Filtration systems for chemical fluids

A filtration system and fluid technology, applied in the direction of filtration and separation, mining fluid, chemical instruments and methods, etc., can solve the problems of restricting ROV access, cost, time-consuming, etc., and achieve the effect of rapid connection/disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

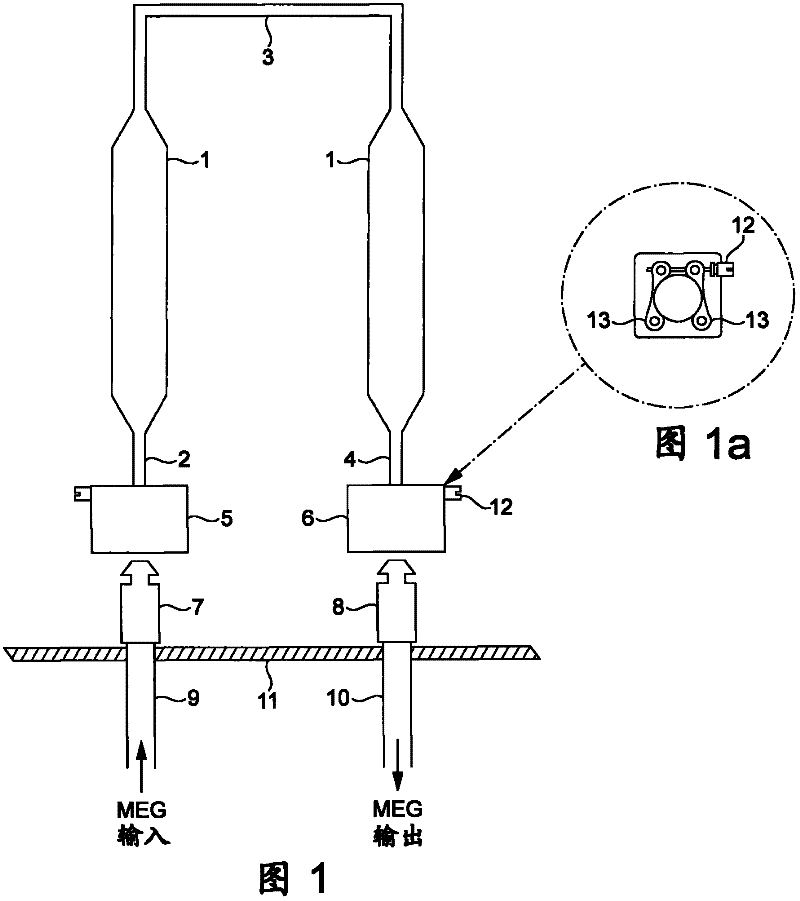

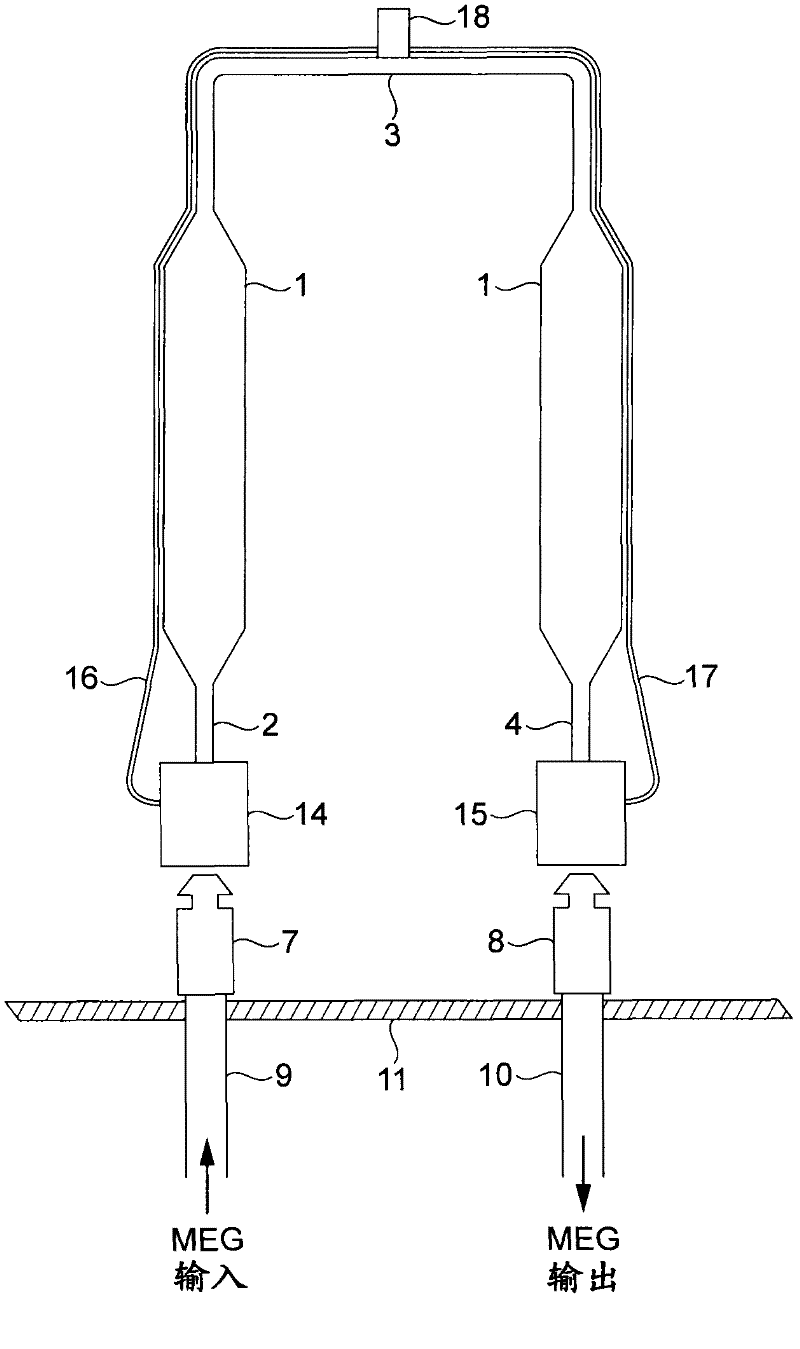

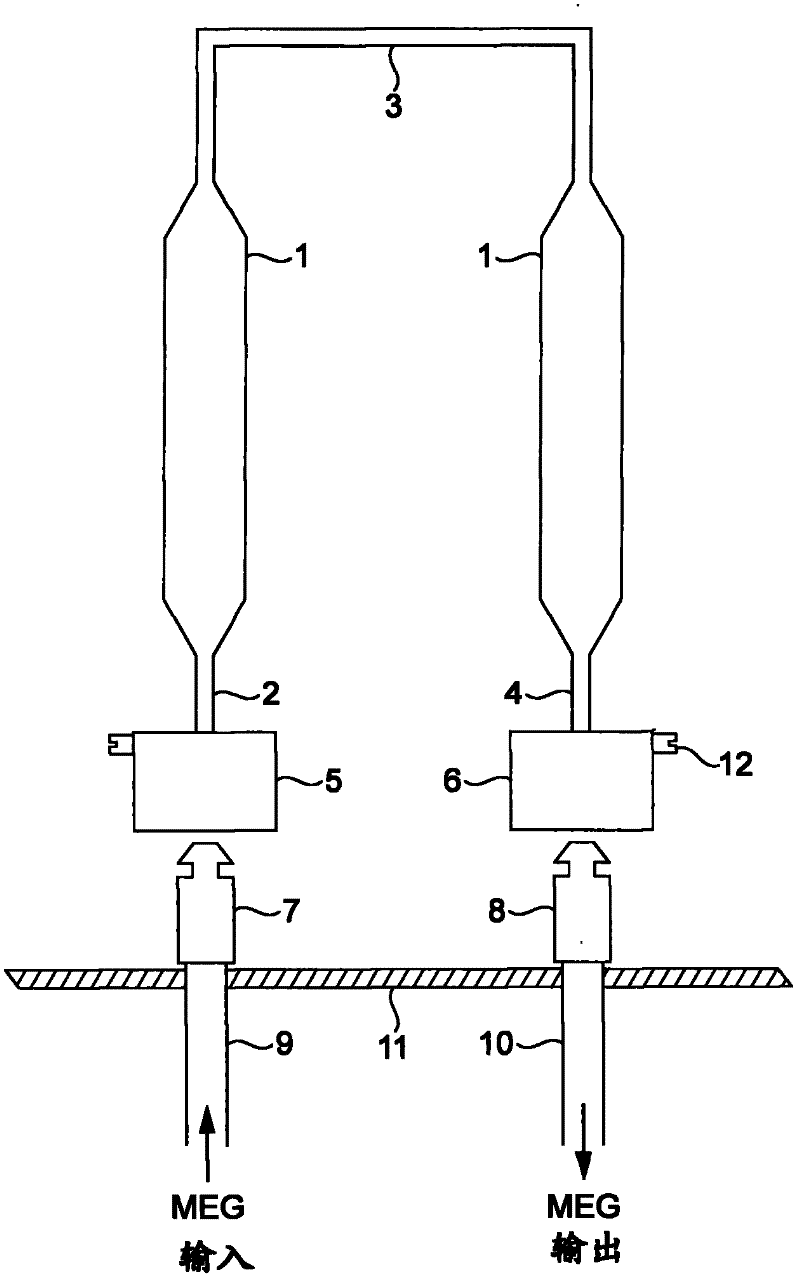

[0015] figure 2 (where, with figure 1 Items in the corresponding items in figure 1 with the same reference numerals in ) shows an application of the invention comprising the introduction of hydraulically operated connectors 14 and 15 in an annular flow line instead of connectors 5 and 6 . As an example, each connector 14 and 15 is a Vetco Gray 21 / 16" flow line hydraulic connector part number A110312-9 used to connect the MEG filter assembly to a semi-permanent base. These connectors require hydraulic actuation hydraulic actuation through hydraulic lines 16 and 17, respectively, at the top of a 180-degree loop to a vertically mounted ROV hot stab connector section 18, which is in the filter on the apex area 3 of the filter assembly. The hydraulic connectors 14 and 15 are self-sealing, preventing seawater ingress and MEG exhaust during filter assembly changes. Each connector has heat from the ROV on two separate circuits. The supply of the entry button hydraulically drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com