Full-automatic shoulder belt sewing machine

A sewing machine, fully automatic technology, applied in the direction of sewing machine components, cloth feeding mechanism, sewing equipment, etc., can solve the problems of unguaranteed product quality, low work efficiency, and increased manual error rate, so as to save labor and improve The effect of production efficiency and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

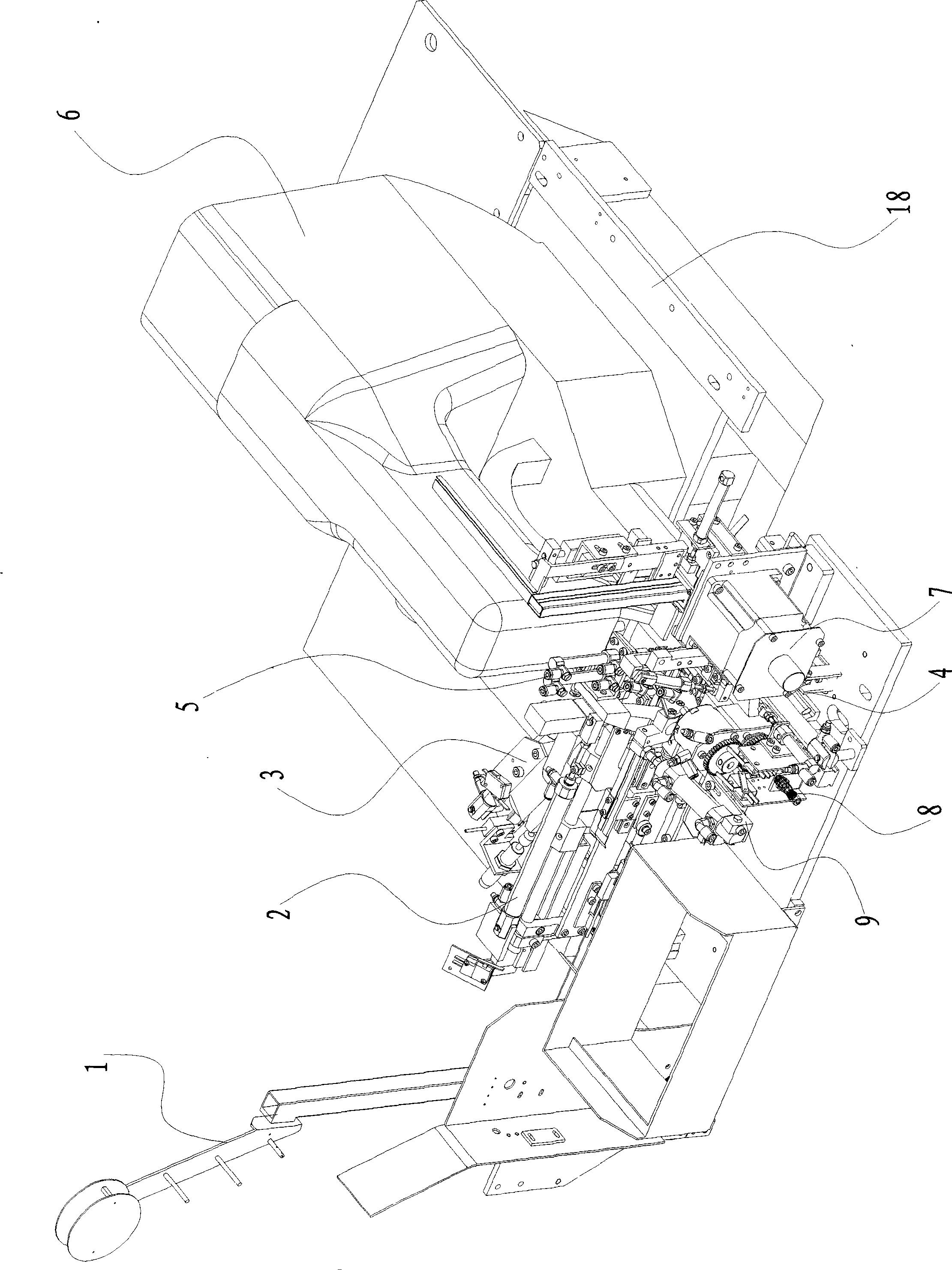

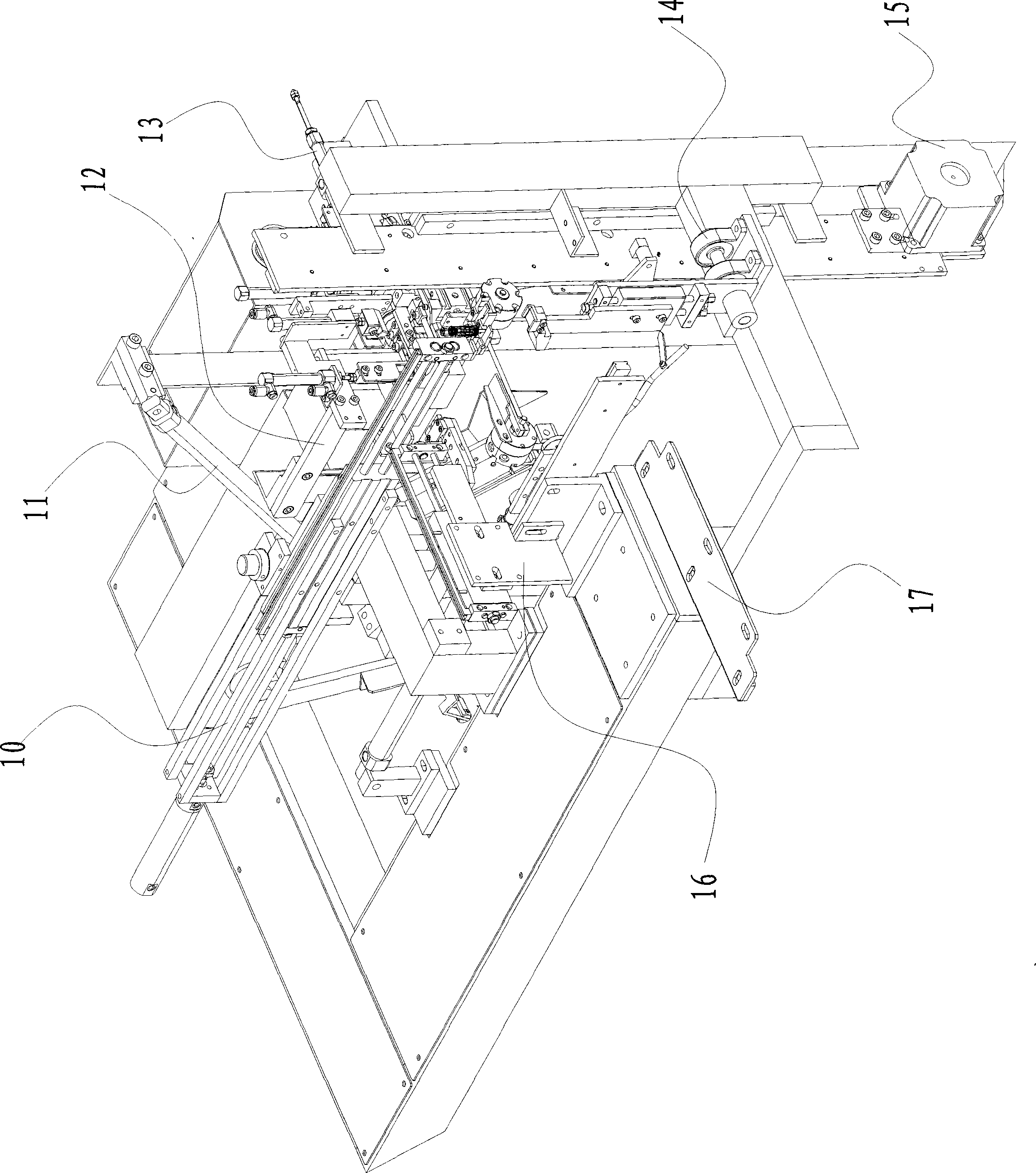

[0058] A full-automatic shoulder belt sewing machine, which is composed of a pre-process machine and a post-process machine; the pre-process machine and the post-process machine are spliced and fastened together through the connecting plate 18 of the pre-process machine and the connecting plate 17 of the post-process machine;

[0059] The pre-process machine is mainly composed of a belt feeding device 1, a belt pushing device 2, a belt cutting device 9, a device for sending 8 buckles 3, a device for sending 9 buckles or 0 buckles 4, a belt threading device 5, a rotating buckle turning device 8, a pull The belt device 7 and the sewing device 6 are composed; the belt pushing device 2 is connected with the belt feeding device 1; the belt threading device 5 is connected with the belt pulling device 7, the 8-buckle device 3, and the 9-buckle or 0-buckle device 4 .

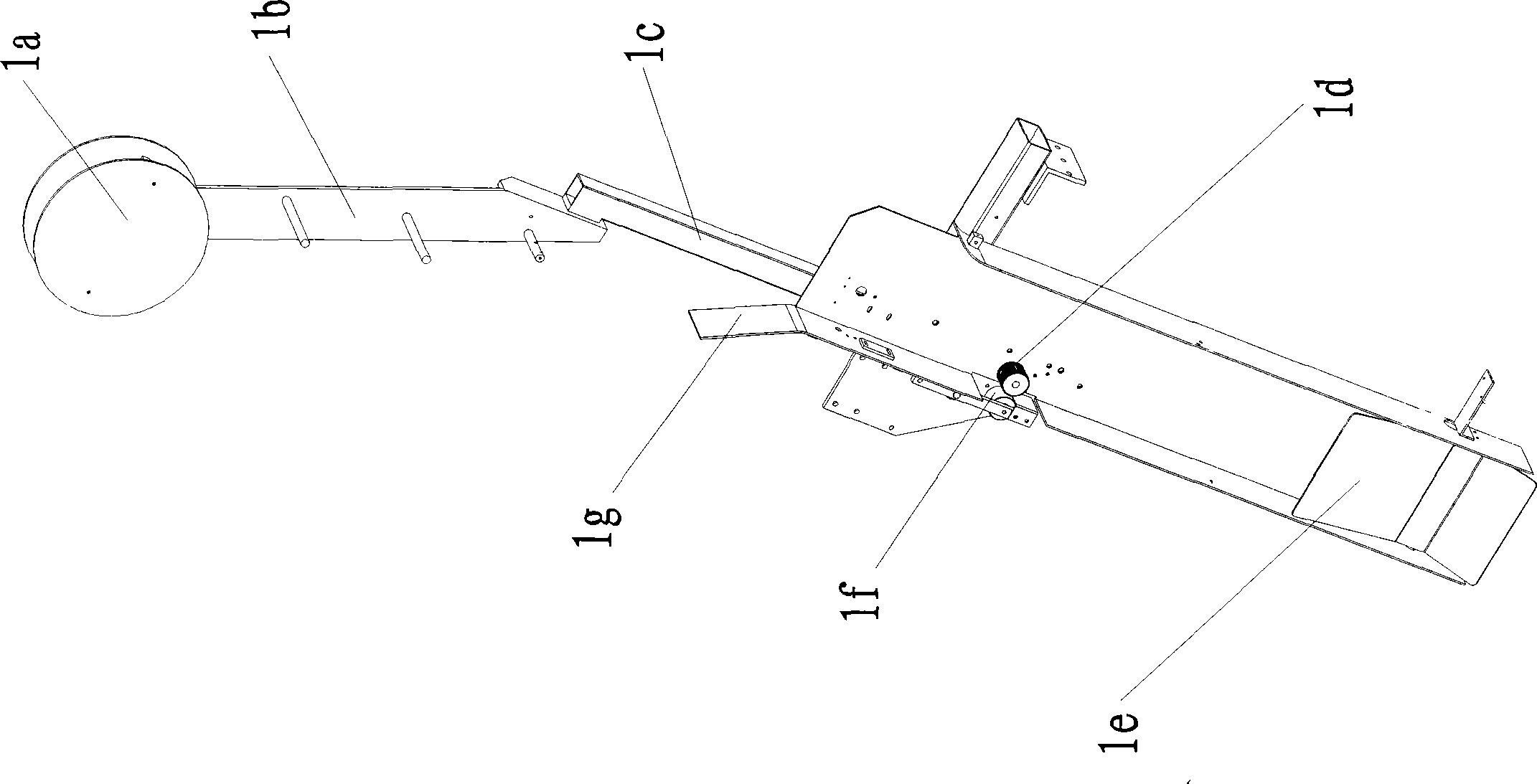

[0060] The belt feeding device 1 mainly includes: belt protection reel 1a, bracket 1b, support rod 1c, belt running...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com