Electric spinning machine

An electrospinning machine and electrospinning technology, applied in textiles and papermaking, fiber processing, filament/thread forming, etc., can solve problems such as volatile solutions and poor continuity of spun fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

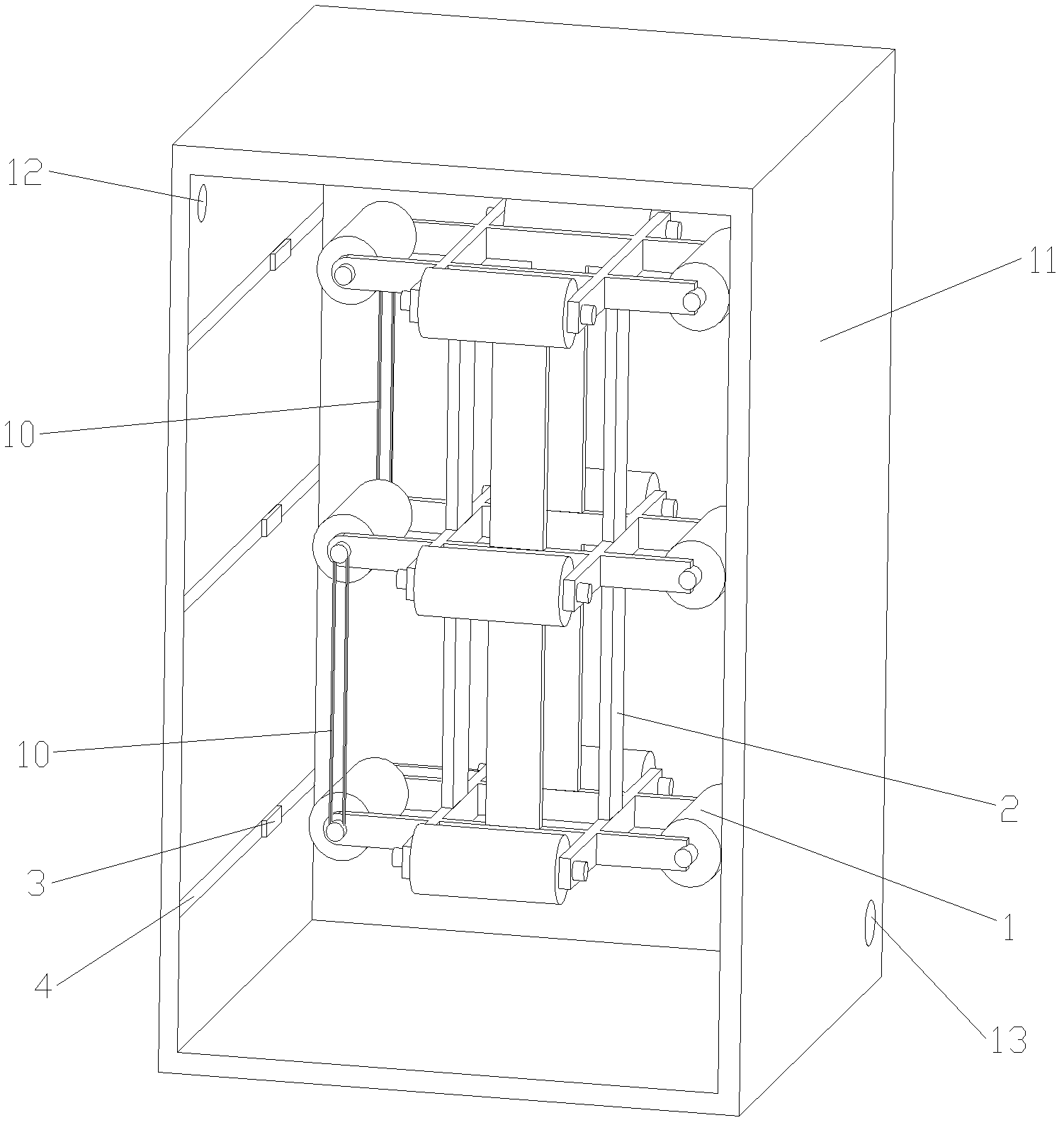

[0034] The electrospinning machine includes an electrospinning solution supply device, an electrospinning solution spinning device, a receiving device and a high-voltage electrostatic generator. Such as figure 1 As shown, the receiving device includes four receiving rollers 1 , and the receiving rollers 1 are all mounted on a support frame 2 . Along the axial direction of the receiving rollers 1, two receiving rollers 1 are arranged in a row; along the parallel direction of the receiving rollers 1, the receiving rollers 1 are arranged in two rows. A row of receiving rollers 1 is a group, and the receiving rollers 1 of the same group are driven by gears and rotated by motors; the two receiving rollers 1 of the same group rotate at the same speed, and the speed can be adjusted at the same time. The spray head 3 is arranged directly above the receiving roller 1 , and the four receiving rollers 1 correspond to the four spray heads 3 , and the spray head 3 is installed on the brac...

Embodiment 2

[0039] The electrospinning machine includes an electrospinning solution supply device, an electrospinning solution spinning device, a receiving device, a vacuum box 11 and a high-voltage electrostatic generator. image 3 As shown, the receiving roller 1 of the receiving device has a multi-layer ring structure. Twelve receiving rollers 1 are arranged in three layers, four in each layer form a circle, and corresponding vertical receiving rollers 1 between different horizontal planes are parallel to each other. Three parallel receiving rollers 1 in a vertical row form a group, driven by a motor, and the adjacent receiving rollers 1 are driven by a belt 10, so that the same group of receiving rollers 1 rotate and receive at the same speed, and the speed can be adjusted at the same time.

[0040] The outside of each receiving roller 1 is provided with a spray nozzle 3 ( image 3 Not all twelve nozzles are shown). The spray head 3 reciprocates along the axial direction of the rece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com