Long-distance transport device for wind power generation blades

A technology for wind power blades and long-distance transportation, which is used in transportation and packaging, packaging, and food packaging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

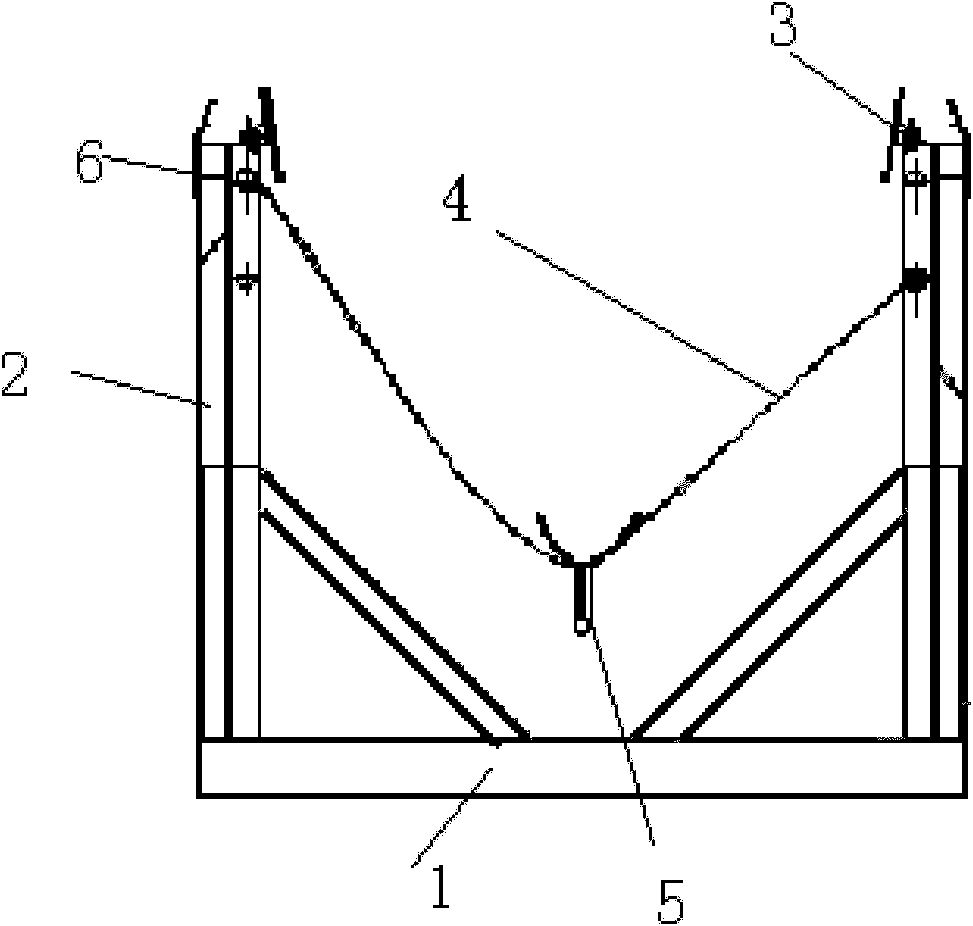

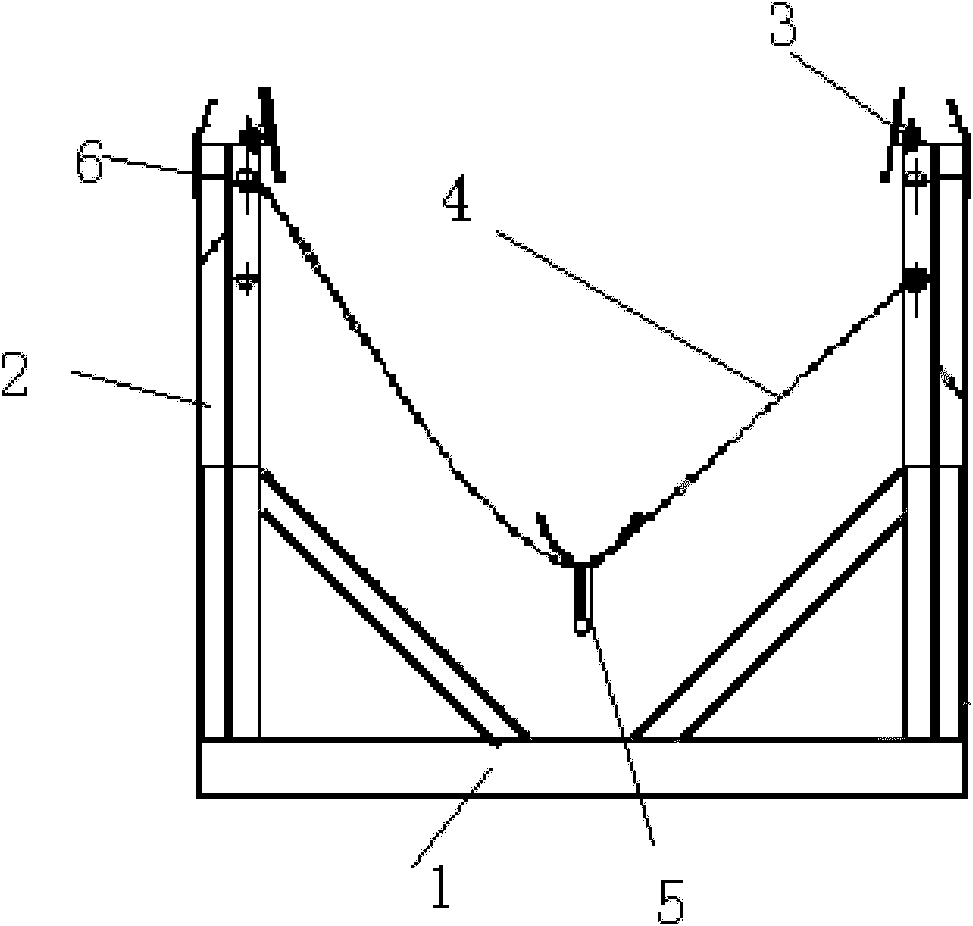

[0010] Depend on figure 1 It can be seen that the present invention includes: a blade support base 1; a blade support load-bearing rod 2 is respectively arranged on both sides of the blade support base; Both ends are fixed; the accompanying bracket 5 of the blade is arranged at the central bottom end of the sling 4;

[0011] A rotating bearing plate 3 wrapped with soft objects is also arranged inside the support load-bearing rod 2 .

[0012] The accompanying bracket of the present invention completely coincides with the blade during transportation, and it is suspended on the sling. When the blade shakes from side to side, because the bracket is movable, it can move on the blade sling, which prevents the bracket from being fixed on the base. The paint layer of the blade is crushed; when it is bumped up and down, the suspender is an elastic body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com