Method for separating and purifying polycarbonate glue solution

A polycarbonate, separation and purification technology, applied in the chemical industry, can solve the problems of material waste, material loss, and many dynamic equipment, and achieve the effects of saving material use, simplifying operations, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

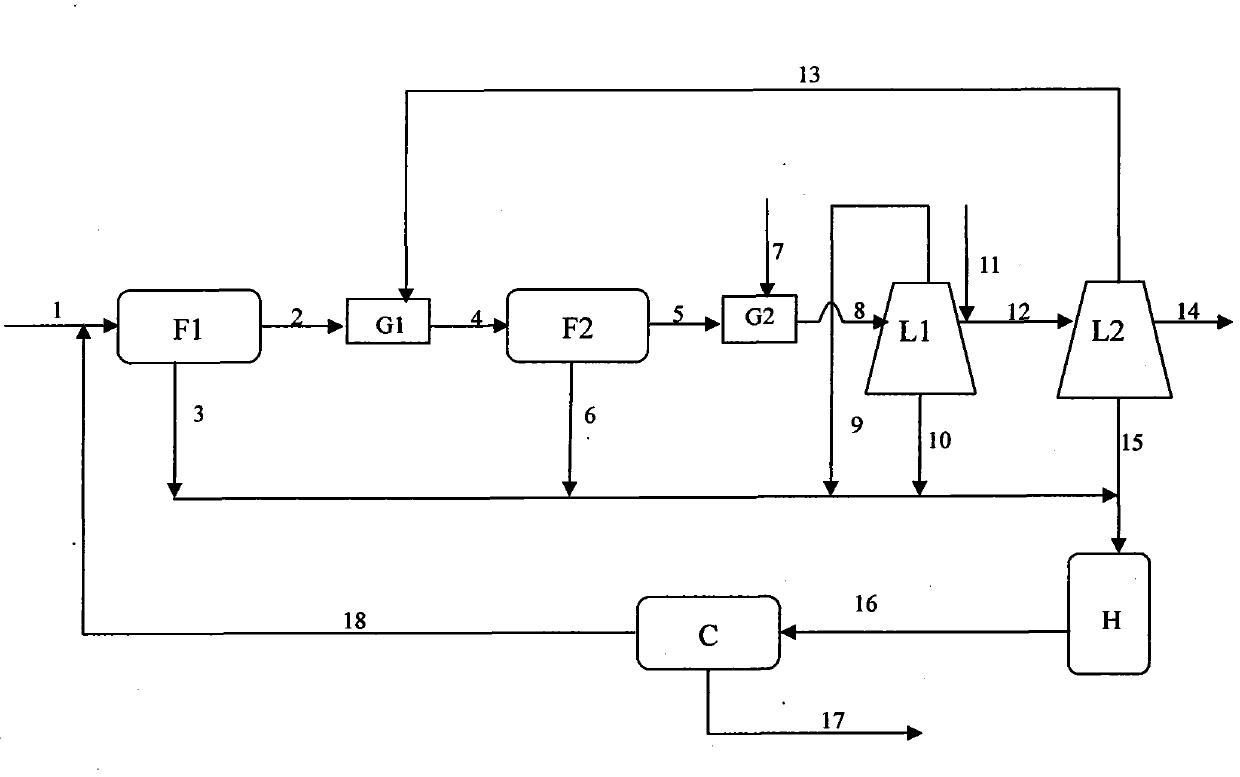

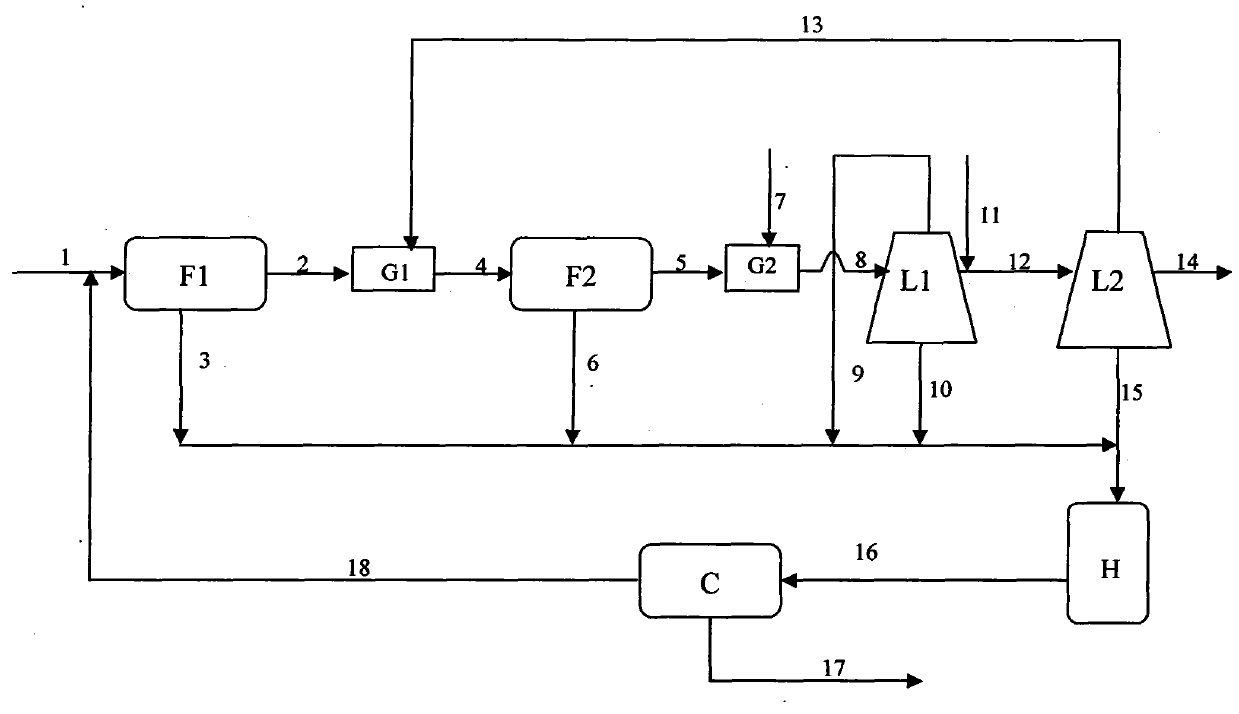

[0032]The product prepared by the phosgene interfacial polycondensation method, wherein the polycarbonate weight average molecular weight is 30000, the molecular weight distribution is 2.01, the organic phase composed of dichloromethane and polycarbonate accounts for about 62% of the total volume, and the polycarbonate in the organic phase The content of polycarbonate is 14%, and sodium chloride content is 15.5% in the aqueous phase, and sodium carbonate content is 2%, and the step of separation and purification polycarbonate glue solution is as follows, see figure 1 :

[0033] a. The above-mentioned product, material 1, is continuously pumped to the inclined plate separator F1 for the first precipitation separation, the temperature is controlled at 10-20°C, the flow rate is controlled at 2000kg / h, and the inlet pressure of the inclined plate separator F1 is 0.2Mpa, the residence time is 10-20 minutes, and the organic phase 2 and the water phase 3 are separated by precipitatio...

Embodiment 2

[0046] The product prepared by the phosgene interfacial polycondensation method, wherein the polycarbonate weight average molecular weight is 100000, the molecular weight distribution is 2.06, the organic phase composed of dichloromethane and polycarbonate accounts for about 60% of the total volume, and the polycarbonate in the organic phase The content of polycarbonate is 10%, and sodium chloride content is 14% in the aqueous phase, and sodium carbonate content is 1.5%, and the step of separation and purification polycarbonate glue solution is as follows, see figure 1 :

[0047] a. The above-mentioned product, namely material 1, is continuously pumped to the inclined plate separator F1 for the first precipitation separation, the temperature is controlled at 20-30°C, the flow rate is controlled at 1500kg / h, and the inlet pressure of the inclined plate separator F1 is 0.2Mpa, the residence time is 20-40 minutes, and the organic phase 2 and the water phase 3 are separated by pre...

Embodiment 3

[0058] Example 3, see figure 1 :

[0059] The present invention can not only separate and purify the product after interfacial polycondensation of phosgene, but also can separate the mixed liquid composed of polycarbonate, dichloromethane and process water. This mixed liquid is generally formed during the production process when waste materials are processed. This mixture works better.

[0060] Fully mix the polycarbonate glue with a weight average molecular weight of 15000, a molecular weight distribution of 2.1, and a resin concentration of 20% with process water, wherein the volume ratio of the aqueous phase to the organic phase is 0.6. After mixing fully, the polycarbonate The water content in the glue is 2%, and the triethylamine content is 0.06%. The mixed solution is delivered to the inclined plate separator F1 by a pump at a flow rate of 3000kg / h, and then enters the process flow described in the present invention successively. The processing water flow rate of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com