Circumferential retractable roof structure

A cover structure and hoop technology, applied to roofs, building components, building structures, etc., can solve problems such as lagging research on opening and closing roofs, and achieve the effects of overcoming numerous and messy rods, reasonable structure, and increasing the movement stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below with reference to accompanying drawing of description, the specific embodiment of the present invention is described in more detail:

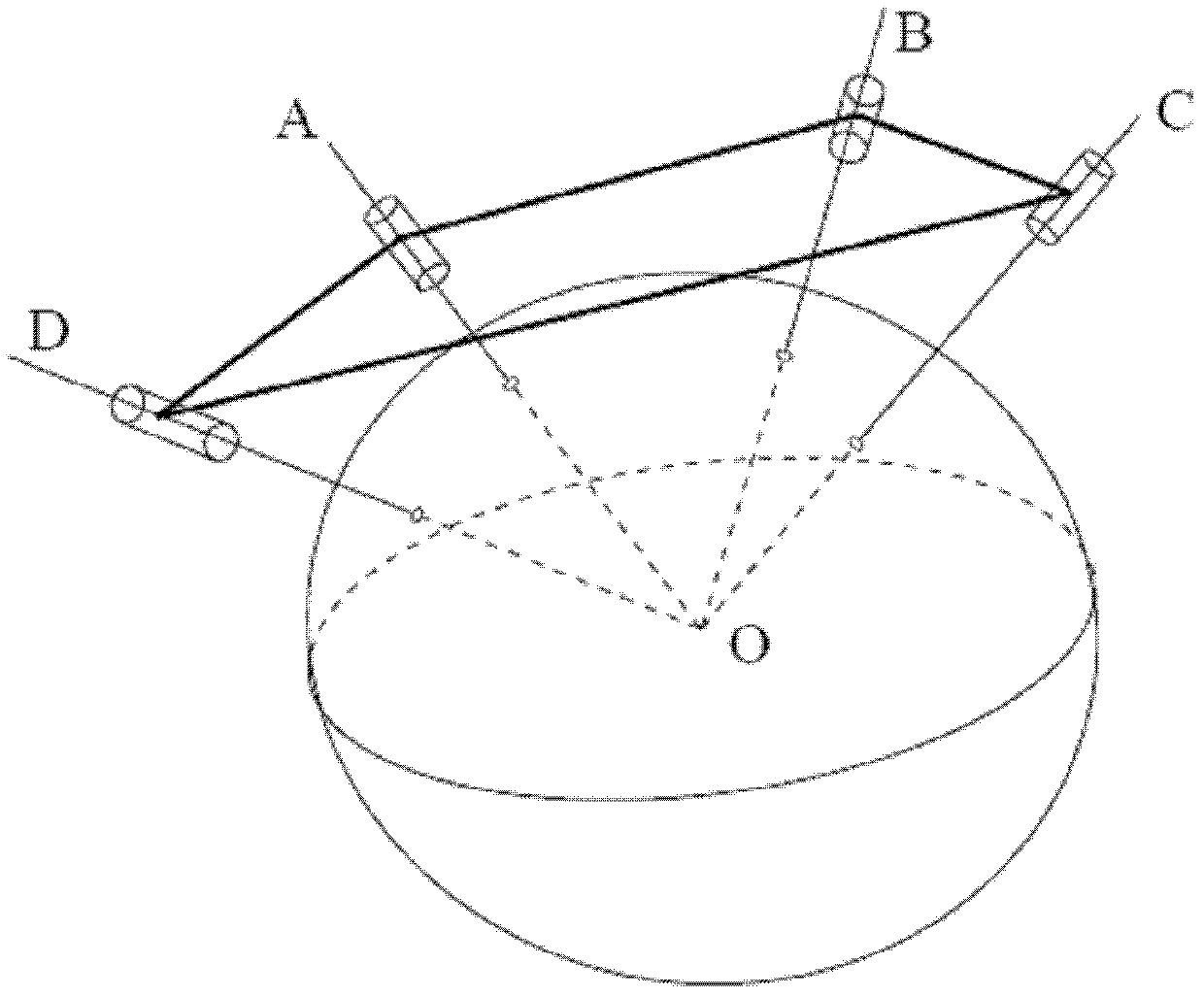

[0029] Such as figure 2 with image 3 As shown in the figure, a ring-opening roof structure is composed of a spherical four-plate mechanism composed of four flat plates connected to each other along the ring direction of the roof.

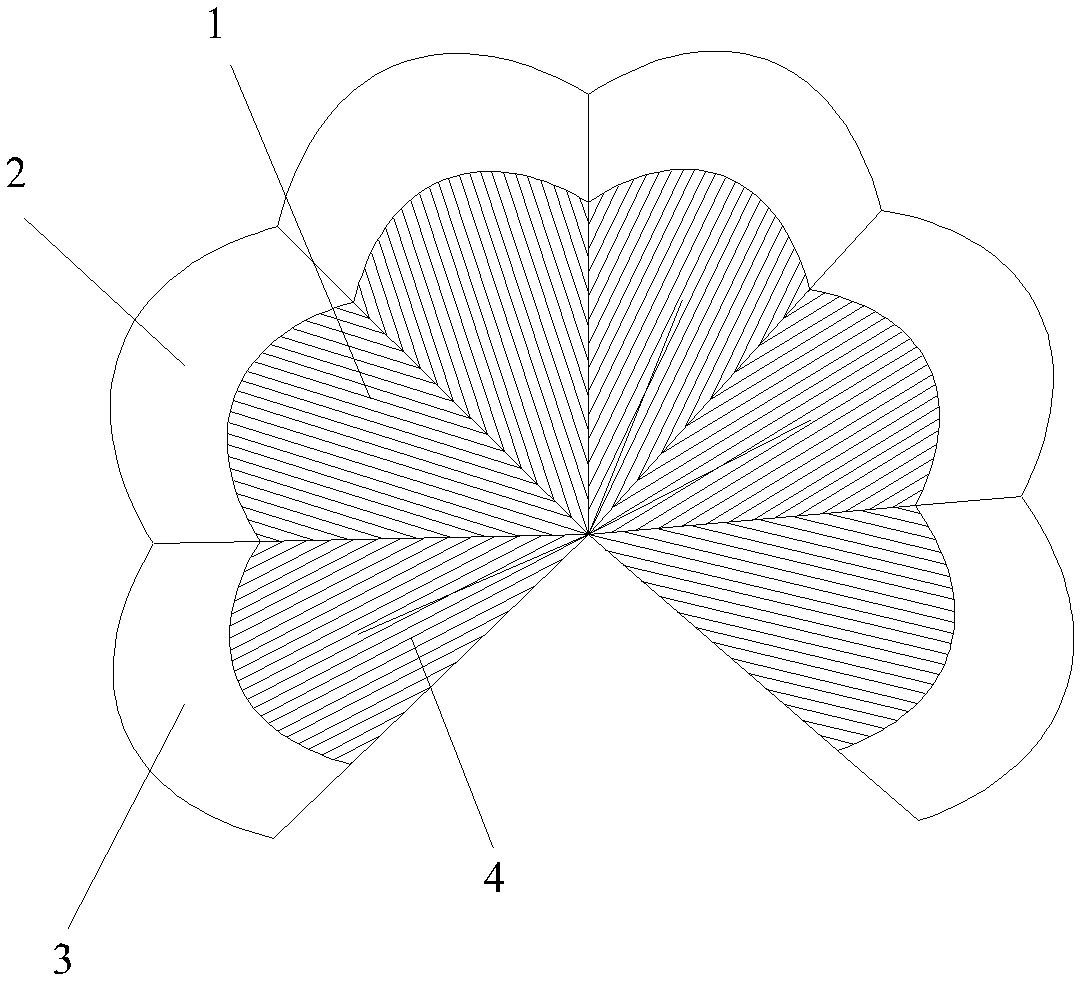

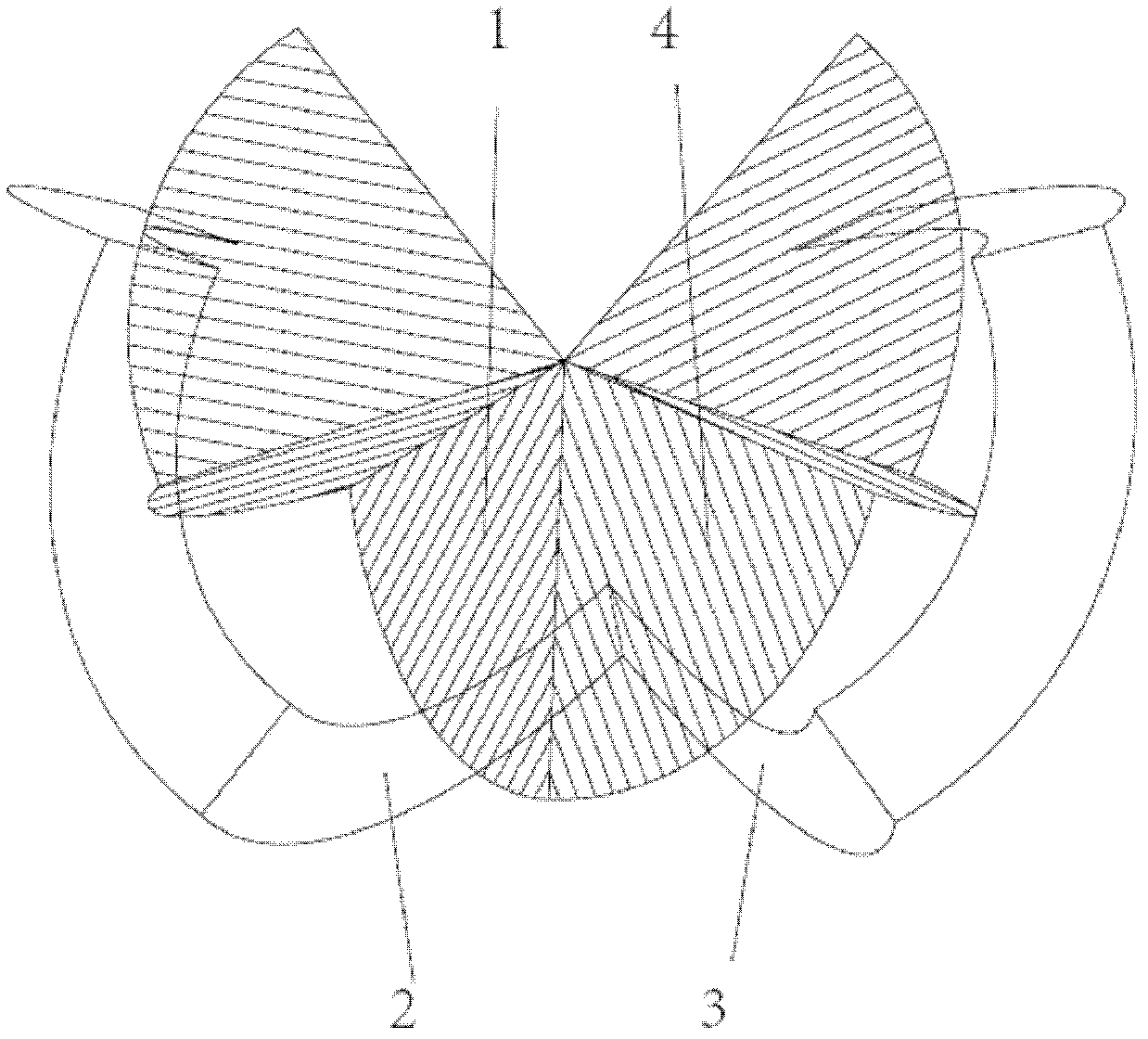

[0030] The spherical four-plate mechanism, such as Figure 4 As shown, it is composed of the first flat plate 1, the second flat plate 2, the third flat plate 3 and the fourth flat plate 4, and the first flat plate 1 and the second flat plate 2 are connected by a middle column hinge (as Figure 5 with 6 As shown), the second flat plate 2 and the third flat plate 3 are connected through their common side rolling hinge, the third flat plate 3 and the fourth flat plate 4 are connected through the middle column hinge, the fourth flat plate 4 and the first flat plate 1 are connected through the common si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com