Installation underpinning method for existing framed building reinforced by parallel seismic isolation supports

A seismic isolation bearing and frame building technology, which is applied in construction, building maintenance, building components, etc., can solve the problems of adding structural load conversion components in construction steps, construction complexity and unsafe factors, and save construction equipment and support. The effect of replacing components, reducing project cost and improving seismic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

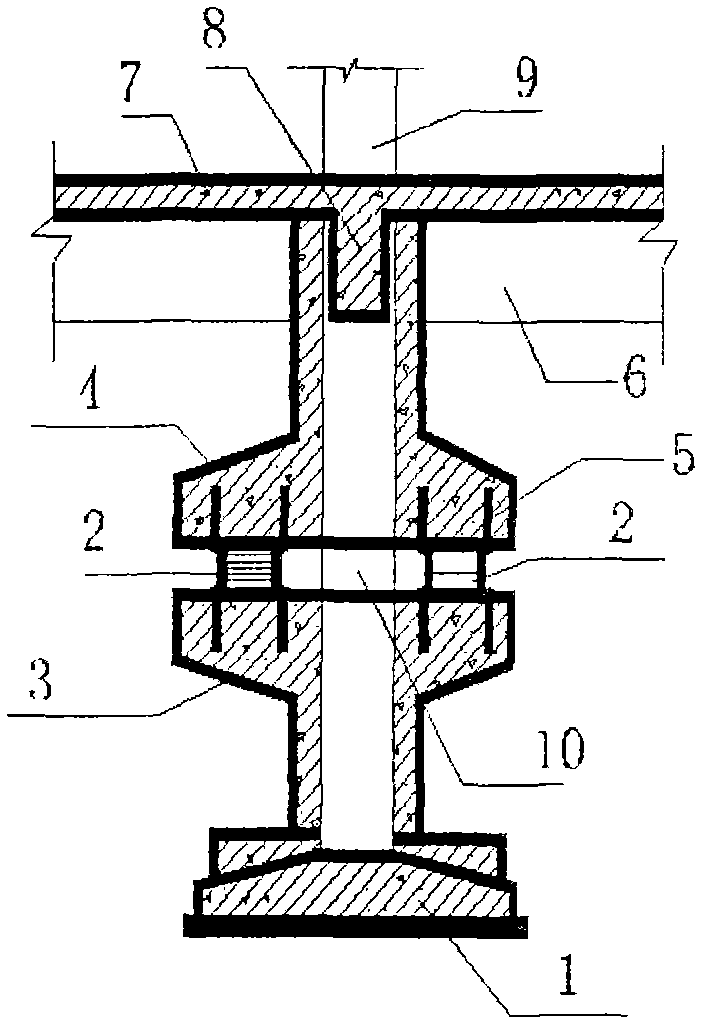

[0039] like Figure 1-3 As shown, a kind of existing frame building of the present invention adopts the installation underpinning method of parallel seismic isolation bearing reinforcement, comprises the following steps:

[0040] Step 1: Carry out base isolation and parallel isolation reinforcement design based on the existing frame building, and base on the plan layout of the isolation support, the combination form of the isolation support, the type of isolation support, and the isolation support design. Seat size and parameter combination verification seismic isolation support 2;

[0041] Step 2: Reinforce the foundation 1 of the existing frame building and the column 10 between the foundation 1 and the bottom beam 6 of the upper frame, and construct the upper and lower corbels 4, 3 of the shock-isolation support 2 around the column 10 according to the drawing design , wherein, two seismic isolation bearings 2 are set at the same horizontal position between the upper and lowe...

Embodiment 2

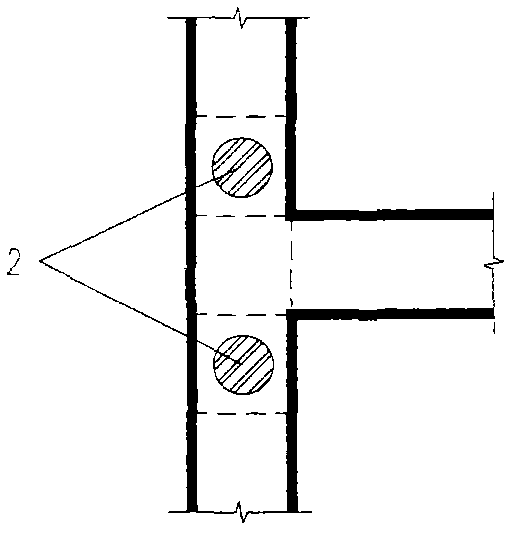

[0048] like Figure 4 As shown, an existing frame building of the present invention adopts an installation underpinning method reinforced by parallel seismic isolation bearings, wherein three seismic isolation bearings are arranged at the same horizontal position between the upper and lower corbels 4 and 3 of each column 10 2. It includes two rubber bearings and a frictional sliding bearing. These shock-isolation bearings 2 are connected in parallel and arranged in a "T" shape along the direction of the bottom beam 6 of the frame. Other steps are the same as in Example 1, and will not be described in detail here.

Embodiment 3

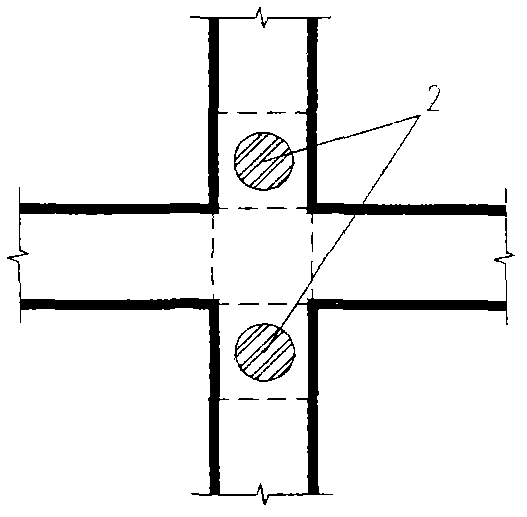

[0050] like Figure 5-6 As shown, an existing frame building of the present invention adopts an installation underpinning method reinforced by parallel seismic isolation bearings, in which 4 seismic isolation bearings are set at the same horizontal position between the upper and lower corbels 4 and 3 of each column 10 2. It includes two rubber bearings and two frictional sliding bearings. These seismic isolation bearings 2 are connected in parallel and arranged in a "+" shape along the direction of the bottom beam 6 of the frame. Other steps are the same as in Example 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com