High pressure regulating valve

A high-pressure regulating valve and valve body technology, which is applied in the field of high-pressure regulating valves, can solve problems such as inability to accurately support the armature, inability to adjust system damping, etc., and achieve the effect of improving reliability and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

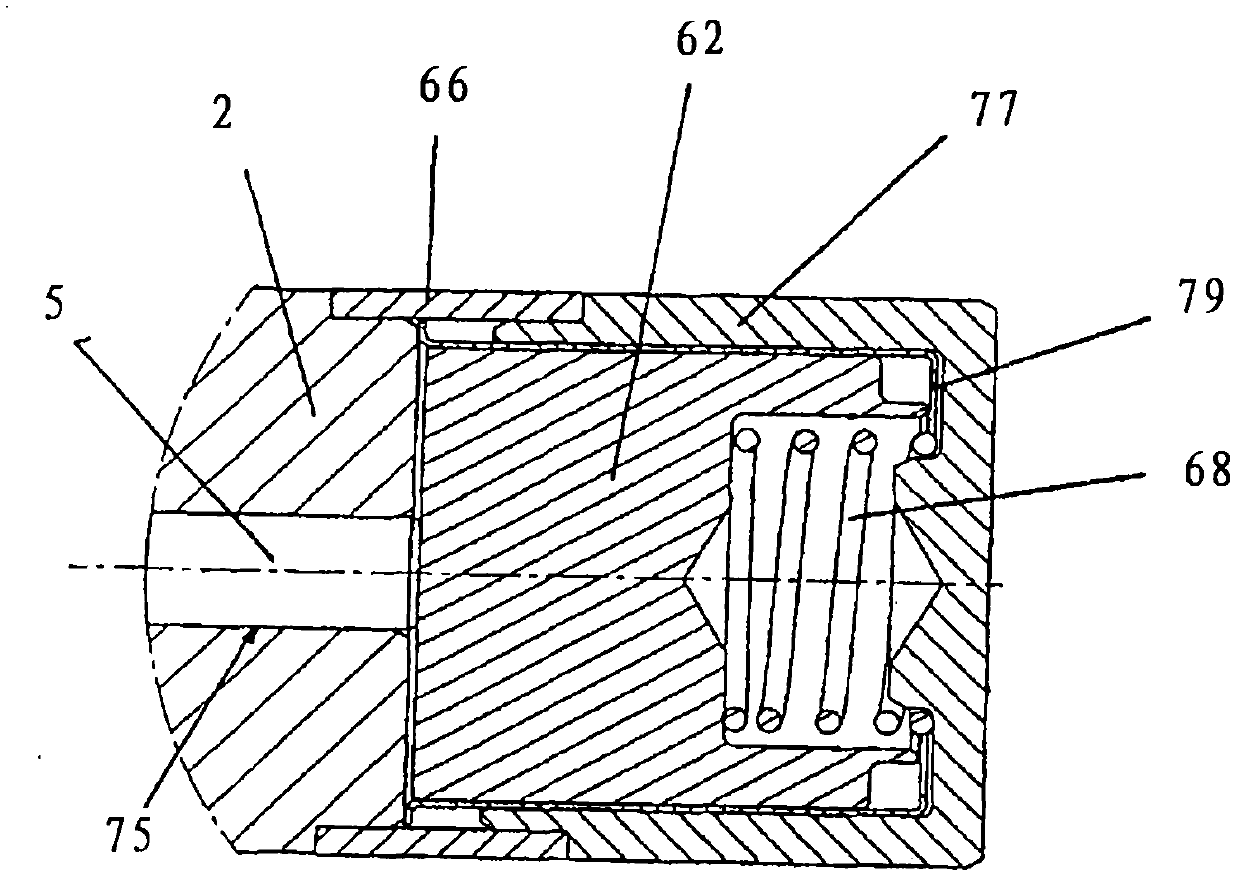

[0023] figure 1 A cross section of the high-pressure regulating valve 1 of the present invention is shown. The high-pressure regulating valve 1 is substantially formed from a valve body 2 , which is rotationally symmetrical about a longitudinal axis, with an inlet 20 and an outlet 21 . Between the inlet 20 and the outlet 21 , a valve seat 3 made of hardened steel is pressed into the valve body 2 and has a valve opening 30 connecting the inlet 20 to the outlet 21 . In the exemplary embodiment, the outlet 21 is formed in the valve body 2 by a radially extending bore 23 .

[0024] The outlet-side end of the valve bore 30 can be closed by a sealing element 4 , which is designed as a sealing ball in the present exemplary embodiment. The closing force acting on the sealing ball 4 is transmitted from the rear via the operating element 5 configured as a valve pin in the present embodiment to the operating unit 6 arranged on the valve body 2, which is configured in the present embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com