Combined two-roller continuous mill

A combined, continuous rolling mill technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of poor working environment, inconvenient maintenance, complex underground structure, etc., to reduce production costs and maintenance. Cost, reduction in length size, effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

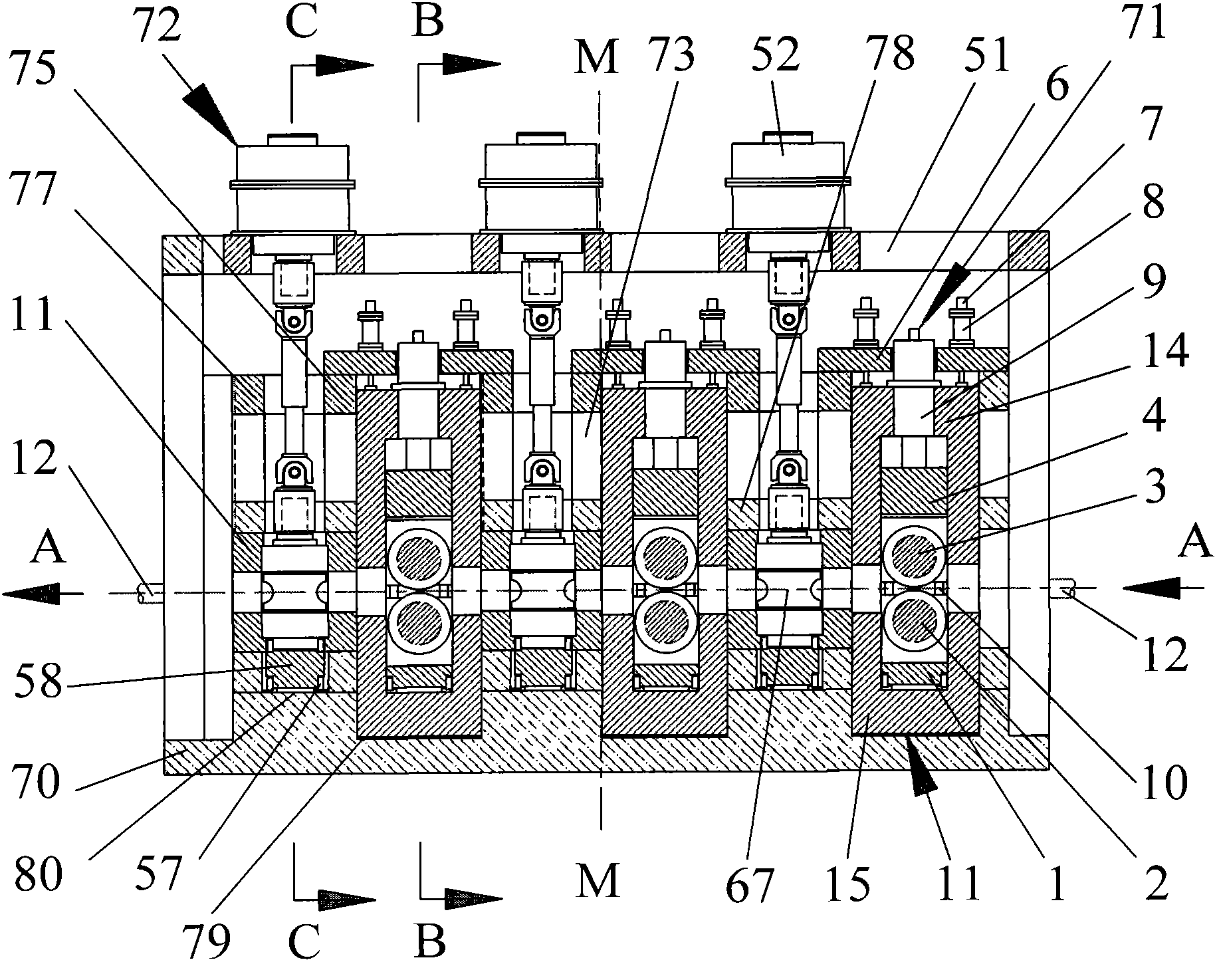

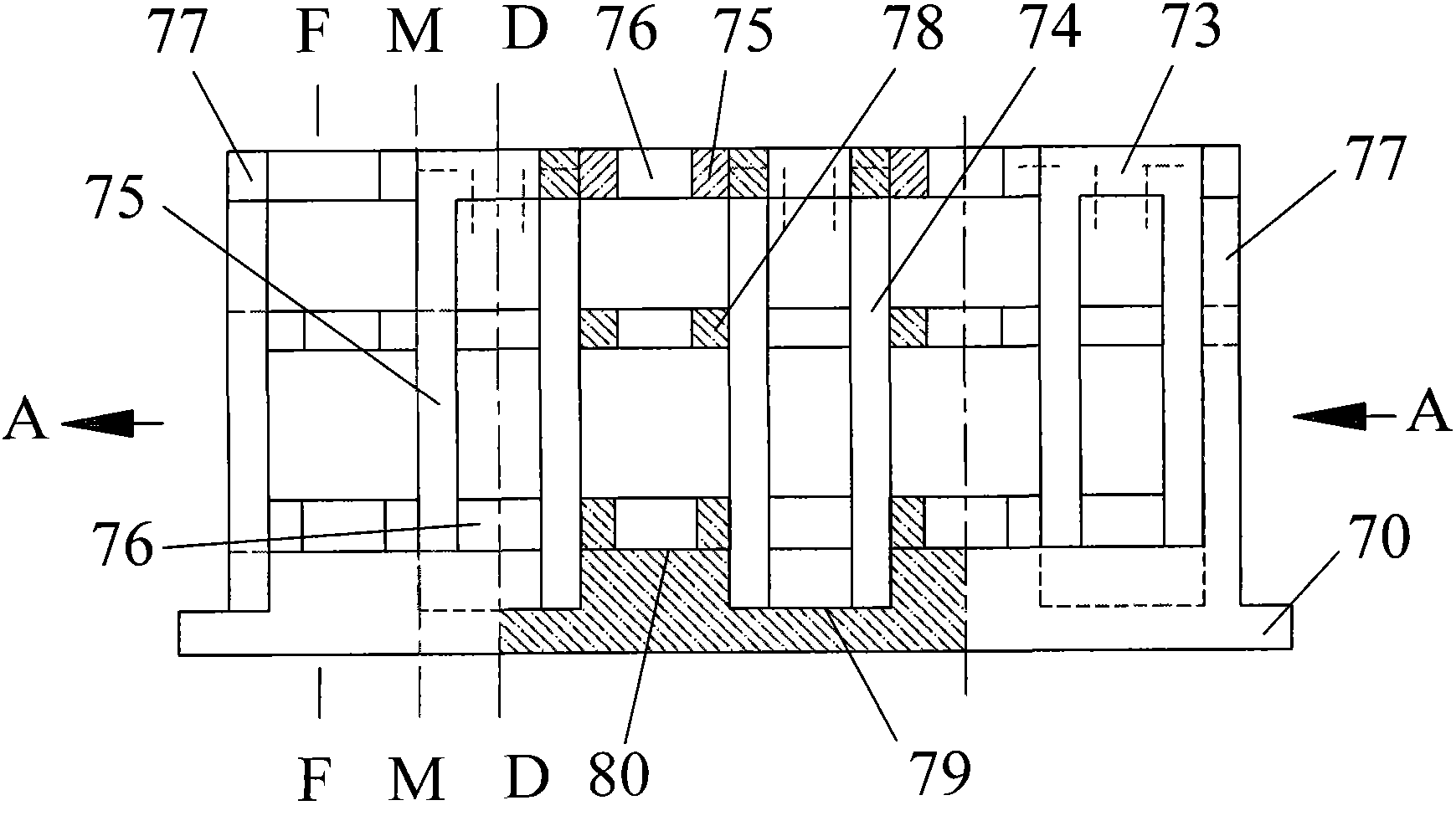

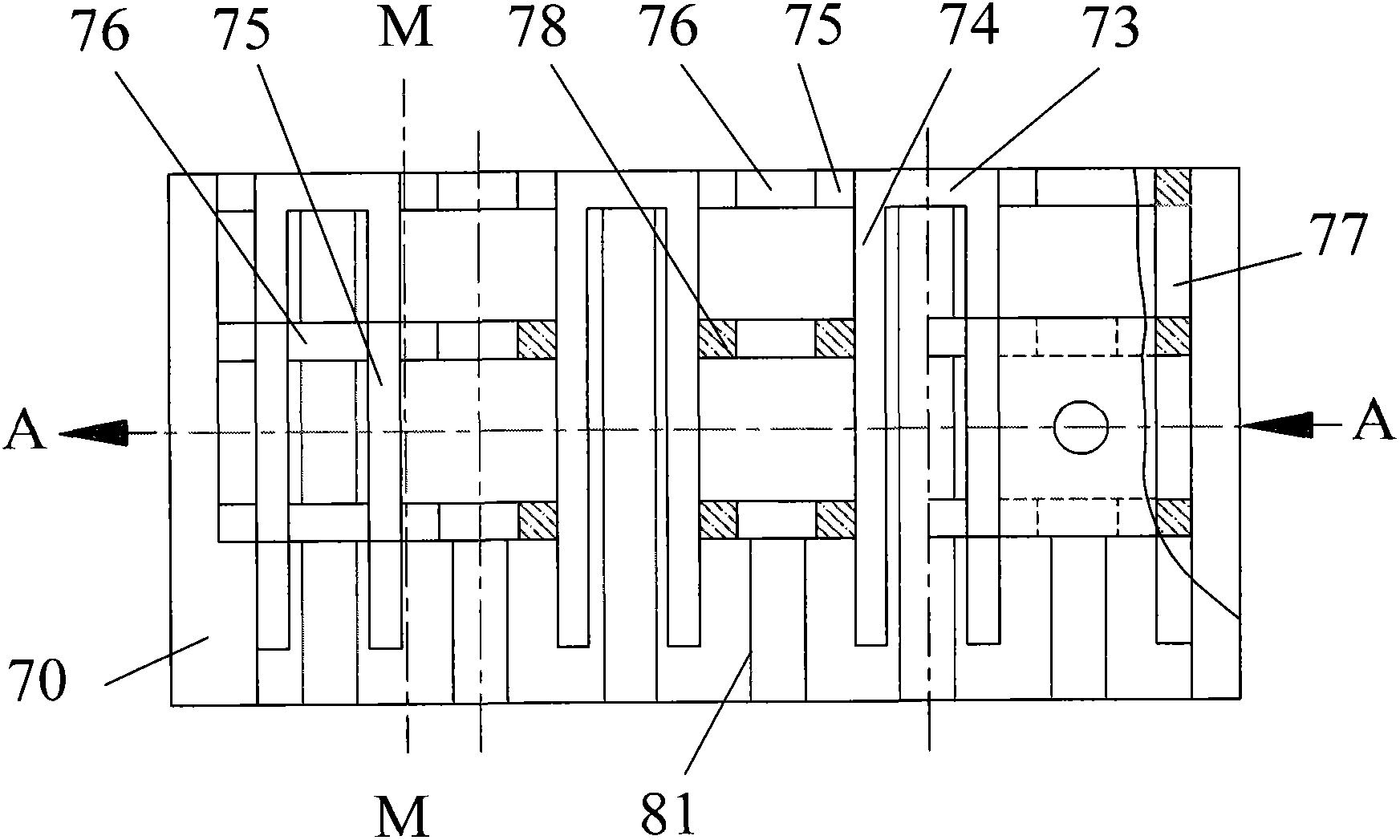

[0071] The specific implementation of the combined two-roll tandem rolling mill of the present invention will be further described below in conjunction with the accompanying drawings.

[0072] Existing horizontal rolling mill and vertical rolling mill respectively comprise: rolling stand, two rolls that are arranged in parallel with each other in the rolling stand, roll chock, roll balance mechanism 10, the roll gap adjusting mechanism that adjusts roll gap and roll changing mechanism. In order to minimize the overall length of the combined two-roll mill of the present invention along the rolling line A-A, the combined two-roll mill of the present invention is to alternate the horizontal rolling mill and the vertical rolling mill of the prior art. It is installed on the base of the same frame structure to form a combined continuous rolling mill.

[0073] see figure 1 , the combined two-roll tandem rolling mill of the present invention comprises a rolling mill base 5, on whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com