Monitoring system and dynamic detection equipment thereof for medium-low magnetic suspension train contact rail

A technology for magnetic levitation trains and dynamic detection, which is applied in railway auxiliary equipment, railway vehicle shape measuring instruments, measuring devices, etc., can solve the problems of inapplicability of detection equipment, large fluctuation, and detection failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

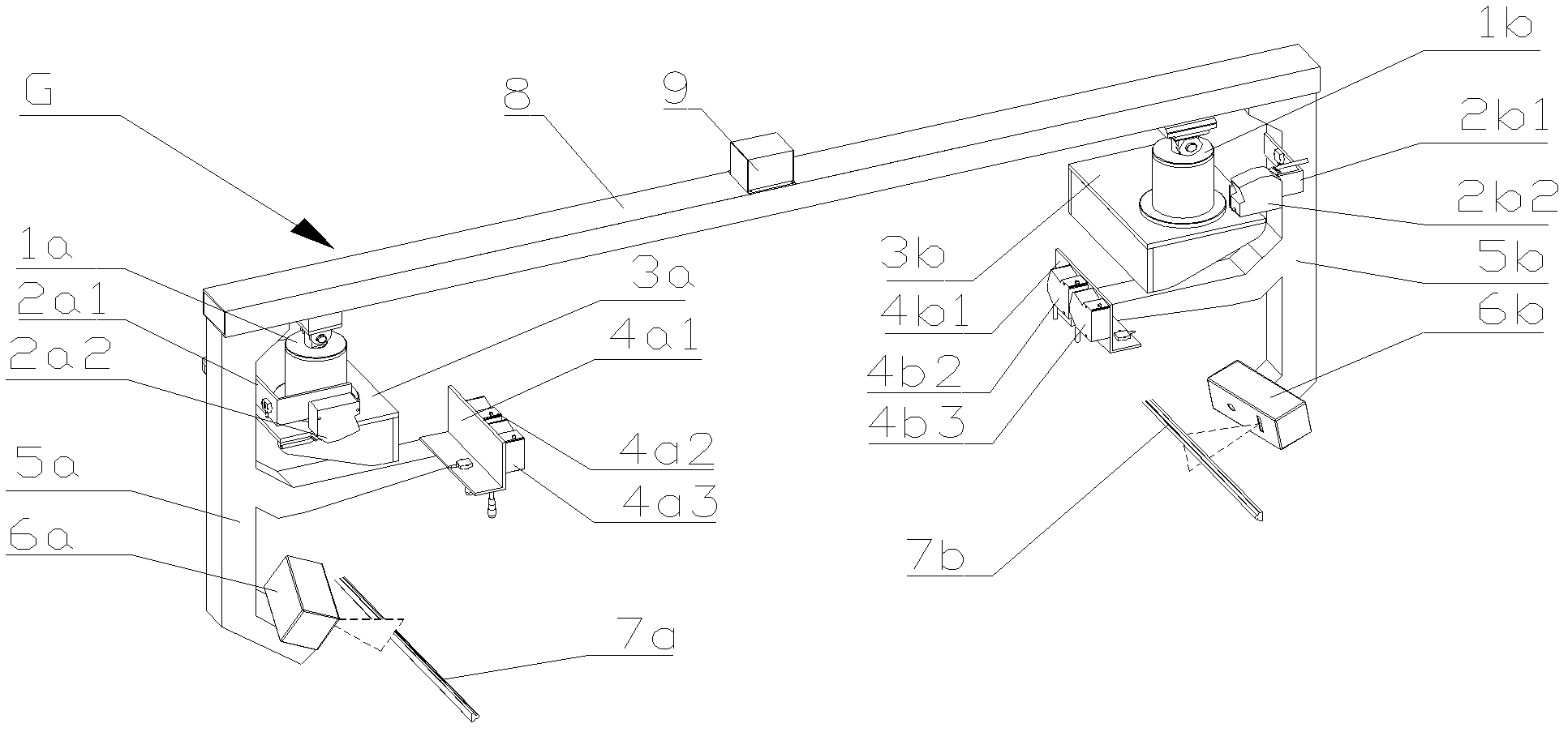

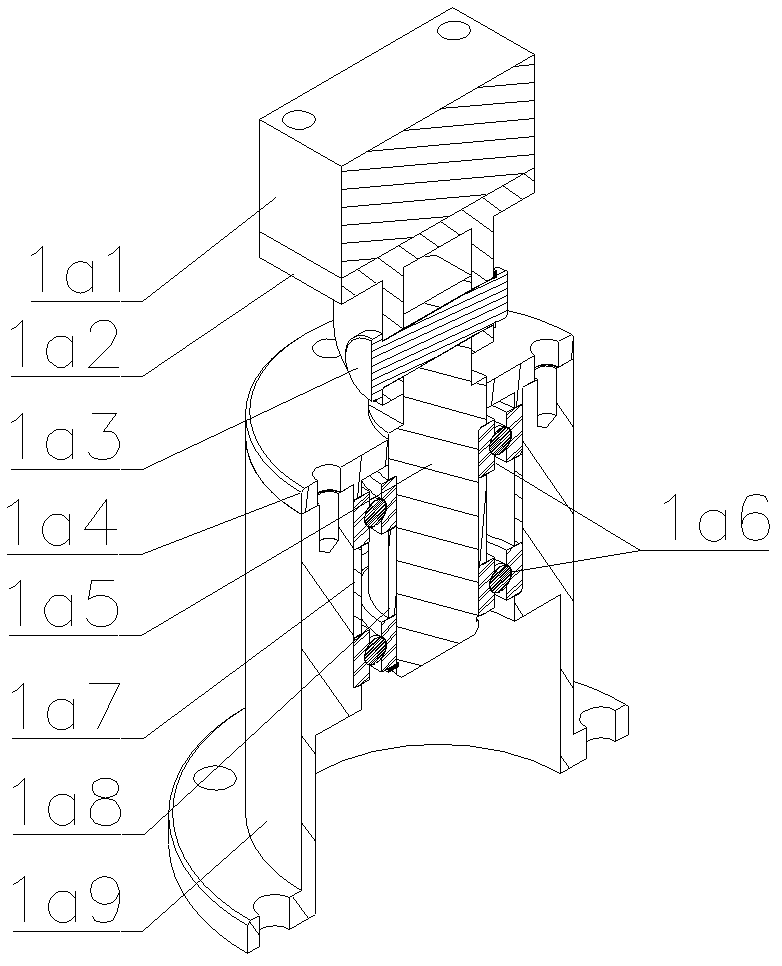

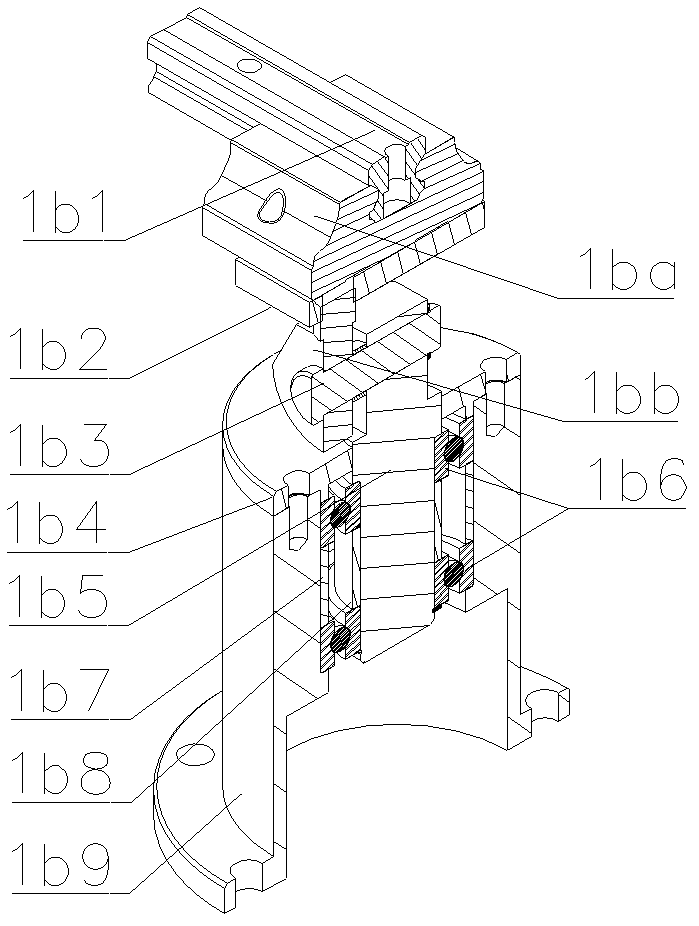

[0042] The core of the present invention is to provide a dynamic detection device for a contact rail of a medium-low speed maglev train. The detection device can be adapted to the dynamic working conditions of the bogie of this kind of train and truly reflect the real state of the contact rail.

[0043] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For ease of understanding and brevity of description, the article combines the monitoring equipment of the contact rail of the medium and low-speed maglev train and its dynamic detection equipment for description, that is, the description of the overall monitoring system, and the beneficial effects will not be repeated. In addition, it should be noted that the "left" and "right" mentioned in the embodiments of the text all refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com