

A technology of piezoelectric ceramics and reversing valves, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the limitations of the application and development of piezoelectric servo valves, small output displacement of piezoelectric drivers, and piezoelectric materials. Large hysteresis effect and other problems, to achieve the effect of improving dynamic and static performance, hydraulic pressure balance, and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

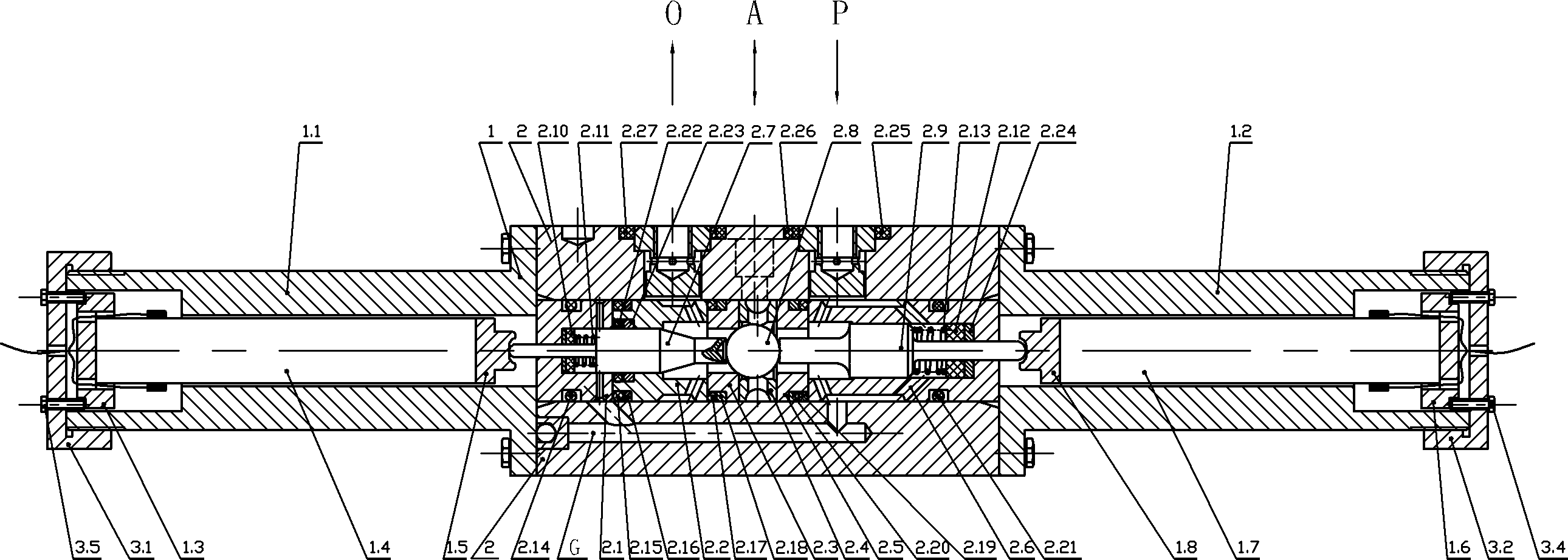

[0027] Such as figure 1 The shown pure water two-way opposing piezoelectric ceramic reversing valve of the present invention includes an external fixed valve sleeve 1, a valve body 2 and a fixed nut 3; External fixed valve sleeve I 1.1 and external fixed valve sleeve II1.2; fixed nut 3 includes, nut I 3.1 fixed on the axial left end of external fixed valve sleeve I 1.1 and nut II3 fixed on the right end of external fixed valve sleeve II1.2 .2; There is a through hole in the inner axis of the valve body 2, and a two-hole valve sleeve with a set of through holes in the radial direction is installed sequentially from left to right in the through hole 2.1 Six holes with a set of oblique holes in the radial direction Valve sleeve 2.2, step column I 2.3, eight-hole valve sleeve 2.4 with a set of through holes in the radial direction, step column II 2.5 and spring valve sleeve 2.6 with two sets of oblique holes in the radial direction, and two-hole valve sleeve 2.1, Six-hole valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com