Preparation device and application method of triaxial test sample provided with structure in contact with soil

A technology of triaxial sample and preparation device, which is applied in the preparation of test samples and other directions, can solve problems such as affecting work efficiency, dam breaking, and soil cannot be compacted uniformly and effectively, and achieves the goal of ensuring preparation quality and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

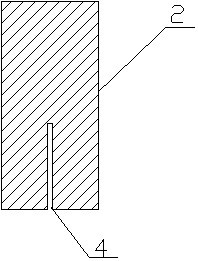

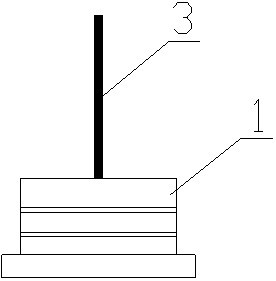

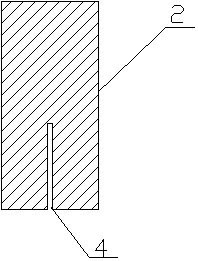

[0014] Such as figure 1 and 2 As shown, a soil-structure contact triaxial sample preparation device includes a sample base 1, a structure to be simulated 3, a rubber membrane, a split mold and a steel cylinder 2 with the same diameter as the triaxial sample One end of the steel cylinder 2 has a narrow groove 4 completely consistent with the width and height of the structure 3 to be simulated.

[0015] The specific steps of using the preparation device are as follows: (1) Install the sample base 1, the rubber film and the split mold, hoop one end of the rubber film on the sample base 1, and install the rubber film outside the rubber film. The split mold is described, and the split mold is tightened to form a compacting cylinder, the rubber film is arranged to be smooth, and the other end of the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com