Joint bearing device for vacuum vessel

A technology of vacuum containers and carrying devices, which is applied in the direction of measuring devices, instruments, measuring instrument components, etc., and can solve the problem that the load-bearing capacity of the vacuum container platform cannot meet the test products and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further elaborated in conjunction with specific implementation:

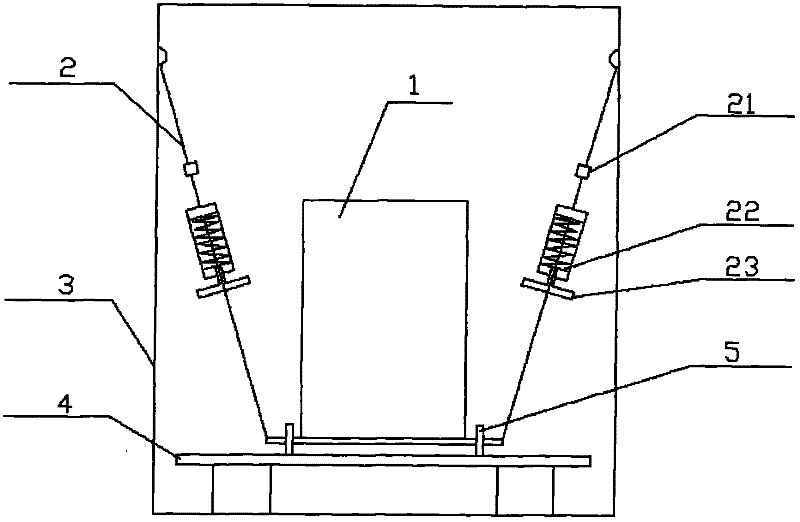

[0016] see figure 1 , a combined bearing device used in a vacuum container, comprising a boom 2, a vacuum container 3, a bottom operating platform 4, a guide pin 5 and a mounting base, wherein the bottom operating platform 4 is installed on the vacuum container 3 The bottom of the vacuum container, the installation base is fixed on the bottom operating platform through guide pins, the outer edge of the installation base is evenly distributed with a plurality of connecting parts in the circumferential direction, the upper part of the inner wall of the vacuum container is provided with the same number of lifting points as the connecting parts One end of the rod 2 is connected to a plurality of connecting pieces, and the other end is connected to a plurality of hanging points.

[0017] Wherein the boom includes a force sensor 21, a compression spring 22 and an adjustment nut 23, the force s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com