Squirrel-cage Rotor And Method For Producing Such A Squirrel-cage Rotor

A technology for short-circuiting rotors and rotor shafts, which is applied in the manufacture of squirrel-cage rotors, motor generators, electrical components, etc. The effect of balancing and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

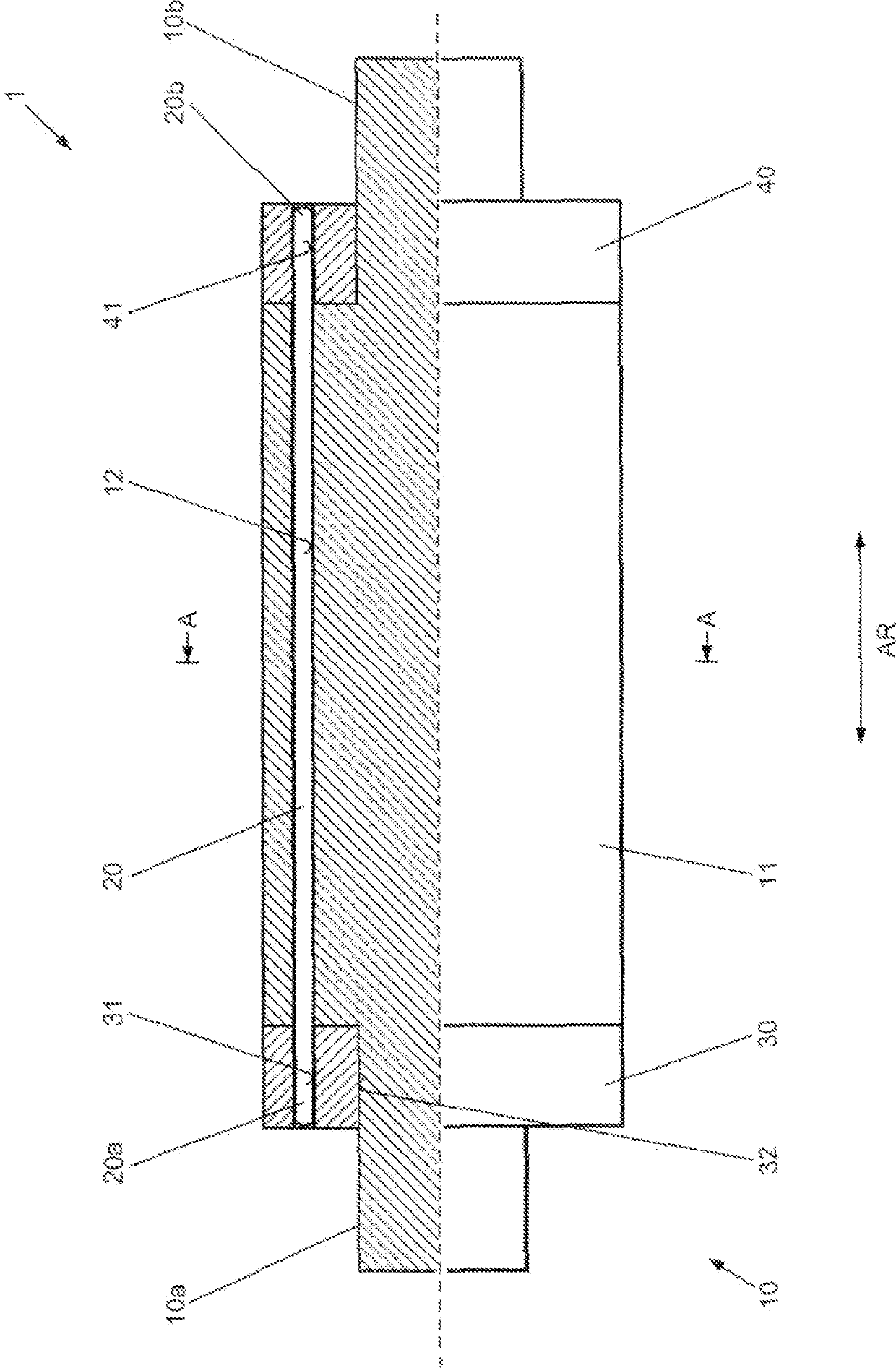

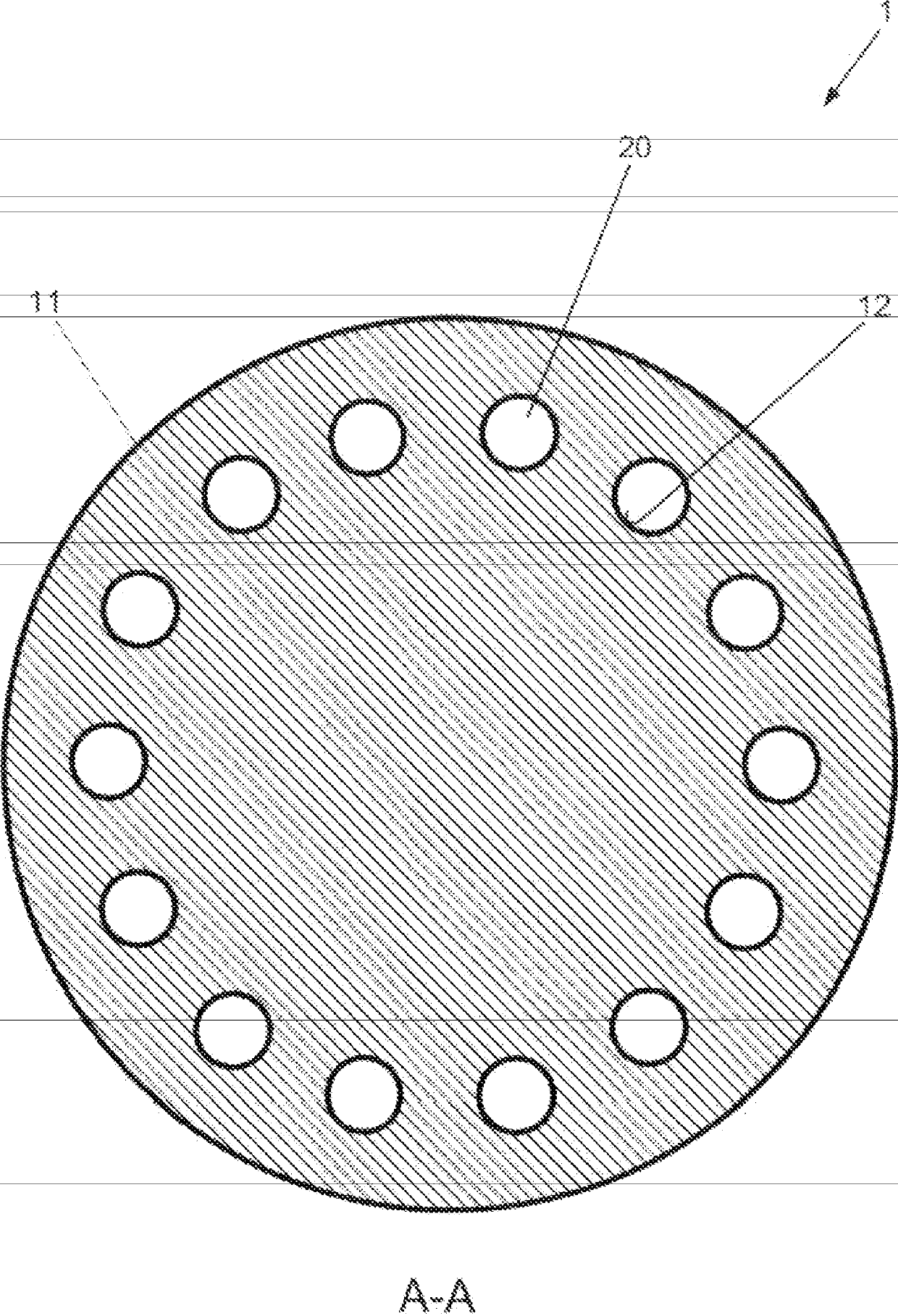

[0041] as in figure 1 and figure 2 As shown in , a short-circuit rotor 1 (not shown in full) for an electric motor according to the invention has a rotor shaft 10 formed of ferromagnetic material (which has a cylindrical shaft molded thereon in one piece). A solid rotor section 11 in the form of a diameter enlargement (Durchmesservergroesserung), a plurality of electrically conductive rod elements 20 (which have an annular cross-section with a constant diameter) and in the form of two corresponding one-piece end rings Two electrically conductive end elements 30 and 40 .

[0042] The solid rotor section 11 has a plurality of through-channels 12 extending distributed around the circumference of the rotor shaft 11 in the axial direction AR of the rotor shaft 10 .

[0043] A rod element 20 is accommodated in each of the through channels 12 such that the respective rod element 20 extends through the solid rotor section 11 in the axial direction AR of the rotor shaft 10 , wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com