Build-up force standard machine with wide range,

A large-scale, superimposed technology, applied in the direction of calibration/testing of force/torque/power measuring instruments, measuring devices, weighing equipment testing/calibration, etc., can solve the problem of increasing labor intensity, increasing costs, affecting the accuracy of standard sensors, etc. Problems, to achieve the effect of wide application range, low production cost, and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

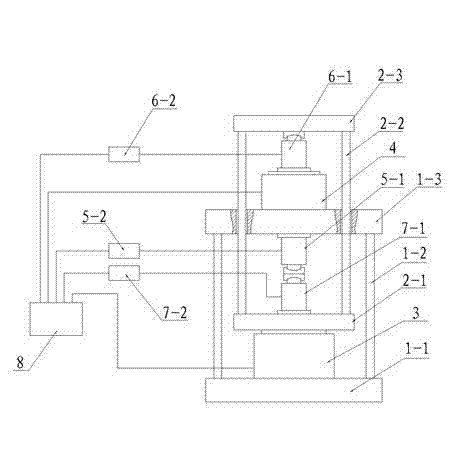

[0033] Such as figure 1 As shown, a superimposed force standard machine with a large range of the present invention includes: a main frame 1, a reverser 2, a large-range force-measuring cylinder 3, a small-range force-measuring cylinder 4, and a large-range standard sensor 5-1 , large-range standard sensor meter 5-2, small-range standard sensor 6-1, small-range standard sensor meter 6-2, tested sensor 7-1, tested sensor meter 7-2, servo control system 8, etc. Among them: the main frame 1 is composed of the main frame bottom plate 1-1, the main frame column 1-2, the main frame upper beam 1-3, the reverser 2 is composed of the reverser lower pressure plate 2-1, and the reverser pull rod 2-2 , and the upper platen 2-3 of the reverser is composed.

[0034]The large-range force-measuring cylinder 3 is installed on the main frame bottom plate 1-1, and the measured sensor 7-1 is installed on the lower pressure plate 2-1 of the reverser. -1 is separated, and the large-range force me...

Embodiment 2

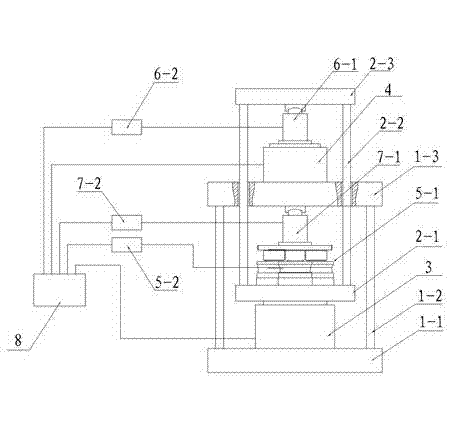

[0042] figure 2 Another embodiment of the present invention is shown. In this embodiment, the large-range standard sensor 5-1 is composed of three sensors connected in parallel, and is installed on the lower platen 2-1 of the reverser 2. Its working mode Same as Example 1.

[0043]

Embodiment 3

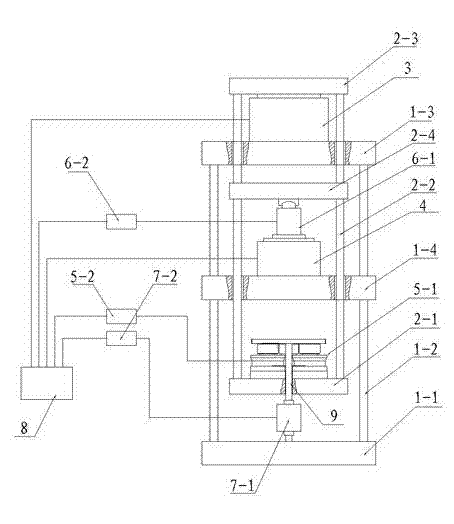

[0045] image 3 It is an embodiment of the present invention that adopts a dual-purpose structure of tension and compression. The difference between it and Embodiment 1 is that: the main frame 1 has a main frame middle beam 1-4, and the reverser 2 has a reverser middle pressure plate 2- 4. A large-range standard sensor reverse pull rod 9 is set on the large-range standard sensor 5-1, and the small-range force-measuring cylinder 4 and the large-range force-measuring cylinder 3 respectively pass through the middle pressure plate 2-4 of the reverser and the reverser The upper platen 2-3 exerts force, but its force measurement principle is the same as figure 1 The structures shown are exactly the same, and the detection of the pulling force of the measured sensor 7-1 is realized by a large-range standard sensor reverse pull rod 9 arranged on the large-range sensor 5-1, and the large-range force sensor 5-1 Between the base plate 1-1 of the mainframe frame is a tension test space, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com