On-line monitoring device and method for preparing tobacco essence perfume

A technology of essence and fragrance for tobacco, which is applied in the direction of total factory control, total factory control, electrical program control, etc., and can solve problems such as long analysis time, complicated chromatographic analysis and processing, and insufficient sensitivity of the blending process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

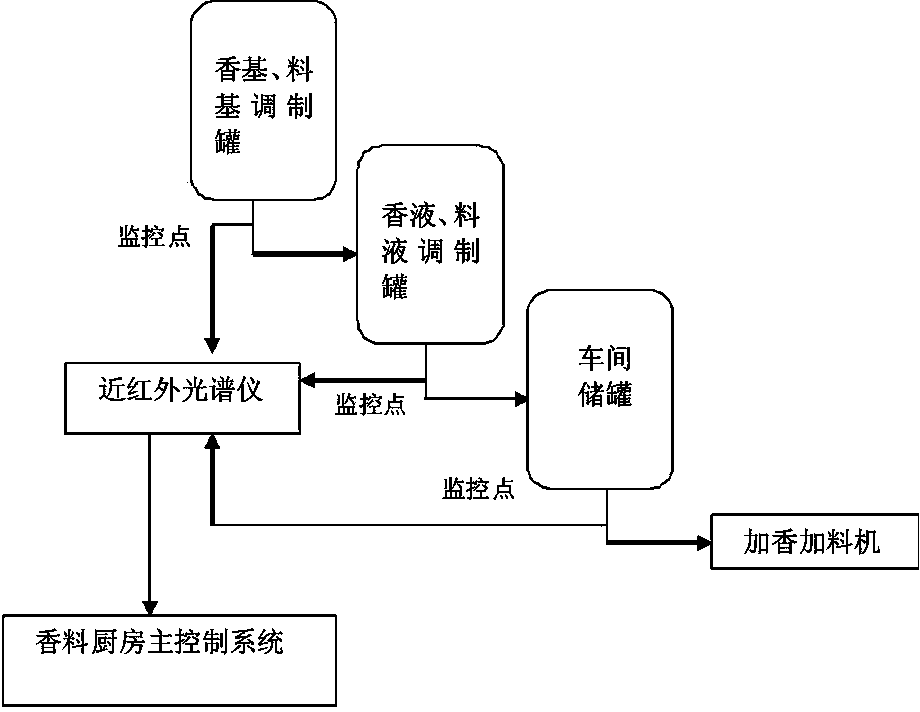

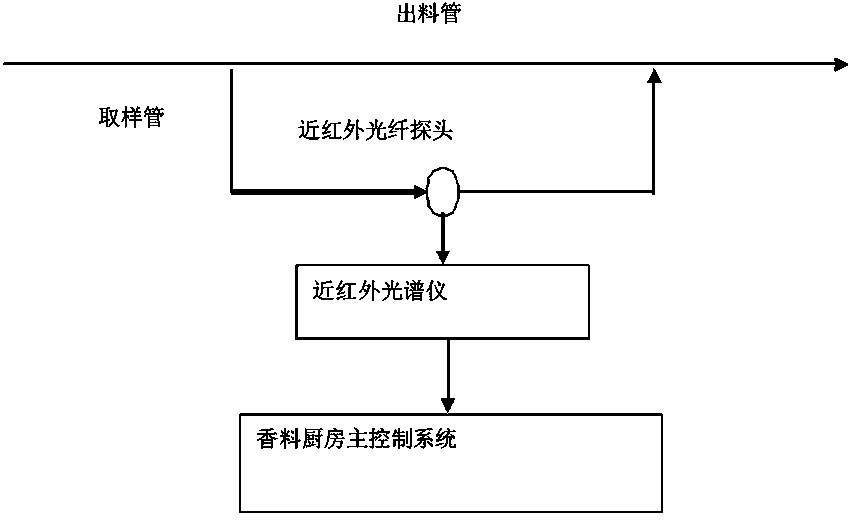

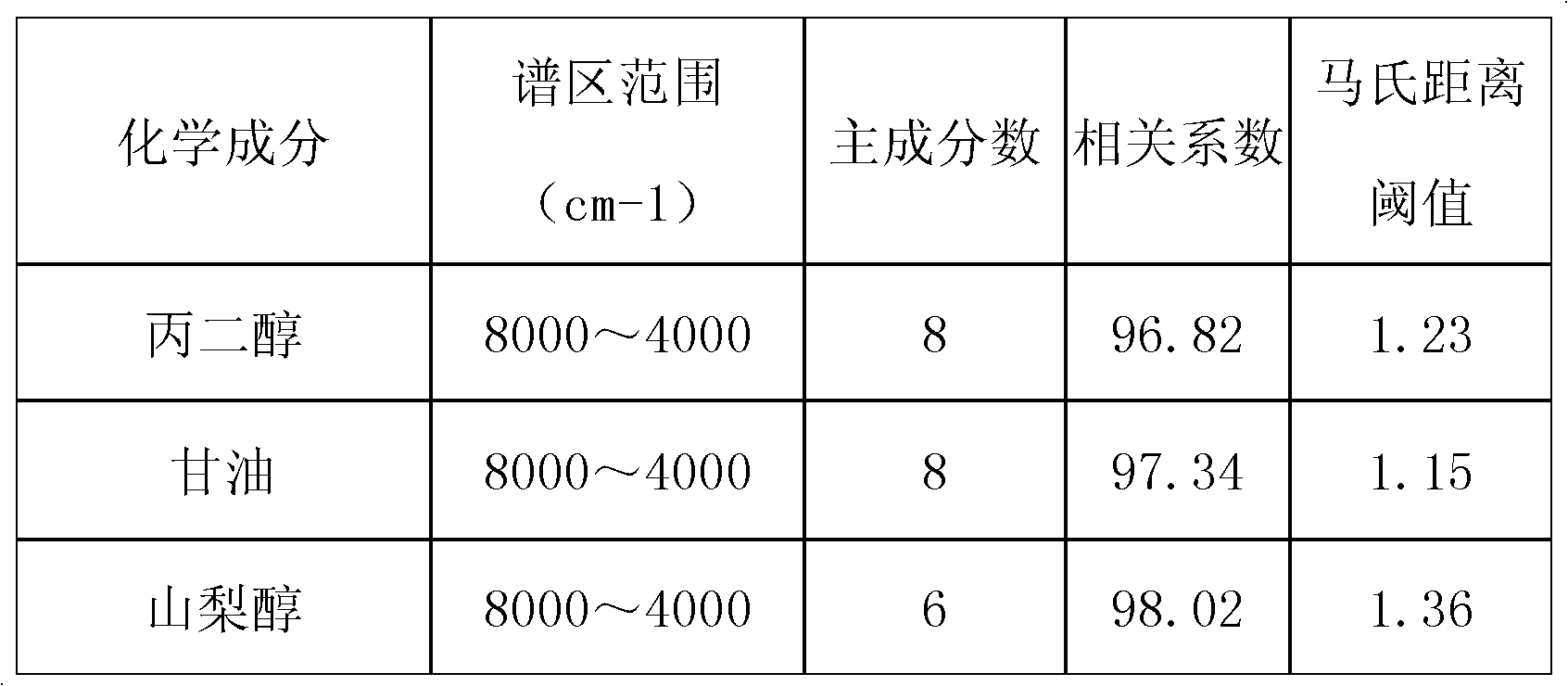

[0021] Such as figure 1 As shown, there are mainly the following process monitoring points in the blending process of flavors and fragrances for tobacco: fragrance base, material base preparation tank discharge, fragrance liquid, feed liquid preparation tank discharge and workshop storage tank discharge. Such as figure 2 As shown, sampling pipes are installed on the discharge pipes of the above-mentioned process monitoring points, and near-infrared optical fiber probes are installed behind the sampling pipes, and the probes are connected to near-infrared spectrometers through optical fibers. Such as figure 1 As shown, multiple near-infrared optical fiber probes at different monitoring points share a near-infrared spectrometer, and the near-infrared spectrometer is incorporated into the main control system of the spice kitchen through the data line. The near-infrared spectrometer control system is embedded in the main control system of the spice kitchen, and the near-infrare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com