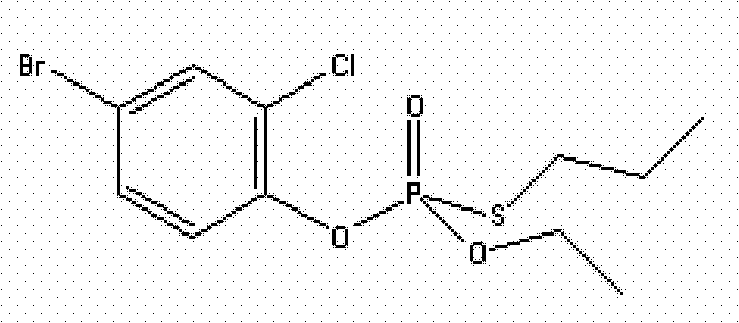

Preparation method of high-purity profenofos

A profenofos, high-purity technology, applied in the field of profenofos preparation, can solve the problems such as the reduction of profenofos purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

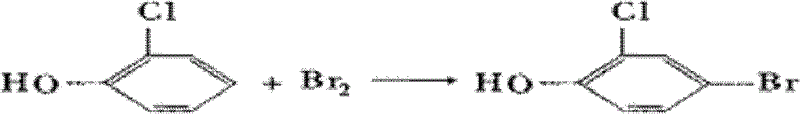

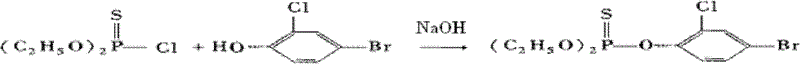

[0023] 1) O-chlorophenol and Br with a molar ratio of 1:1 2 reaction, the reaction temperature is 30°C, and the reaction time is 25 hours to obtain a brominated product, wherein the brominated product includes 94-95 mass % of 2-chloro-4-bromophenol and 3-4 mass % of by-product 2-chloro -6-bromophenol and 2-3% by mass of polybrominated by-products;

[0024] 2) Recrystallization: Slowly heat the brominated product obtained in step 1, so that the brominated product is heated up at a rate of 0.8°C / hour, stop heating when the brominated product temperature reaches 48°C, and then naturally cool down until the brominated product temperature reaches 42 ℃, the above-mentioned process of slowly heating up and then naturally cooling down is called the recrystallization process, and repeat the recrystallization process 2 times; repeated recrystallization 3 times can separate part of 2-chloro-6-bromophenol and polyphenol from the brominated product. Brominated by-products, the purity of 2...

Embodiment 2

[0030] 1) O-chlorophenol and Br with a molar ratio of 1:1 2 reaction, the reaction temperature is 50°C, and the reaction time is 20 hours to obtain brominated products, wherein the brominated products include 94-95% by mass of 2-chloro-4-bromophenol and 3-4% by-product 2-chloro -6-bromophenol and 2-3% by mass of polybrominated by-products;

[0031] 2) Recrystallization: Slowly heat the brominated product obtained in step 1) to raise the temperature of the brominated product at a rate of 1.0°C / hour, stop heating until the temperature of the brominated product reaches 50°C, and then cool down naturally until the temperature of the brominated product reaches 43 ℃, the above-mentioned process of slowly heating up and then naturally cooling down is called the recrystallization process, and repeat the recrystallization process 4 times; repeated recrystallization 5 times can separate part of 2-chloro-6-bromophenol and polyphenols from brominated products. Brominated by-products, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com