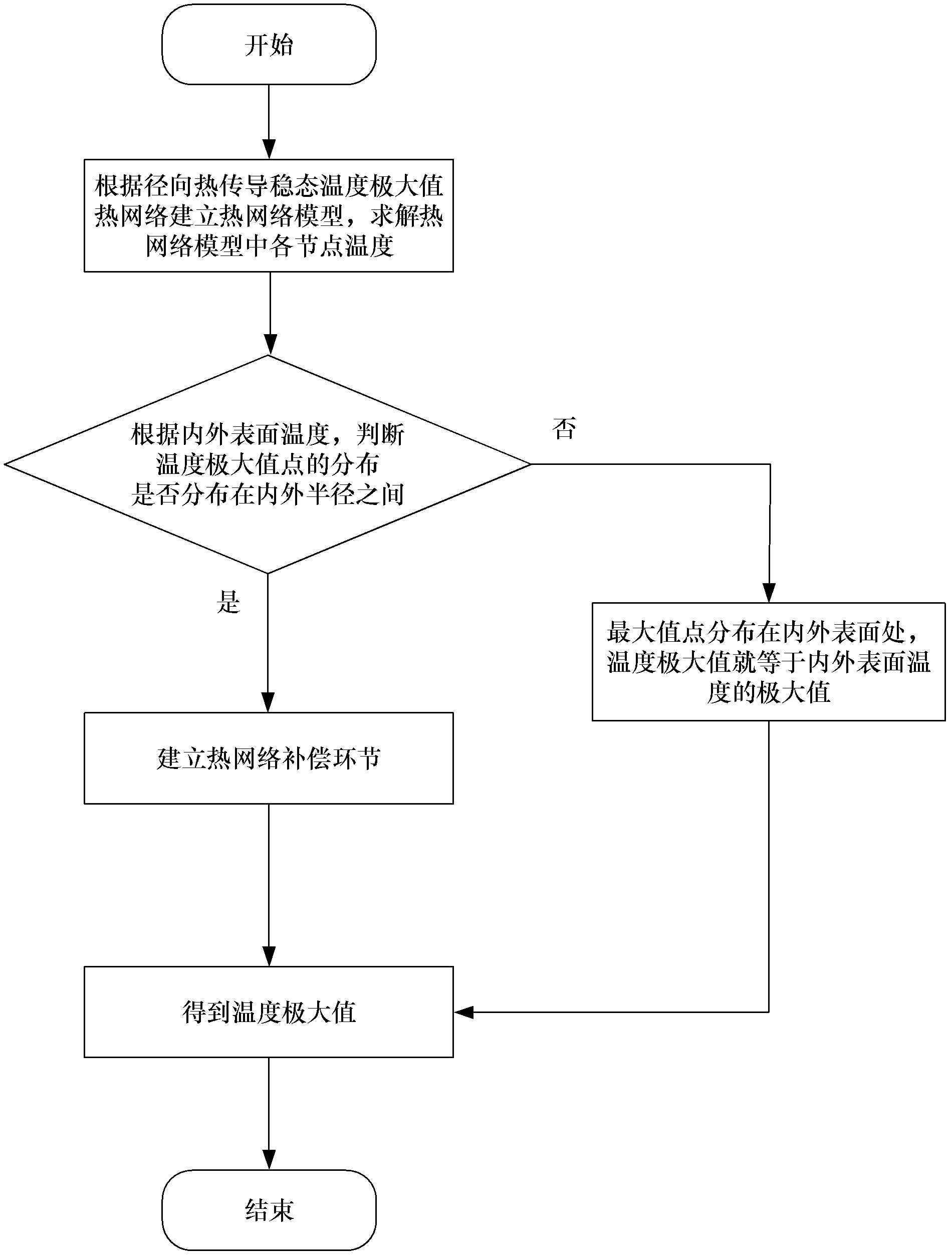

Heat-network modeling method for determining maximum value of steady-state temperature of heat conduction in radial direction

A modeling method and technology of thermal network model, which is applied in the field of thermal network modeling to determine the maximum value of the steady-state temperature of radial heat conduction, and can solve the problem of inability to solve the maximum value of the steady-state temperature of the radial heat conduction of a circular wall cylinder. , to achieve the effect of intuitive modeling and fast solution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

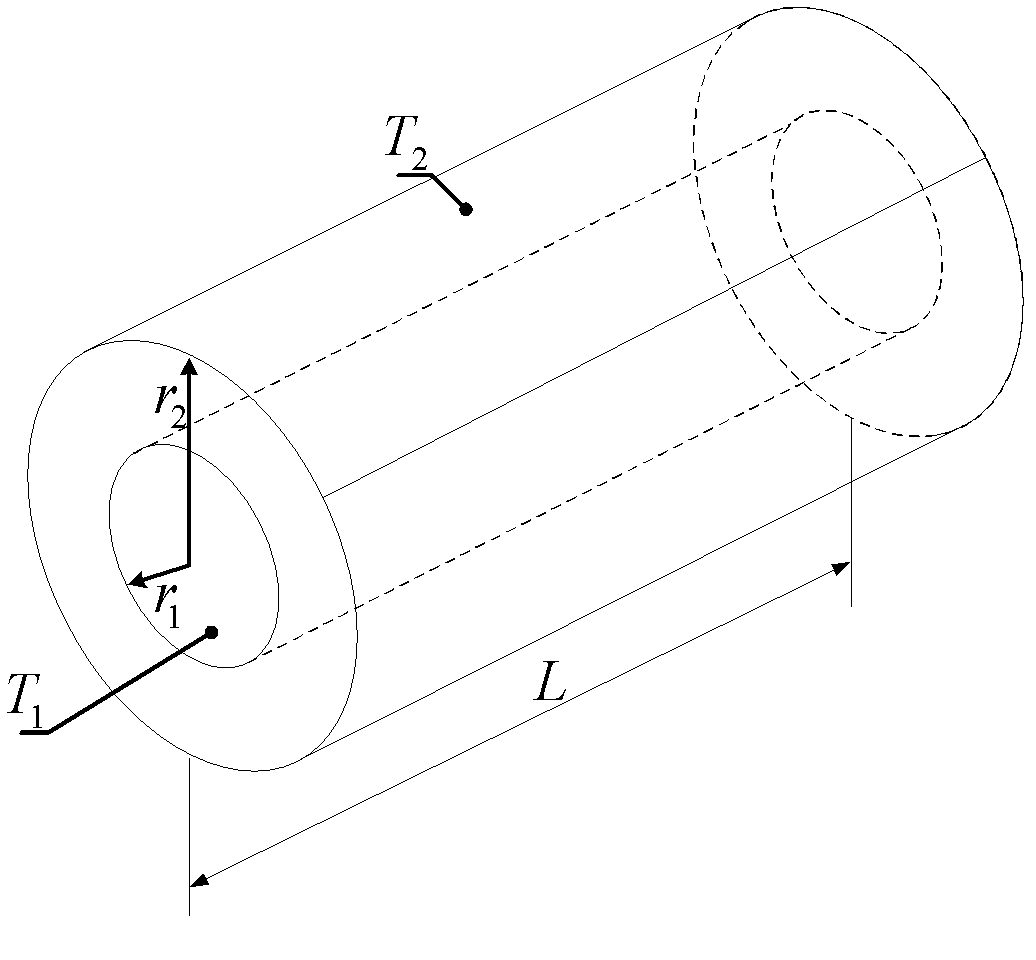

[0099] Taking the stator core and stator teeth in the motor structure as objects, using the thermal network modeling method of the radial heat conduction steady-state temperature maximum value provided by the present invention, and using the mellor modeling method to establish their thermal network models respectively, and The solution results of the respective models are compared with the guideline results of the ANSYS software to verify the correctness of the model established using the modeling method provided by the present invention, and then prove the practicability and effectiveness of the modeling method provided by the present invention. The structure of the motor stator iron core and the stator teeth as an embodiment is as follows: Figure 6 The values of the parameters are shown in Table 1.

[0100] Table 1 Motor stator core and tooth parameters used for modeling

[0101] parameters

value

unit

Inner diameter of stator core r 1_iron

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com