Wire coil shelf

A wire reel and shelf technology, which is applied in the delivery of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of low warehouse utilization and overall degree, and incomplete goods, so as to improve space utilization and overall degree , reduce losses, improve the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

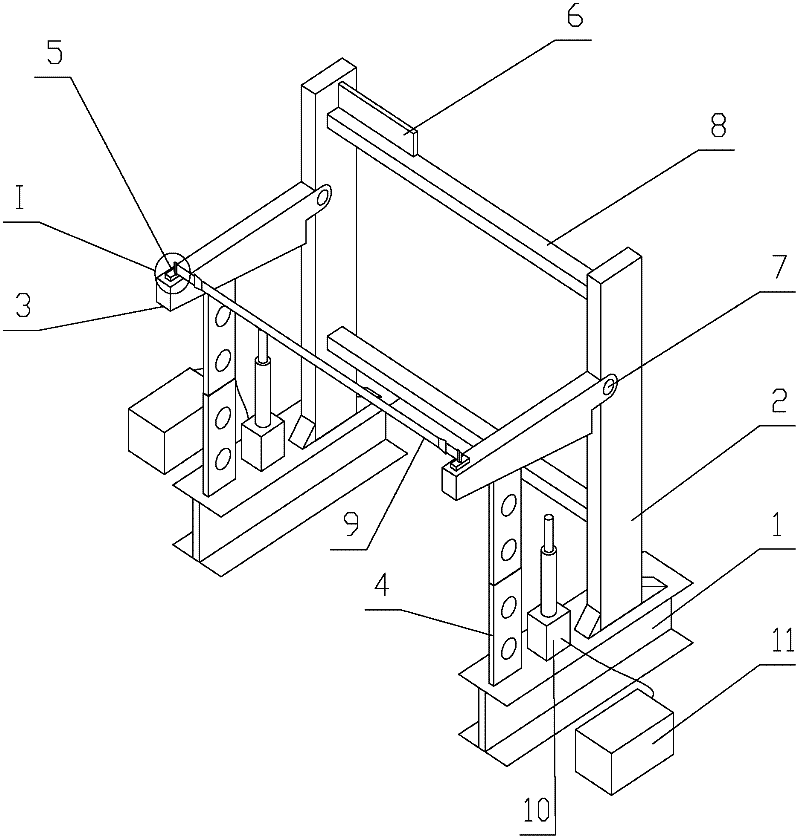

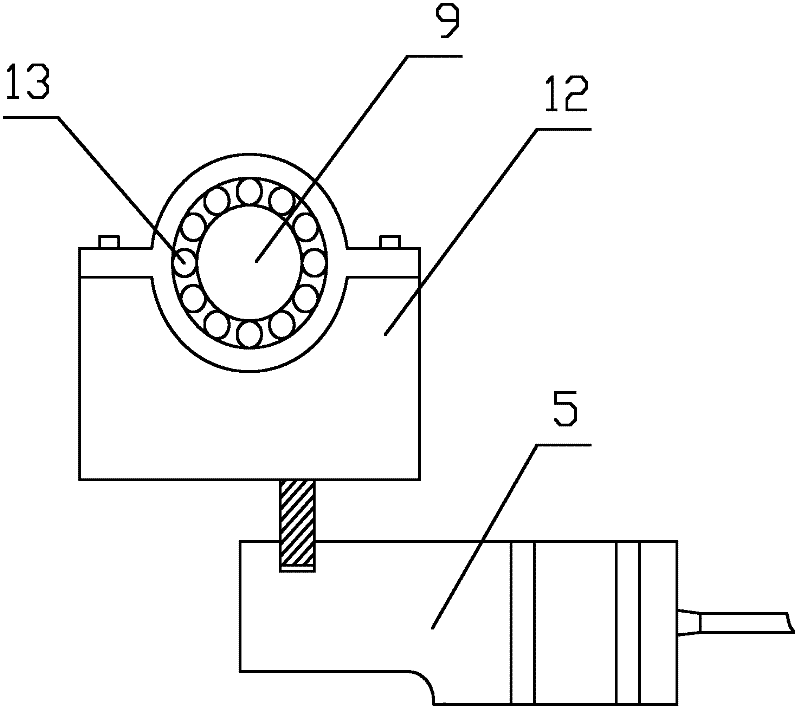

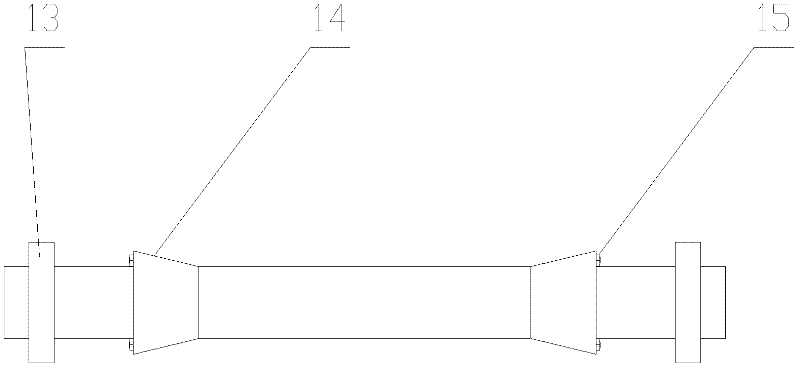

[0018] like figure 1 , figure 2 , image 3 As shown, the reel shelf includes a base 1, a column 2 arranged on both sides of the base 1, a cantilever 3 connected to the column 2 at one end, and an adjustable support 4 supporting the other end of the cantilever 3. The base 1 is provided with Lifting device, the cantilever 3 is provided with a weighing device, and the weighing device includes a load sensor 5 and an intelligent display controller 6 connected to the load sensor 5. The structure is simple and the connection is convenient. The load sensor 5 is provided with a bearing The base 12 is convenient for placing the wire reel, and the weight of the wire reel is converted into a number by the load sensor 5. Bearing 13, the bearing 13 cooperates with the bearing base 12. Through the setting of the bearing 13, friction and wear are reduced, the safety performance is good, and the service life of the support shaft 9 is improved. The gap between the support shaft 9 and the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com