Food processor with piston type sealing device

A technology for food processors and sealing devices, which can be applied to utensils with integral electric heating devices, household utensils, applications, etc., and can solve the problem that the lid is not sealed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

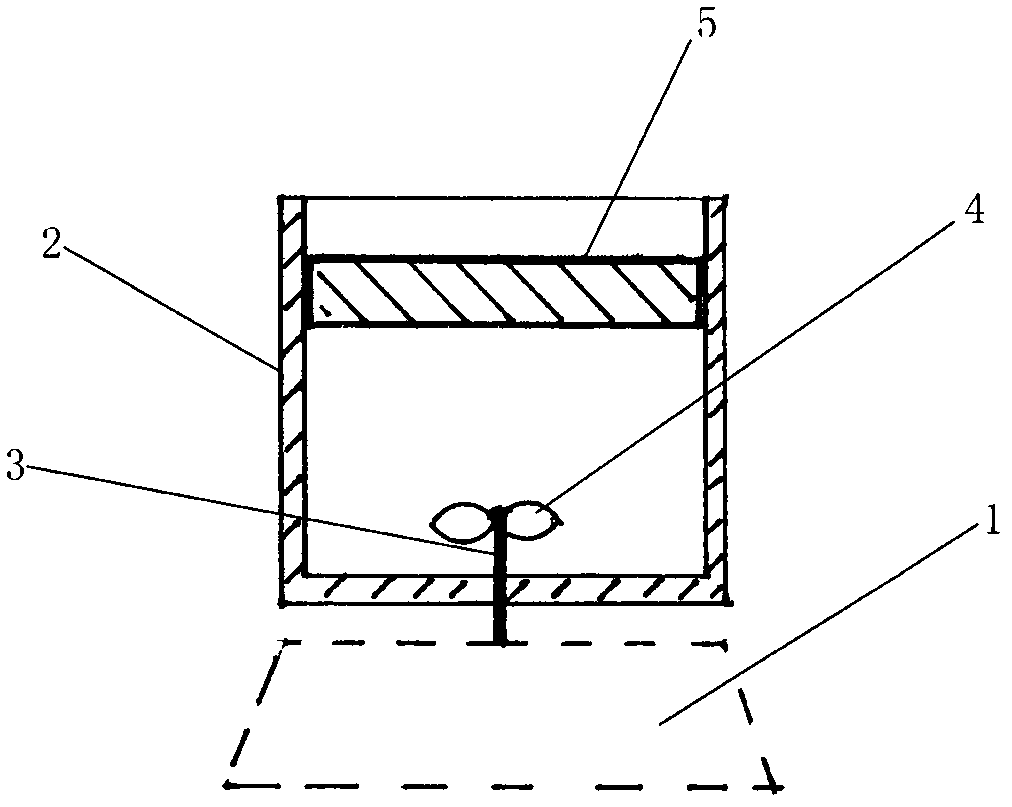

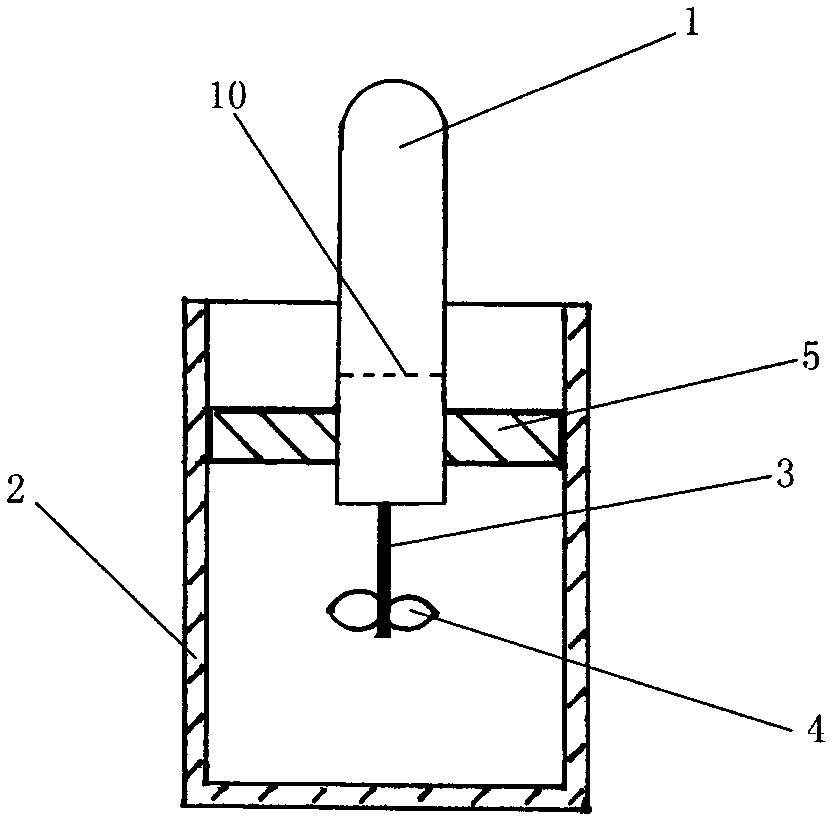

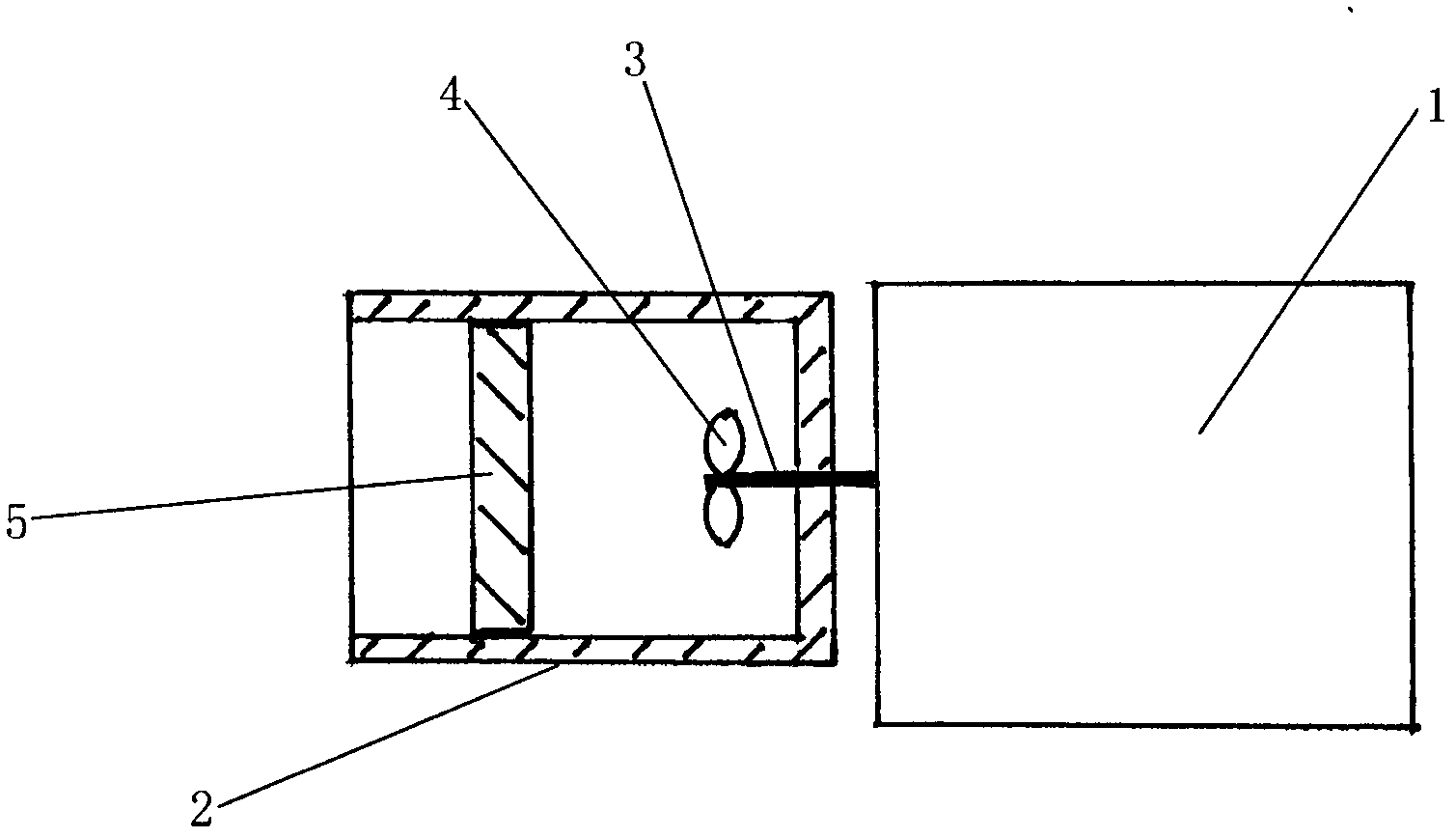

[0087] The present invention is further described below in conjunction with the examples.

[0088] As shown in the figure, machine base (head) 1; bucket body 2; cutter shaft 3; cutter 4; piston type sealing device 5; pressure spring 6; tightening knob 7;

[0089] (of barrel 2) longitudinal axis Z;

[0090] (on the machine head 1) upper cover 11; (on the machine head 1) lower cover 12;

[0091] Piston main body 51; central shaft 511; central shaft pin 511'; fixed pile 512; pressing plate 513; pressing plate hole 5130; annular groove 514; barrel cover 515; barrel cover hole 5150;

[0092] (Piston) seal ring groove 52; seal ring 522; seal ring thickening part 522';

[0093] Air vent 53; Movable plug 533; Lock pin 533'; One-way valve 531;

[0094] Handle 54; handle hole 540; handle center hole 541; handle shaft hole 542; handle chuck 543; handle shaft 544;

[0095] Feeding hole 55; Feeding hole cover 555;

[0096] Suction cylinder 8; Suction piston 81; Suction rod 82; Suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com