Overall assembly device for valve 120 module

A technology for assembling devices and valve modules, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the assembly quality of the braking system, the alignment of the installation holes, and the strong assembly, so as to save the assembly site space and assemble High precision and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is further described.

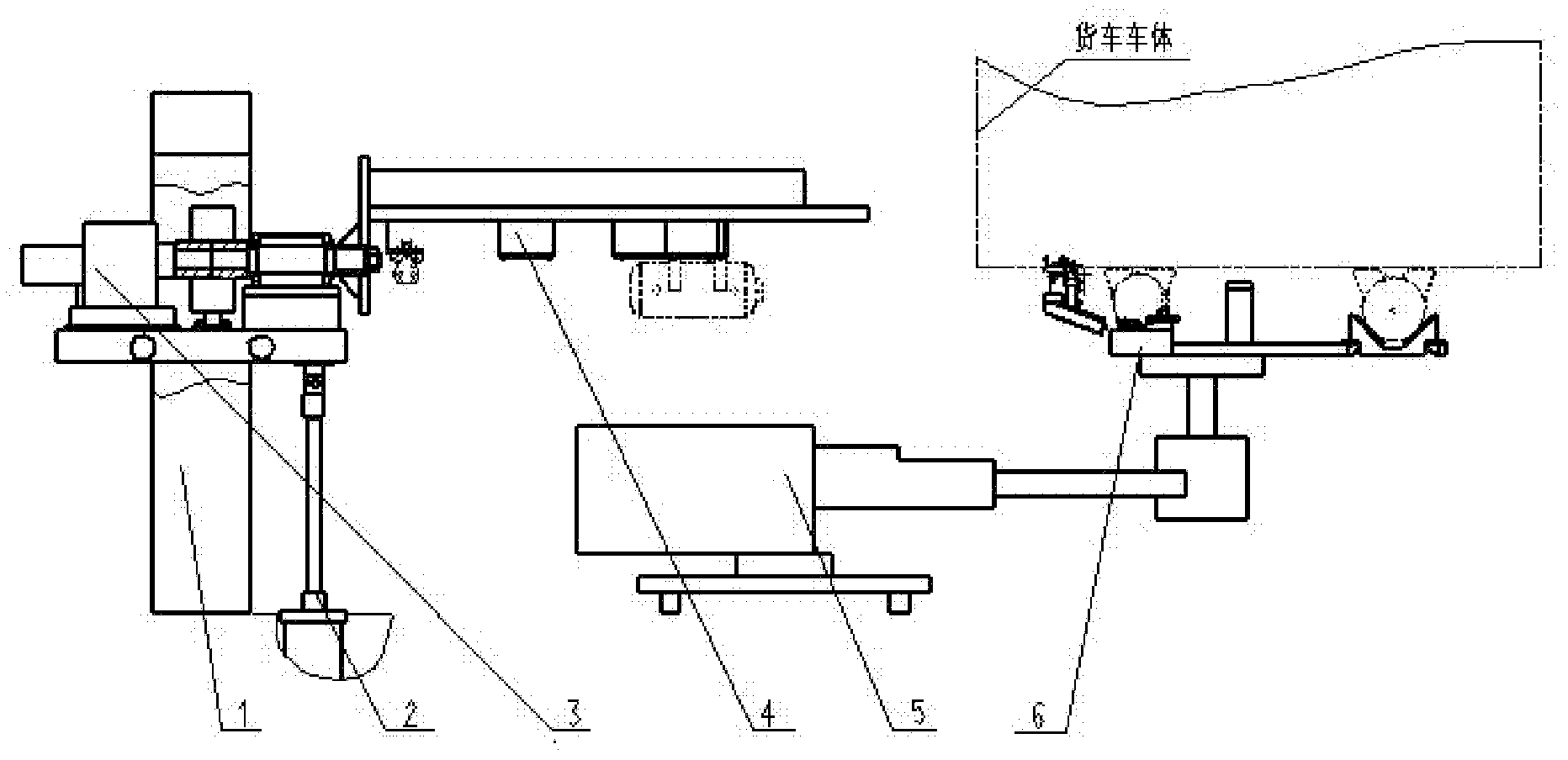

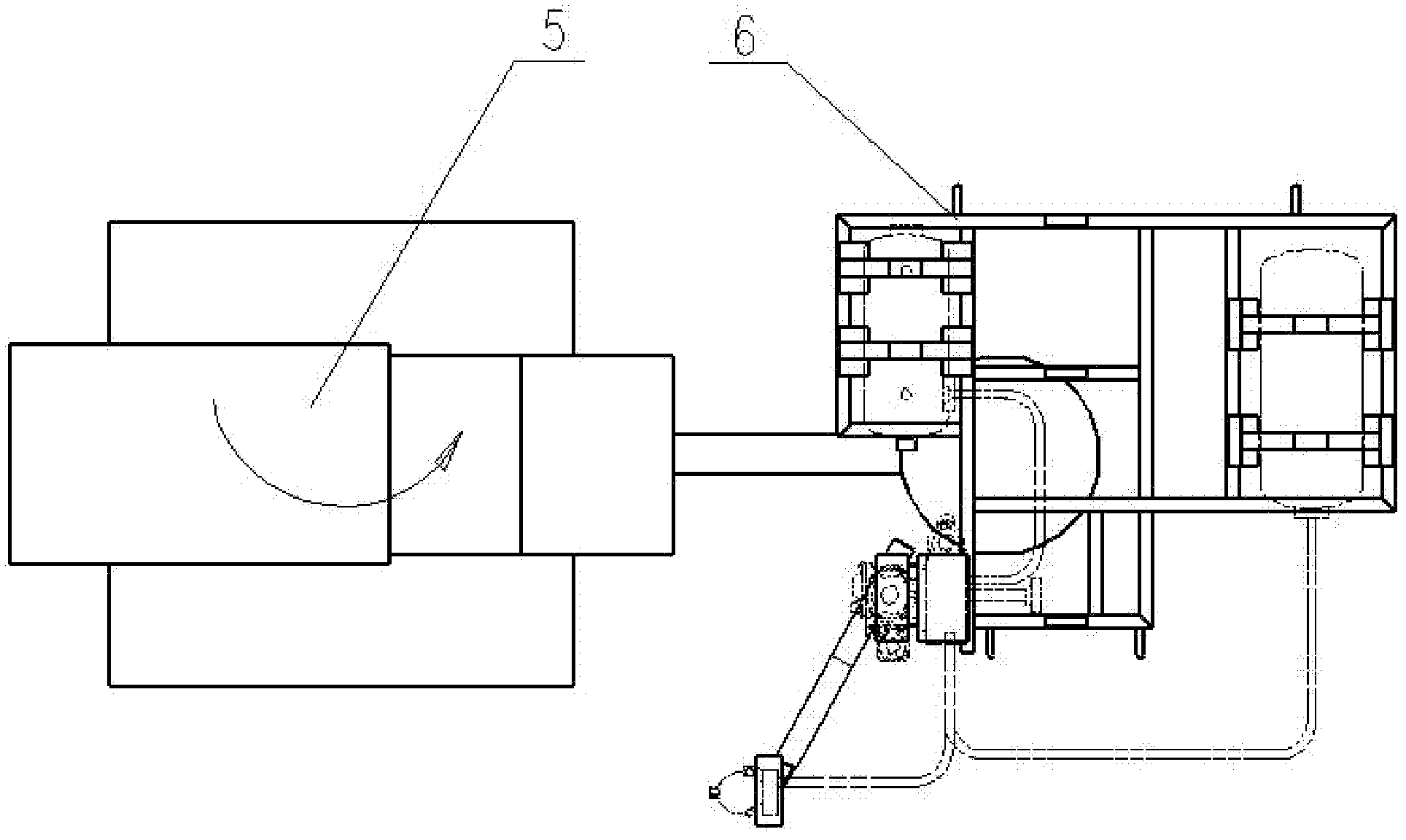

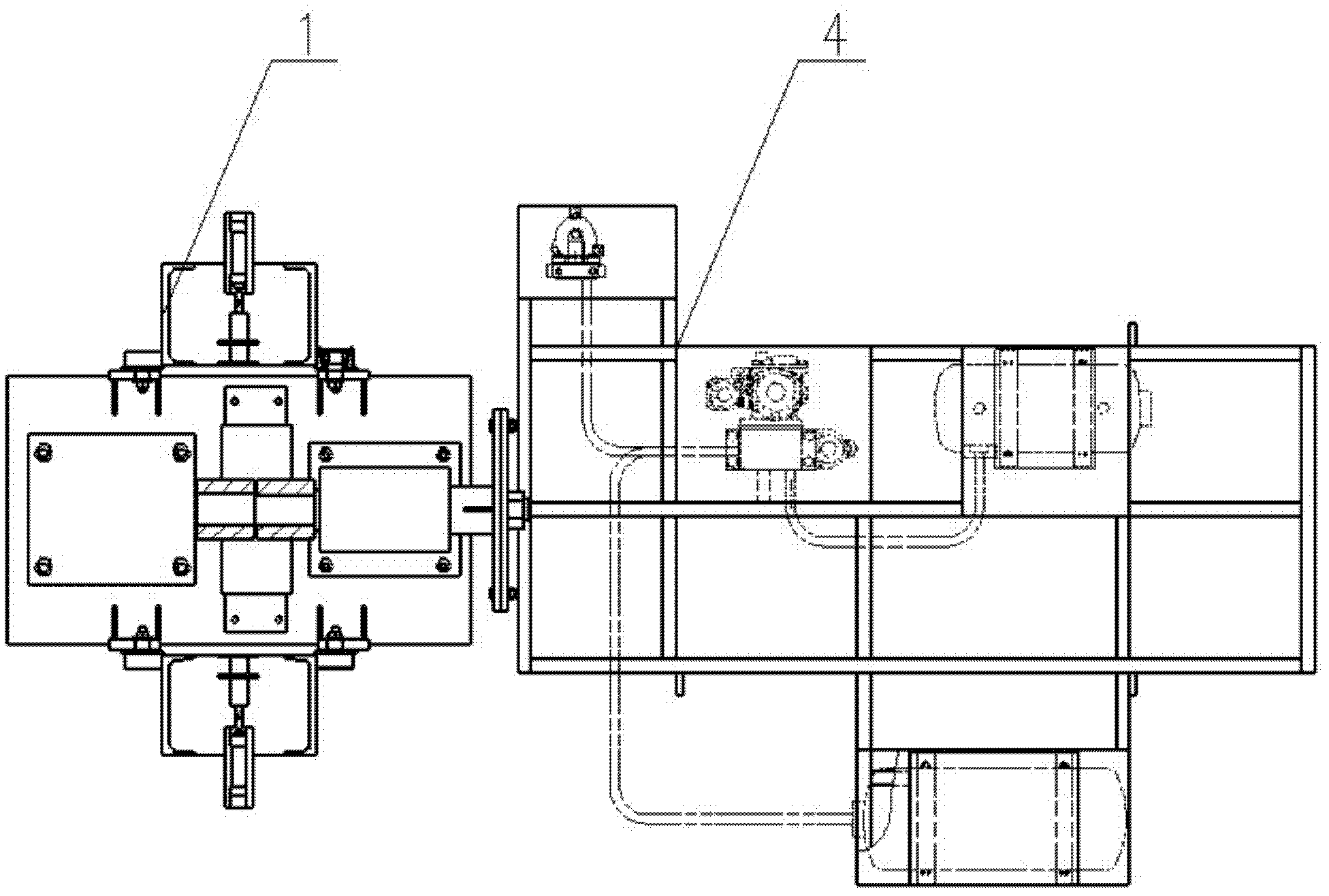

[0032] see figure 1 —15,120 The overall assembly device of the valve module includes a column 1, and also includes a lifting mechanism 2, an overturning mechanism 3, an anti-assembly platform 4, a manipulator 5, and a positive assembly platform 6; The platform 2-1, the lifting cylinder 2-2, the guide part 2-3, and the locking part 2-4 are composed; the turning mechanism 3 is installed on the lifting platform 2-1, and the turning mechanism 3 is composed of a motor 3-1, a reducer 3-2, brake 3-3, coupling 3-4, module mounting seat 3-5; the module mounting seat 3-5 is connected with the anti-assembly platform 4; the anti-assembly platform 4 is composed of tire frame 4-1, pressure limiting Valve clamping device 4-2, 120 valve clamping device 4-3, 50 liter air cylinder clamping device 4-4, 11×17 liter air cylinder clamping device 4-5 are composed; manipulator 5 is composed of fixed seat 5-1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com