Lifting pressurized well-repairing technology in closed oil pipe

A kind of oil pipe and workover technology, which is applied in the direction of drilling pipe, casing, drilling equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

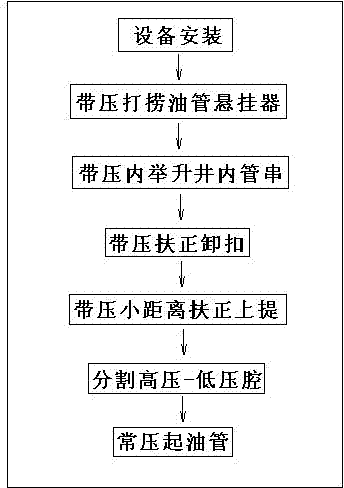

[0024] The lifting and pressure workover process in the closed tubing is characterized in that it at least includes the following steps:

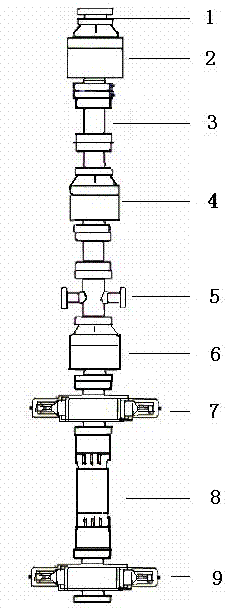

[0025] Step 1. Equipment installation, namely: the installation of the lifting and pressure workover device in the sealed tubing;

[0026] Step 2. Under pressure salvage tubing hanger;

[0027] Step 3, lifting the pipe string in the well under pressure;

[0028] Step 4. Righting the shackle with pressure;

[0029] Step 5. Lifting upright with small distance under pressure;

[0030] Step 6. Divide the high-pressure and low-pressure chambers;

[0031] Step 7. Lift the tubing under normal pressure.

Embodiment 2

[0033] as attached figure 1 As shown, when carrying out oil and gas well pressure operation, by adopting this process, the unblocked oil pipe under pressure in the oil and gas well can be actively lifted and pressed down in the high-pressure chamber of the device, and the oil pipe can be adjusted in the high-pressure chamber according to the operation needs. And the tools in the well are straightened and the operation is to make up and break out, realize the separation of high and low pressure in the device cavity, and enable the wellhead operators to realize normal pressure tripping operations.

[0034] The steps are explained in detail as follows:

[0035] Step 1. Equipment installation, namely: the installation of the lifting and pressure workover device in the sealed tubing;

[0036] 1) Check and pressure test the installed lifting and workover device in the sealed tubing;

[0037] 2) Use the temporary plugging tool in the wellhead oil pipe to temporarily block the oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com