Gear shaft overhauling and washing device

A technology for cleaning devices and gear shafts, used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as insufficient efficiency, low efficiency, and easy generation of iron filings and garbage, and reduce abnormal noise. The number of occurrences, the reduction in the frequency of rework, the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

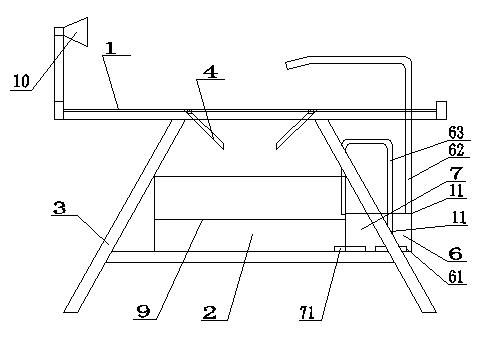

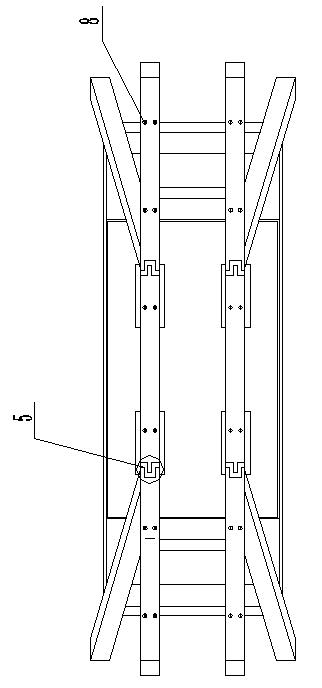

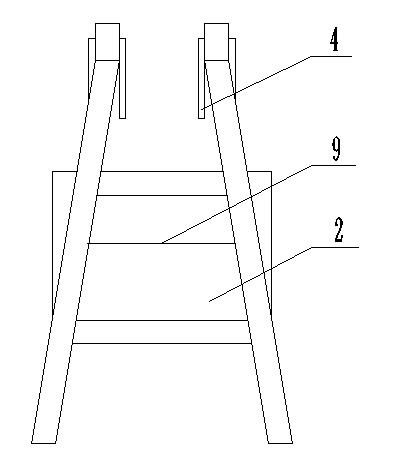

[0018] like figure 1 and image 3 As shown, a gear shaft inspection and cleaning device includes a bracket 3 and a work surface 1, an oil tank 2, an oil pump 7 and a safety valve 6 are welded on the bracket 3, and an oil pump inlet pipe 71 is provided on the oil pump 7. The safety valve 6 is provided with a safety valve oil inlet pipe 61, a safety valve oil outlet pipe 62 and a safety valve oil return pipe 63, and the two boundaries of the maintenance area of the work surface 1 are provided with a concave oil return groove 5 (such as figure 2 ) and drainage tube 4. The cleaning device is equipped with an oil tank, an oil pump and a safety valve so that the gear shaft can be cleaned with pressure-controllable clean kerosene before maintenance.

[0019] Described fuel tank 2 is provided with filter screen 9 (as figure 1 ). At the two boundaries of the maintenance area of the inspection and cleaning table, there are concave oil return tanks and drainage pipes with a dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com