Jacket applicable to horizontal glass lining equipment

A glass-lined and jacket technology is applied in the field of jackets suitable for horizontal glass-lined equipment, which can solve the problems of uneven temperature of materials, safety risks, undetectable quality of longitudinal seam welding, etc. The effect of material temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technology will be further described below in conjunction with the accompanying drawings and embodiments.

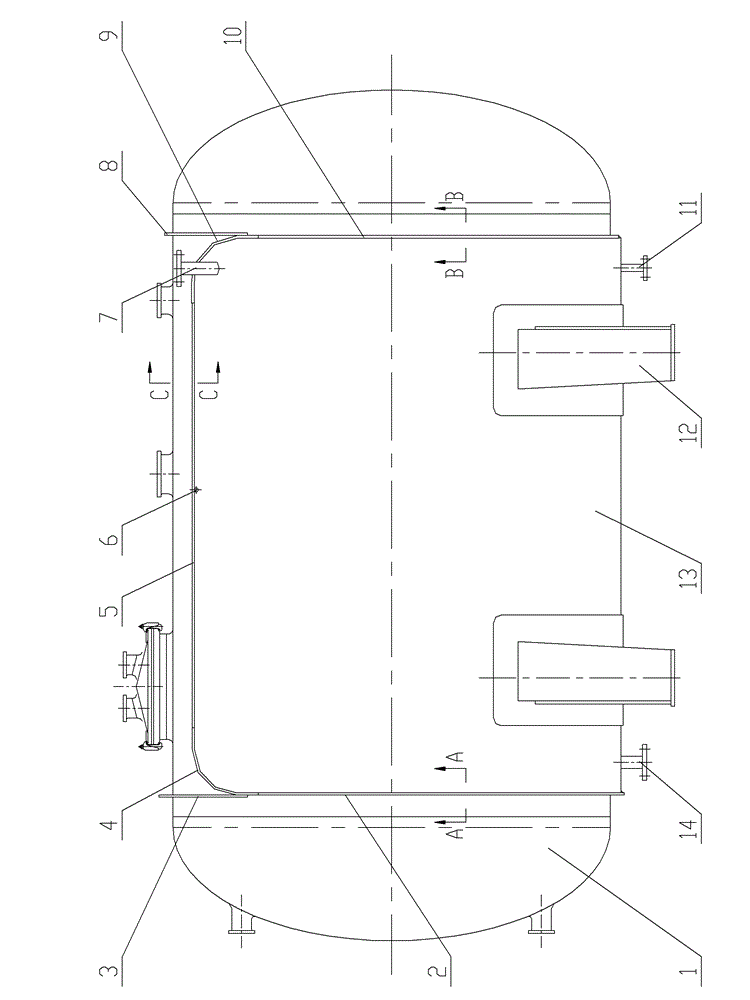

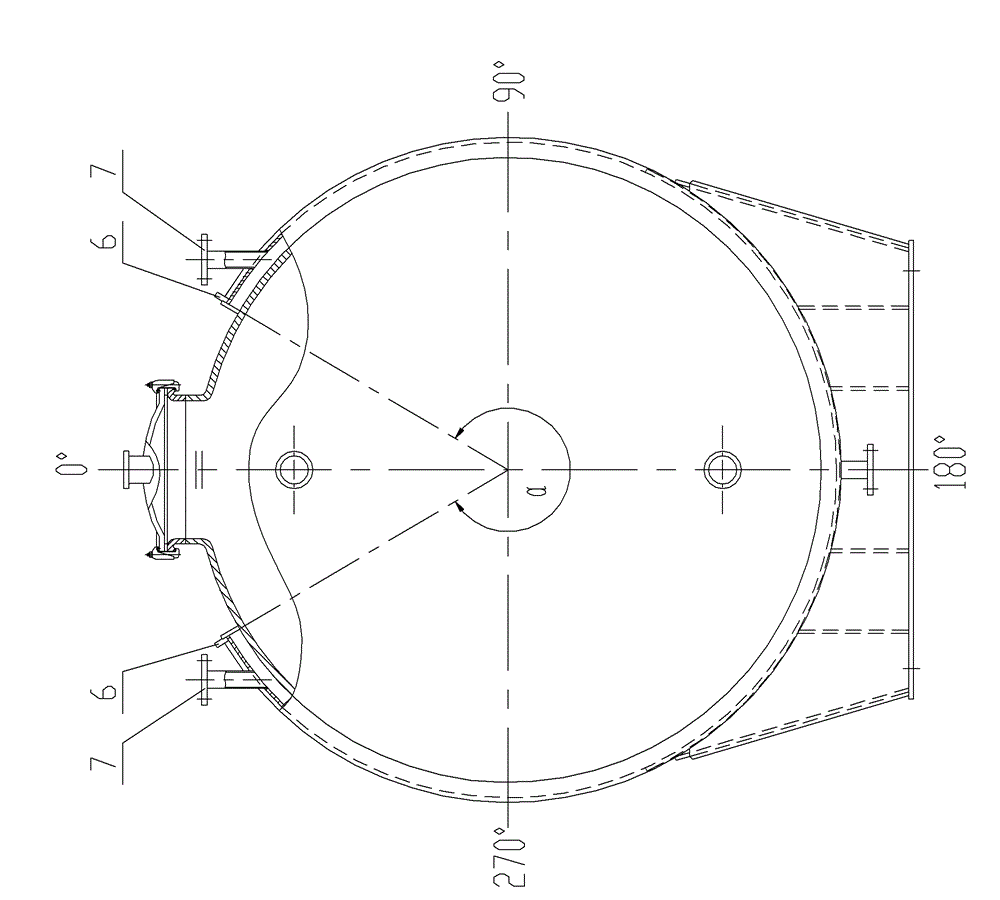

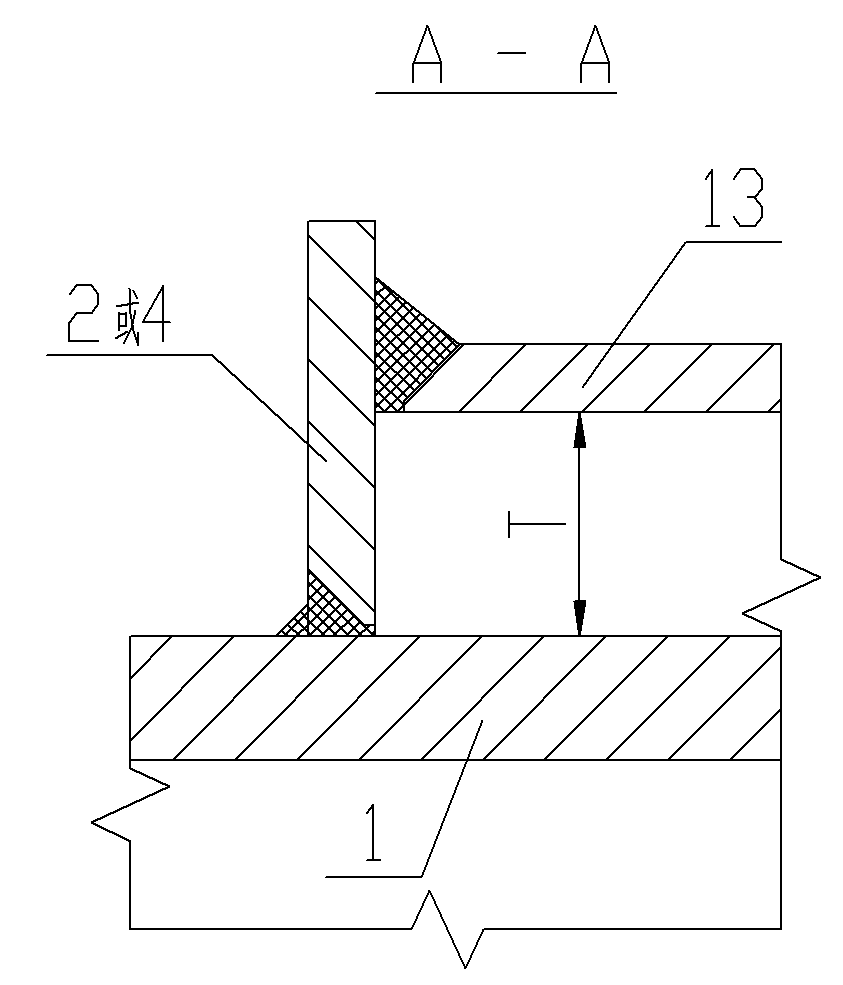

[0021] In the embodiment shown in the figure, a new type of high-efficiency jacket suitable for horizontal glass-lined equipment, the left annular sealing plate, the anti-deformation connecting plate, the left R-shaped sealing plate, the straight sealing plate, and the right anti-deformation connection Plate, right R-shaped sealing plate, right annular sealing plate and glass-lined tank body are welded and fired, and the jacket cylinder body and exhaust port, jacket medium outlet, sewage outlet, and jacket medium inlet are assembled from the right after welding. The side of the ring seal plate (or from the side of the left ring seal plate) is inserted into the outside of the glass-lined tank and welded with the left ring seal plate, left R-shaped seal plate, straight shape seal plate, right R-shaped seal plate, and right ring seal plate Form a "C"-shaped jacke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com