Electric dehydrating oil-water separator with constant liquid level

An oil-water separator and electric dehydration technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of affecting the separation effect, instability, and the oil-water interface of the separator liquid level fluctuation, so as to ensure the separation effect. , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

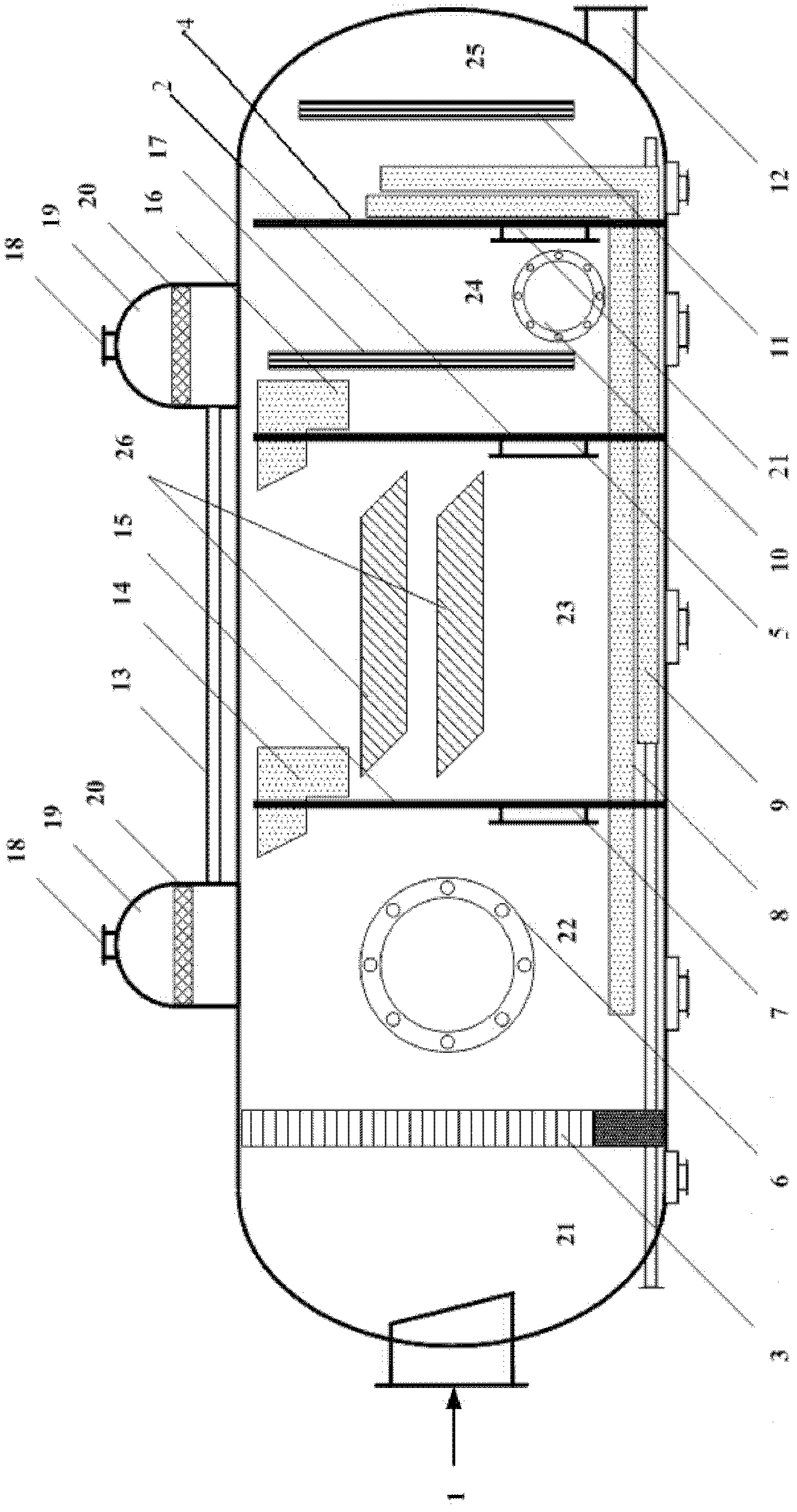

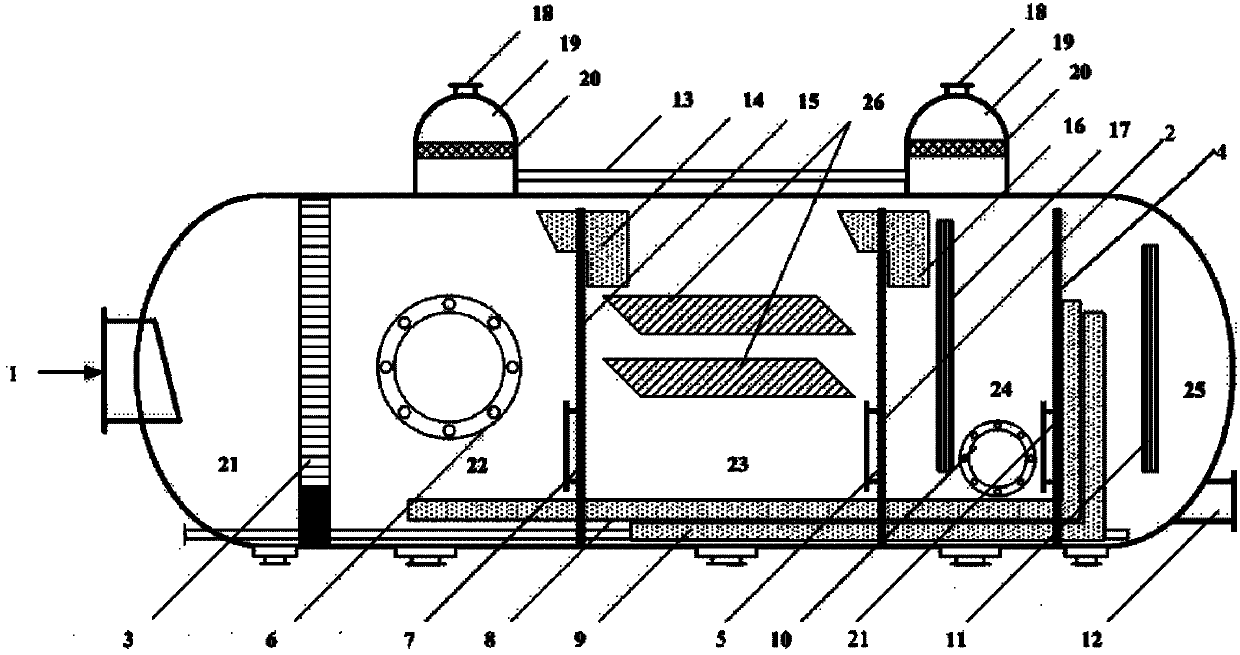

[0022] Such as figure 1 As shown, the present invention provides a kind of electric deoiler water separator with constant liquid level, comprises: electric dehydration separation chamber 23, is provided with the electric dehydration electrode plate 26 that is used to form electric field in it; The electric dehydration separation chamber 23 is adjacent, and the electric dehydration separation chamber 23 communicates with the rear chamber 24 through the first overflow channel 16, and the first overflow channel 16 is used to transfer the The oil separated by the dehydration separation chamber 23 is introduced into the rear chamber 24; the sewage discharge chamber 25 communicates with the electric dehydration separation chamber 23 through the first drainage channel 9, and the first drainage pipe 9 is used to The water separated by the electric dehydration separation chamber 23 is introduced into the sewage discharge chamber 25, the first drainage pipe has a horizontal section and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com