Flue gas cleaning device and method for circulating fluidized bed through semi-dry method

A circulating fluidized bed and flue gas purification technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of inability to accurately control the flue gas volume of the desulfurization tower, low degree of automation, and poor desulfurization effect. The effect of improving utilization rate and desulfurization efficiency, low production cost and smooth system layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

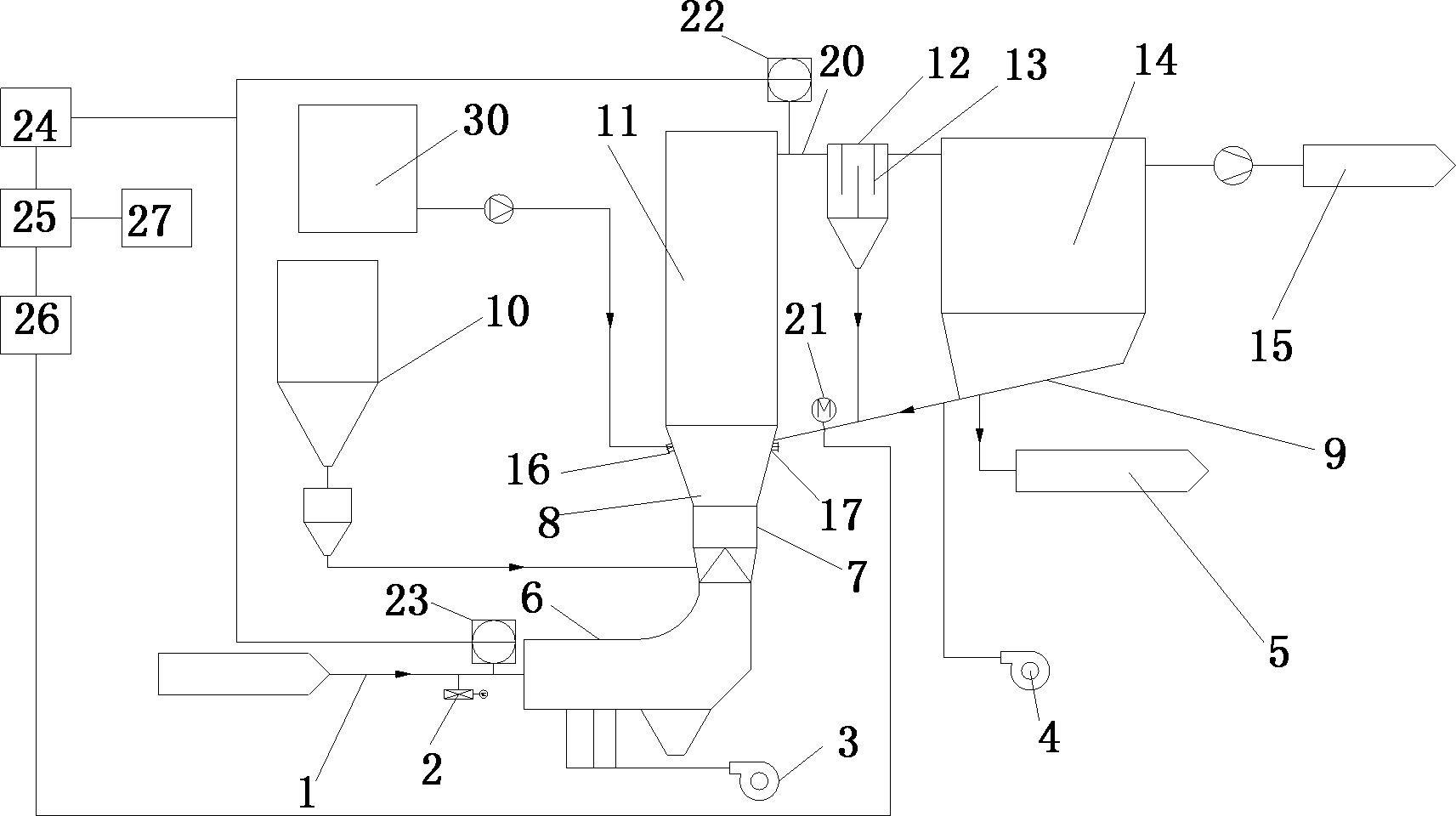

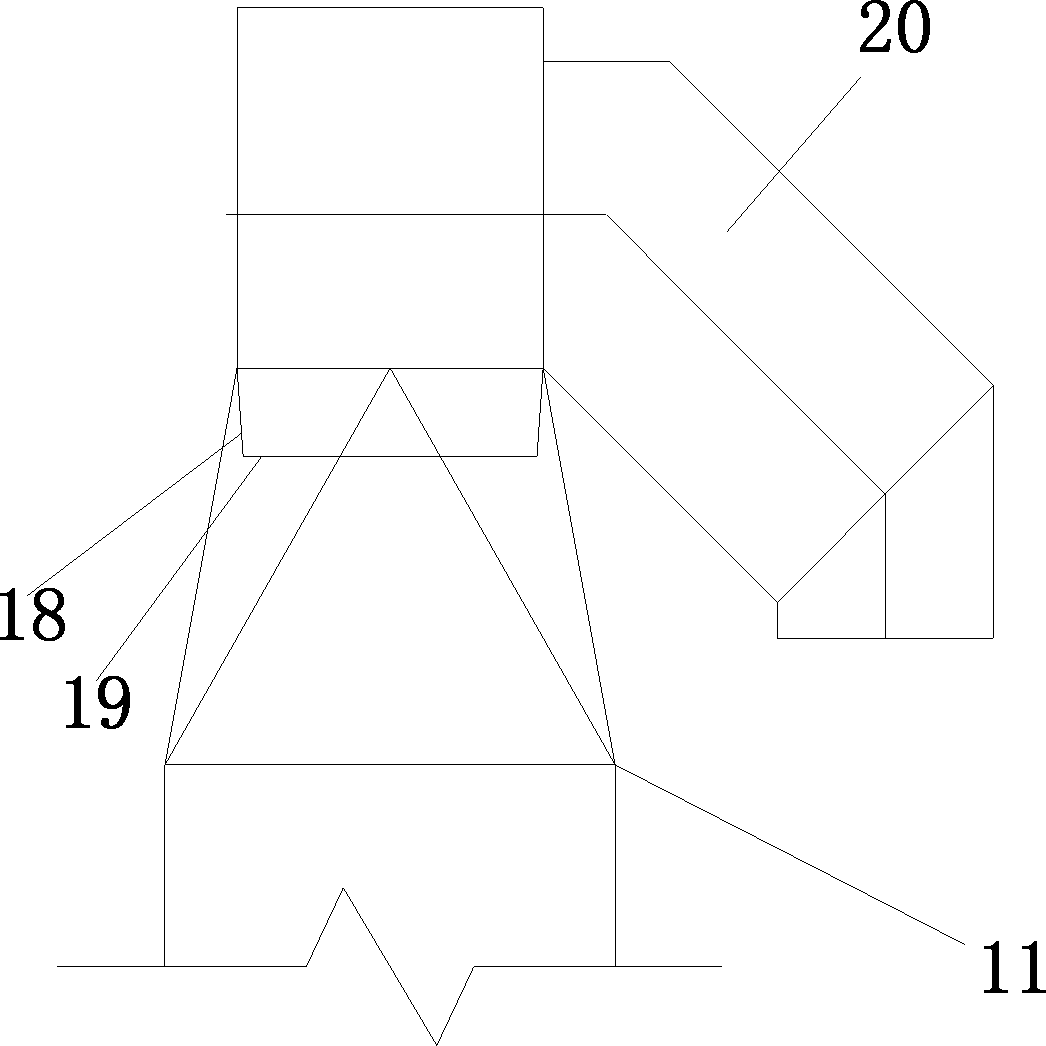

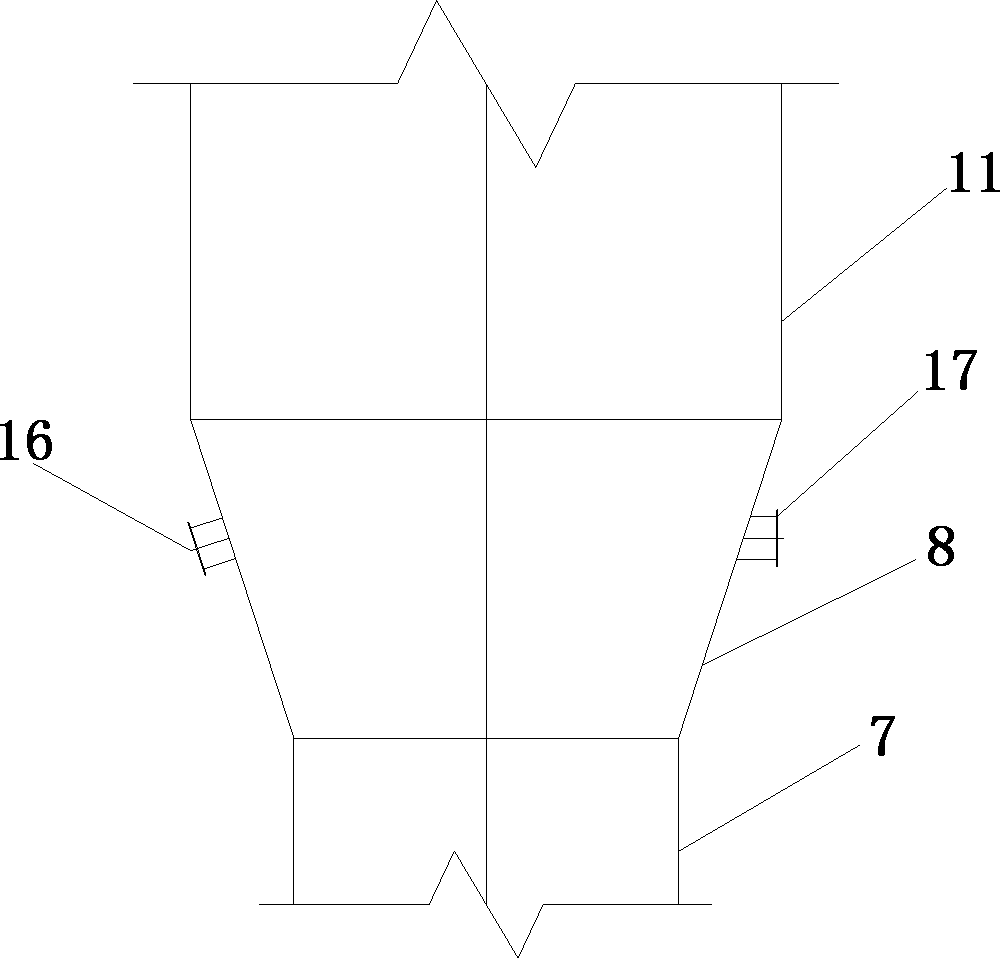

[0028] Example. Circulating fluidized bed semi-dry flue gas purification method, the flue gas from the boiler room is desulfurized by the desulfurization tower, pre-dusted by the pre-dust removal device, and dusted by the bag filter, and then discharged to the chimney; the desulfurized ash collected after the pre-dust removal and dust removal Return to the desulfurization tower through the air chute to continue desulfurization and discharge to the ash storage. The desulfurization method of the desulfurization tower is to use a weighing sensor to measure the absorbent and transport it to the Venturi inlet of the desulfurization tower through the jet pump by the Roots blower to mix with the flue gas, and then transmit it to the diffusion section from the Venturi, and then from the diffusion section. The desulfurization nozzle and the reserved nozzle alternately spray water mist for desulfurization.

[0029] The desulfurization nozzle and reserved nozzle are arranged opposite to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com