Cam knitting mechanism with electromagnetic needle selecting function of computerized flat knitting machine

A triangular and electromagnetic technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of decreased knitting needle stability, affecting knitting quality, etc., and achieve the effect of reducing consumables, improving knitting quality, and knitting needles running smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

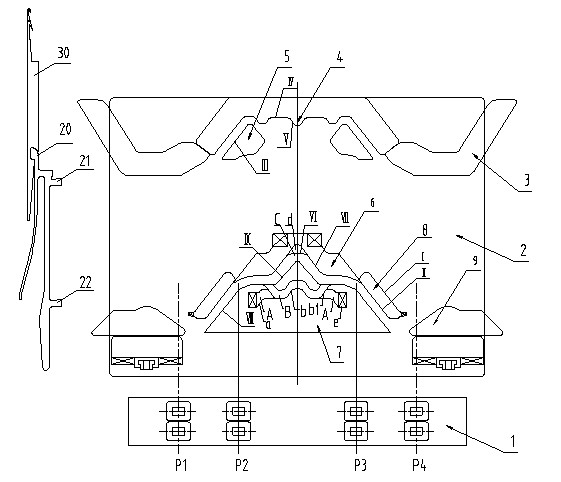

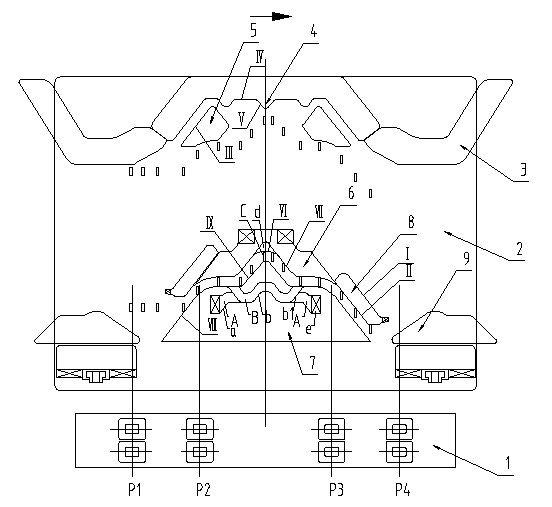

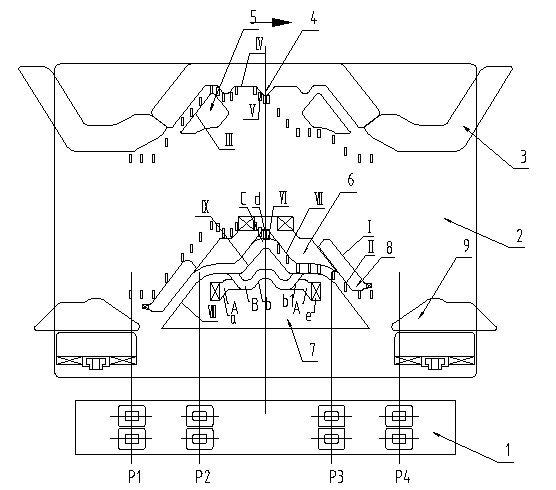

[0018] combine figure 1 , the electromagnetic needle selection cam knitting mechanism of the flat knitting machine includes an electromagnetic needle selector 1, a cam bottom plate 2, and a knitting cam. Each knitting unit 3 is provided with four electromagnetic needle selection positions, which are P1, P2, P3, and P4 needle selection positions from left to right. Among them, the P1 needle selection position is symmetrical to the P4 needle selection position, and the P2 needle selection position is symmetrical to the P4 needle selection position. P3 needle selection is symmetrical. The knitting cams include the loop transfer and blocking cam 4 placed on the upper part of the knitting unit, the loop transfer finishing cam 5 symmetrically arranged below the loop transfer and blocking cam 4, the eyebrow triangle located under the loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com