Yarn winding machine

A yarn winding machine and yarn technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems that the yarn can not be pushed out, there is no record guide frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

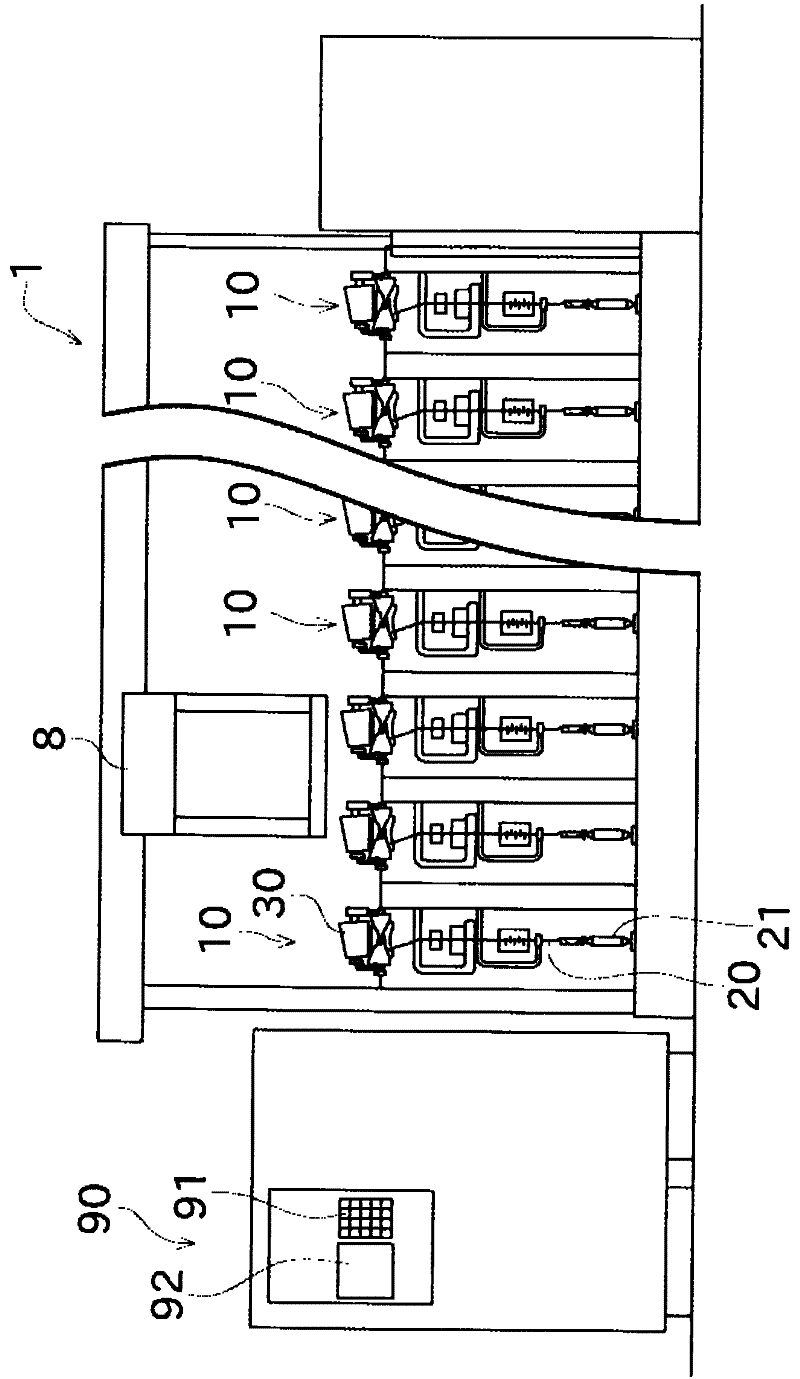

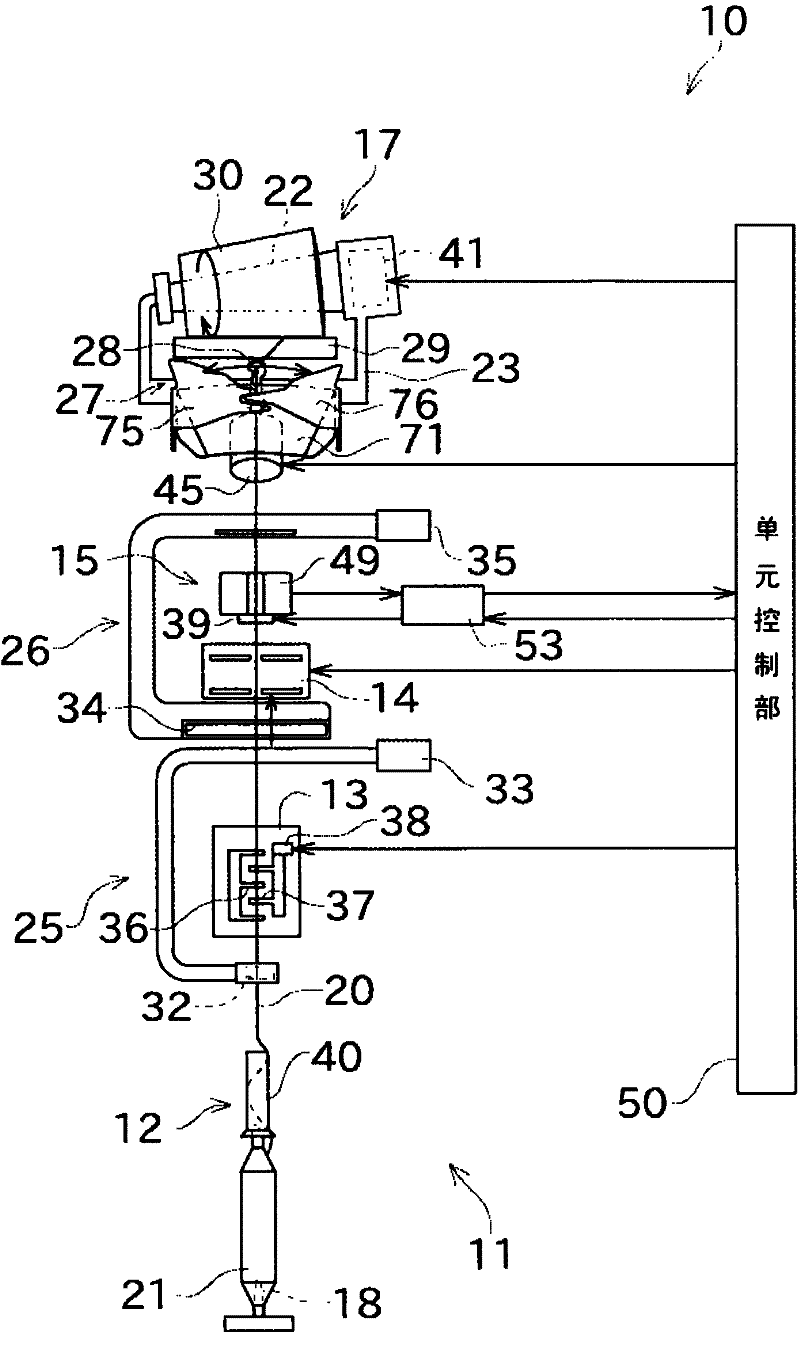

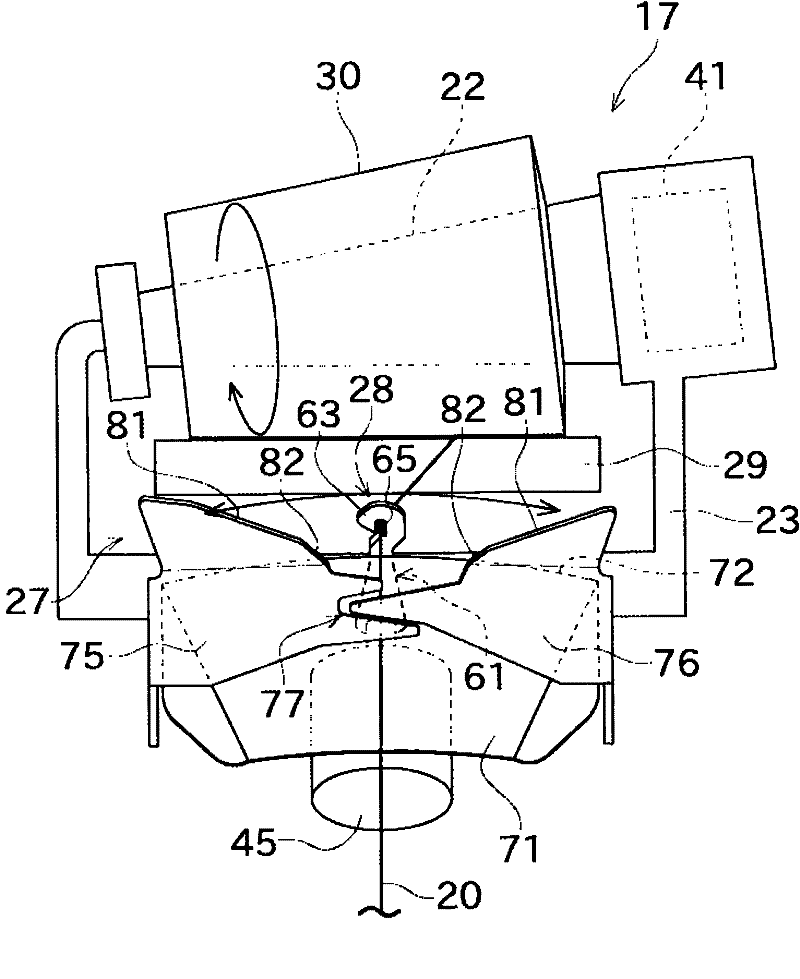

[0037] Next, embodiments of the invention will be described. First, refer to figure 1 The overall configuration of the automatic winder 1 of this embodiment will be described. figure 1 It is a front view of the automatic winder 1 according to one embodiment of the present invention. In addition, in this specification, "upstream" and "downstream" mean upstream and downstream in the moving direction of the yarn at the time of yarn winding. That is, if figure 2 etc., in this embodiment, the yarn 20 unwound from the yarn supplying bobbin 21 in the bobbin setting part 18 is wound by the winding part 17, so the bobbin setting part 18 side becomes upstream, and the winding part 17 side become downstream.

[0038] Such as figure 1 As shown, an automatic winder (yarn winder) 1 is mainly composed of a plurality of winder units (winder units) 10 arranged in parallel, an automatic doffing device 8, and a machine control device. (machine control device)90.

[0039] Each winder unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com