Large-capacity multi-functional optical fiber distribution box

A fiber optic distribution box and multi-functional technology, applied in the direction of fiber mechanical structure, can solve the problems of increasing the cost of network engineering construction, management and maintenance, etc., and achieve the effect of clear area division, convenient installation and disassembly, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

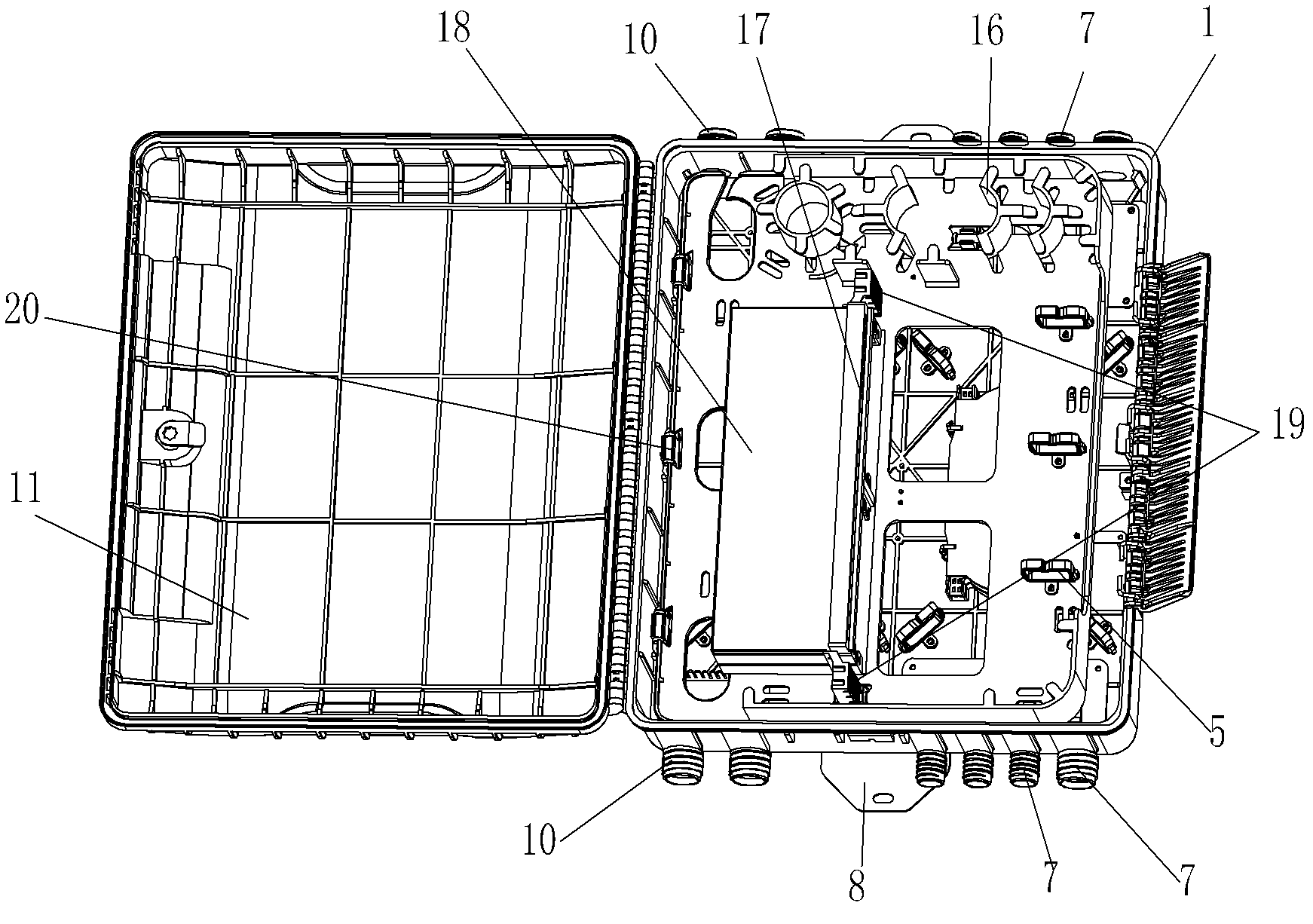

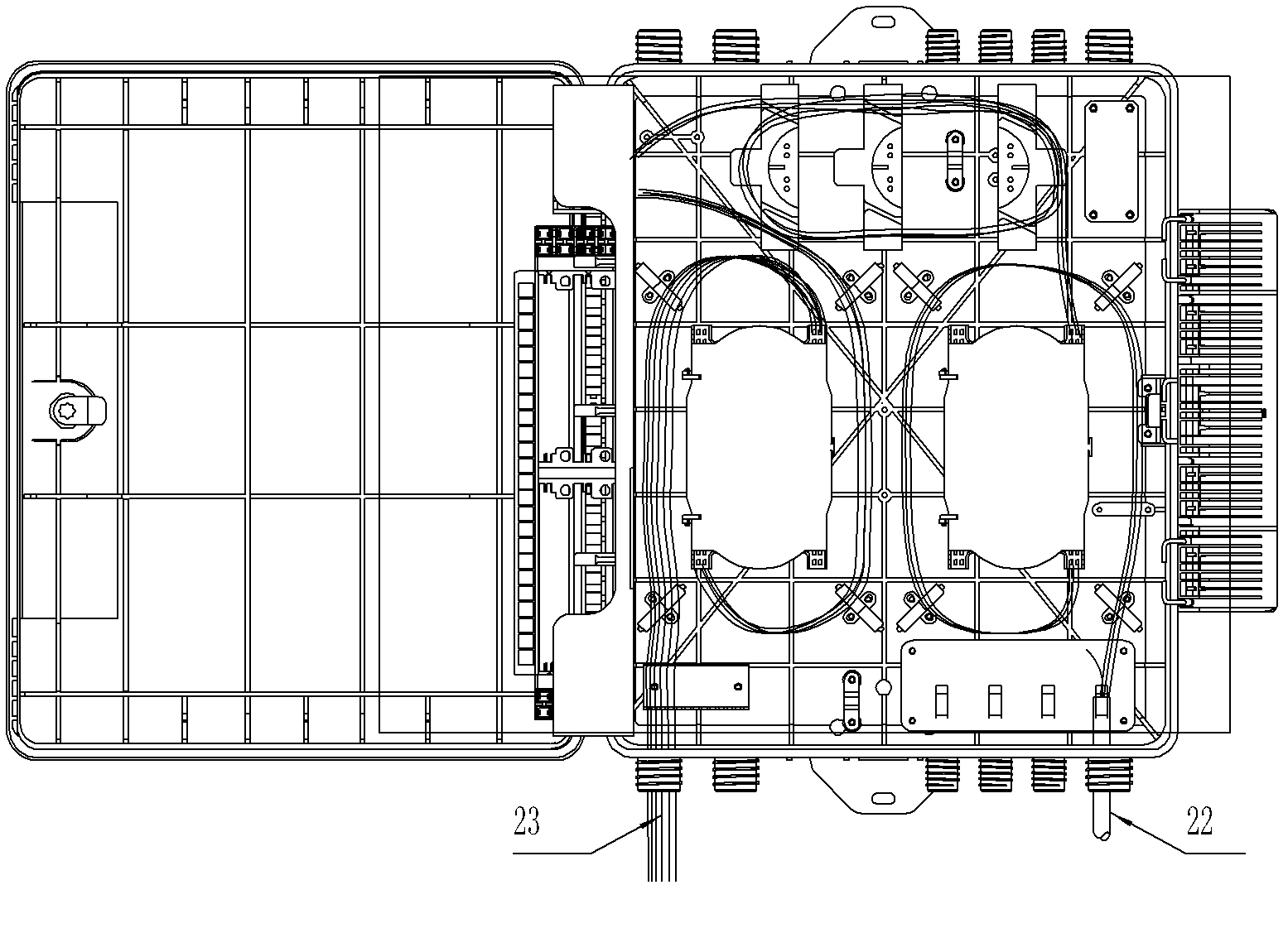

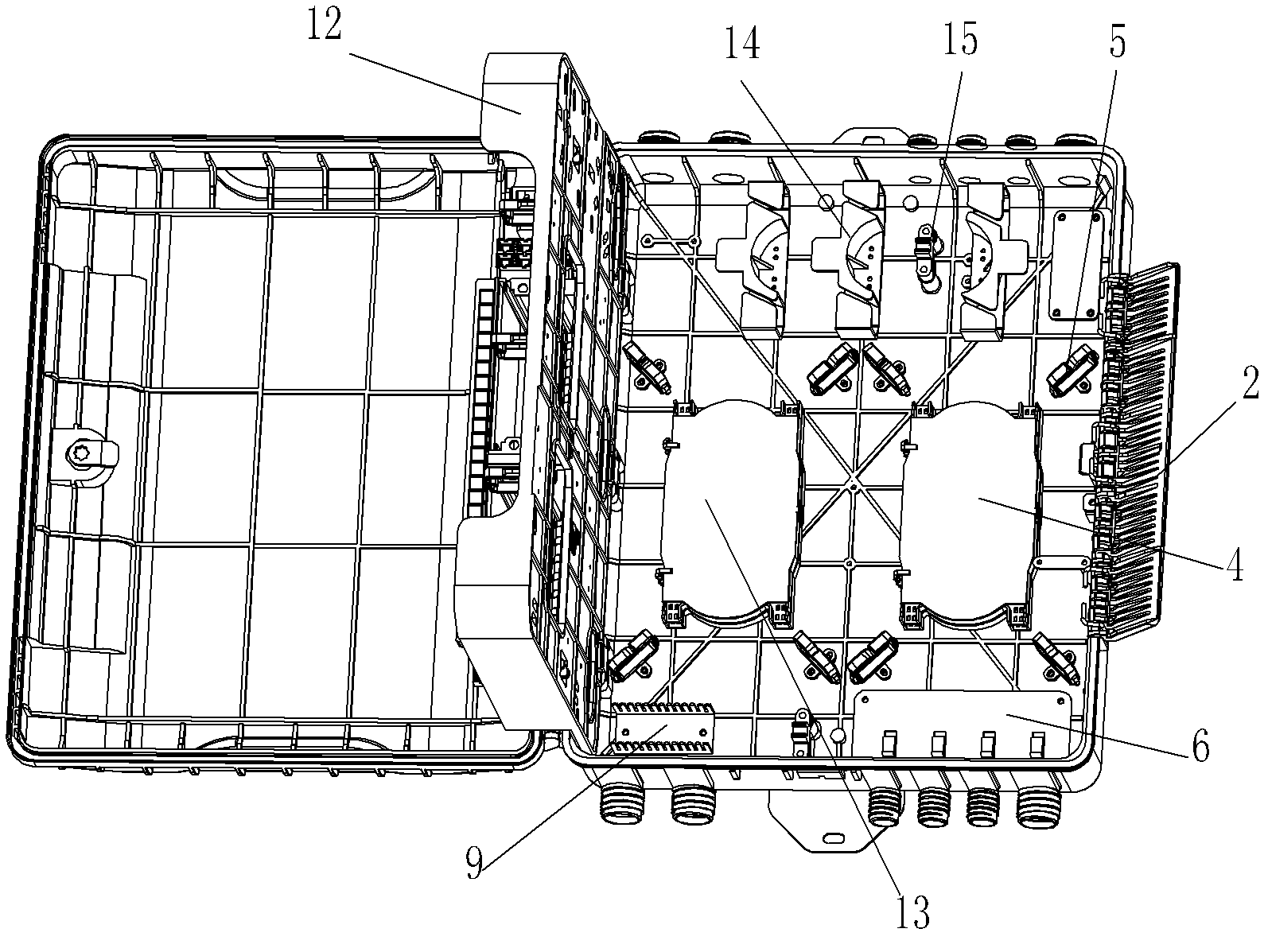

[0023] Such as figure 2 As shown, the large-capacity multifunctional optical fiber distribution box of the present invention includes a box body 1 with a cavity and a box door 11 installed on the box body. A main rotating plate 12 for separating the space of the box into inner and outer layers is hinged in the box through a buckle hinge shaft 20 (conventional parts), and the main rotating plate is fixed by a rotating plate arranged on the bottom plate of the box. Buckle 15 is fixed. The box walls on the upper and lower sides of the box body are respectively made with four optical cable inlet and outlet holes 7 (the optical cable inlet and outlet holes on the upper and lower side walls are arranged symmetrically) and two leather cable outlet holes 10 (direction refers to figure 2 ). The bottom plate of the box is provided with the main splicing tray 4 (a conventional component for optical fiber thermal fusion) and the wiring splicing tray 13 (the two splicing trays are loca...

Embodiment 2

[0030] The structure of embodiment 2 is different from embodiment 1 in that: the optical splitter mounting frame 18 on the main rotating plate is replaced with an adapter mounting seat plate 21 . Such as Figure 5 As shown, two adapter seat plates 21 (conventional structure) for installing FC-type and SC-type adapters are installed on the side of the main rotating plate close to the box door, and three transition wire rings 5 are respectively arranged on the left and right sides.

[0031] This embodiment 2 is mainly used as an end-type optical fiber distribution box , It works as Figure 7 and Figure 8 Shown:

[0032] The fiber routing of the end-type optical fiber distribution box is the same as that of the optical fiber distribution box. The left side of the adapter is terminated on the adapter through the transition line ring, and the cable pigtail is terminated on the right side at the same time. After being accommodated in the pigtail receiving area 16 of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com