Zinc-aluminum alloy material with high vibration absorbance and high tensile strength

A zinc-aluminum alloy and shock-absorbing technology, which is applied in the field of zinc-aluminum alloy materials with high shock absorption and high tensile strength, can solve the problems of easy vibration, high manufacturing cost, and increased vehicle noise, and achieves increased Weight, Satisfying Castability, Reduced Amplitude Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

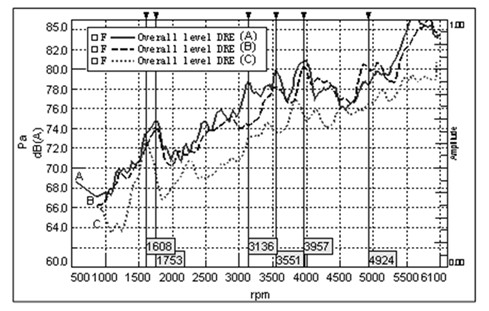

Image

Examples

Embodiment 1

[0017] Example 1: Take 30kg of pure aluminum, 45kg of zinc alloy whose gold plate is ZZnAI4Cu1Y, and 3kg of silicon, and prepare it by using a conventional aluminum alloy manufacturing process. The use method of the prepared zinc-aluminum alloy is the same as that of the existing aluminum alloy.

Embodiment 2

[0018] Example 2: Take 50 kg of pure aluminum, 65 kg of zinc alloy with the gold plate number ZZnAI4Cu1Y, and 8 kg of silicon, and use conventional aluminum alloy manufacturing techniques to produce it. The use method of the prepared zinc-aluminum alloy is the same as that of the existing aluminum alloy.

Embodiment 3

[0019] Example 3: Take 40kg of pure aluminum, 55kg of zinc alloy with the gold plate number ZZnAI4Cu1Y, and 5kg of silicon, and prepare it using a conventional aluminum alloy manufacturing process. The use method of the prepared zinc-aluminum alloy is the same as that of the existing aluminum alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com