Stacking system

A stacking system and rolling chain technology, which is applied to the stacking, transportation and packaging of objects, can solve the problems of high labor intensity, large space occupation, and low cost, and achieve wide application range, fast stacking speed, and low occupation cost. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

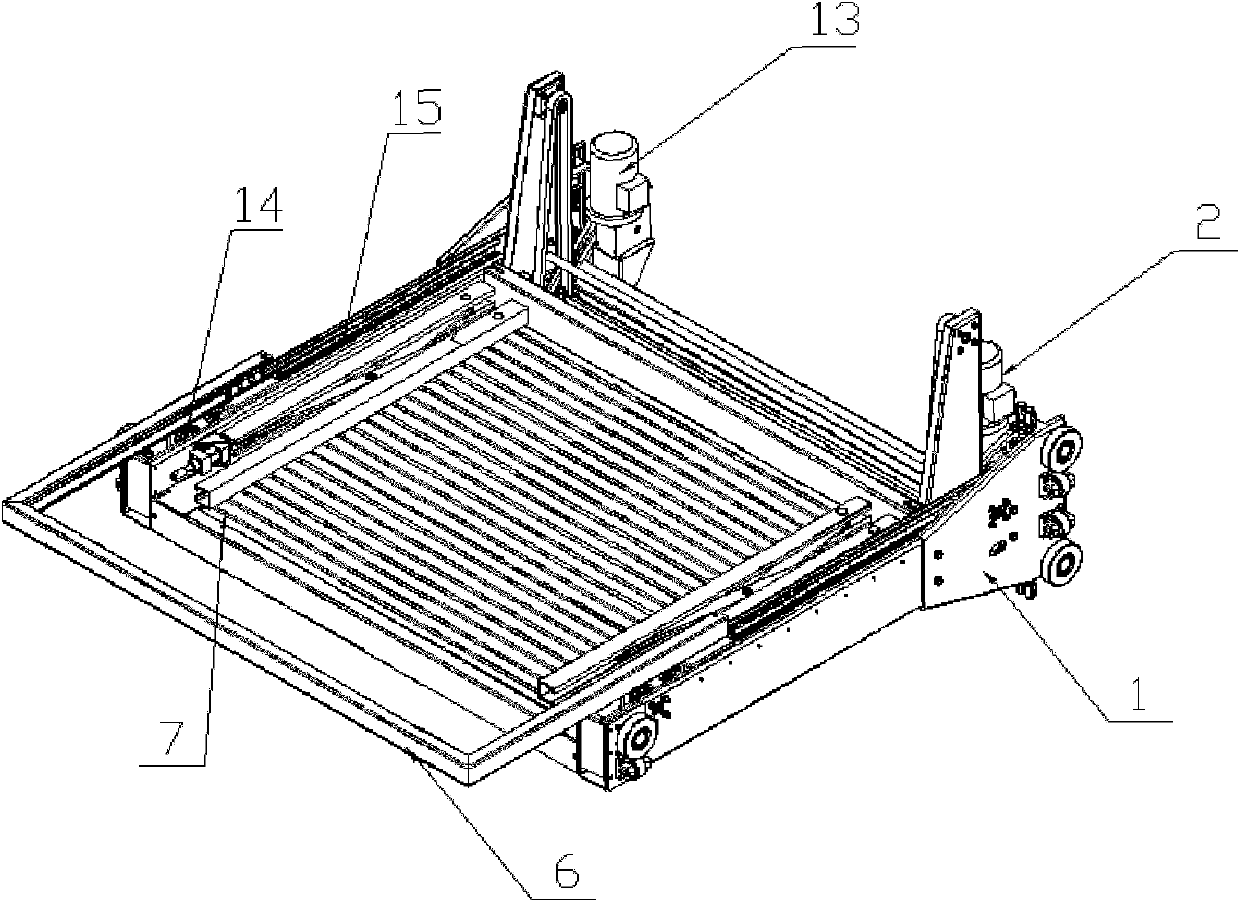

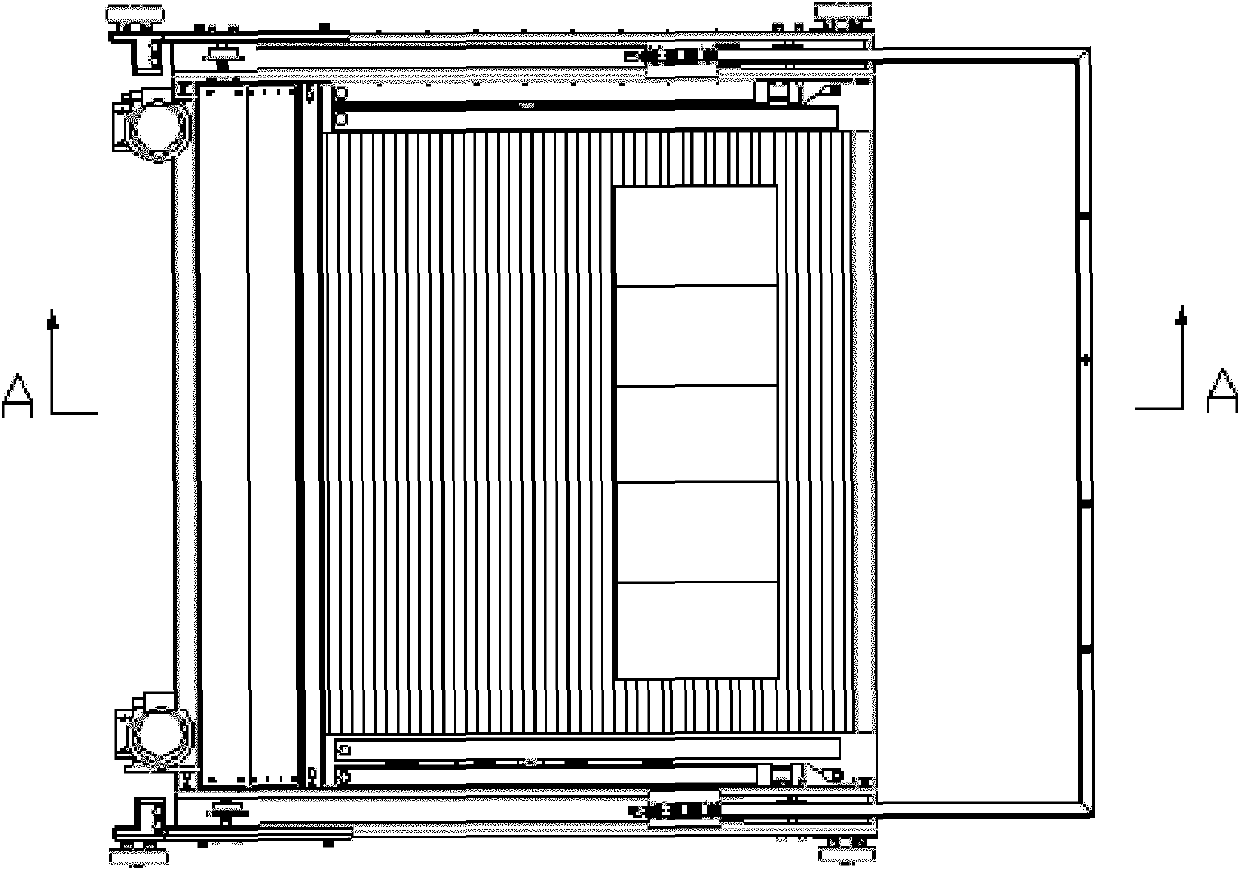

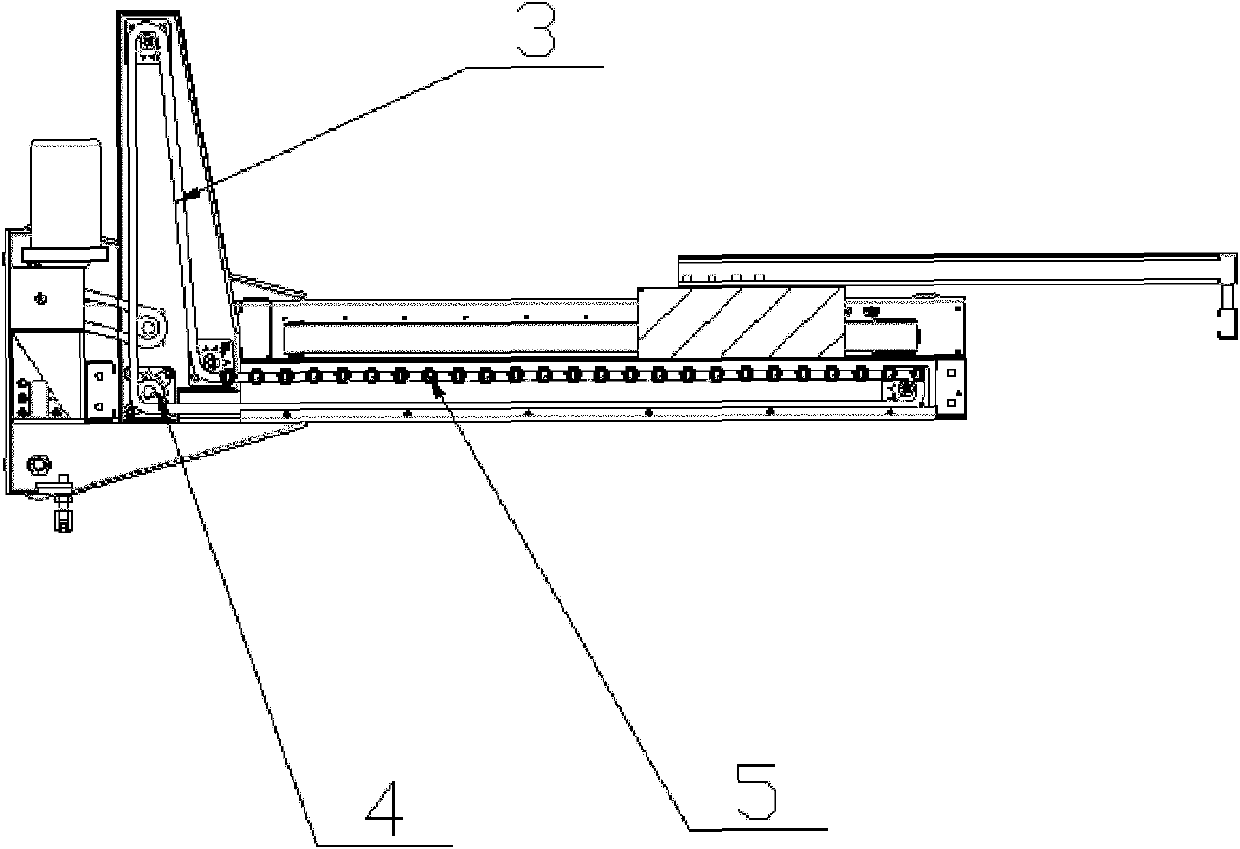

[0015] Embodiment: A kind of palletizing system, comprises fixed frame 1, rolling chain, rolling chain driving device 2, pull box bar 6 and clamping device, is based on using direction, is provided with a frame structure on fixed frame 1, and rolling chain drives Device 2 drives the rolling chain to perform telescopic movements along the frame structure of the fixed frame 1 from one end to the other. The two sides of the rolling chain perpendicular to its moving direction completely cover the two sides above the frame structure of the fixed frame 1, and the upper part of the fixed frame 1 is located on the vertical rolling chain Both sides of the moving direction are respectively fixed with a clamping mechanism symmetrically. The opposite sides of the two clamping mechanisms can move relative to each other along the direction of the vertical chain movement. On the lower side of the other end of the drawer rod 6, a protruding baffle is fixed. When in use, the open state of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com