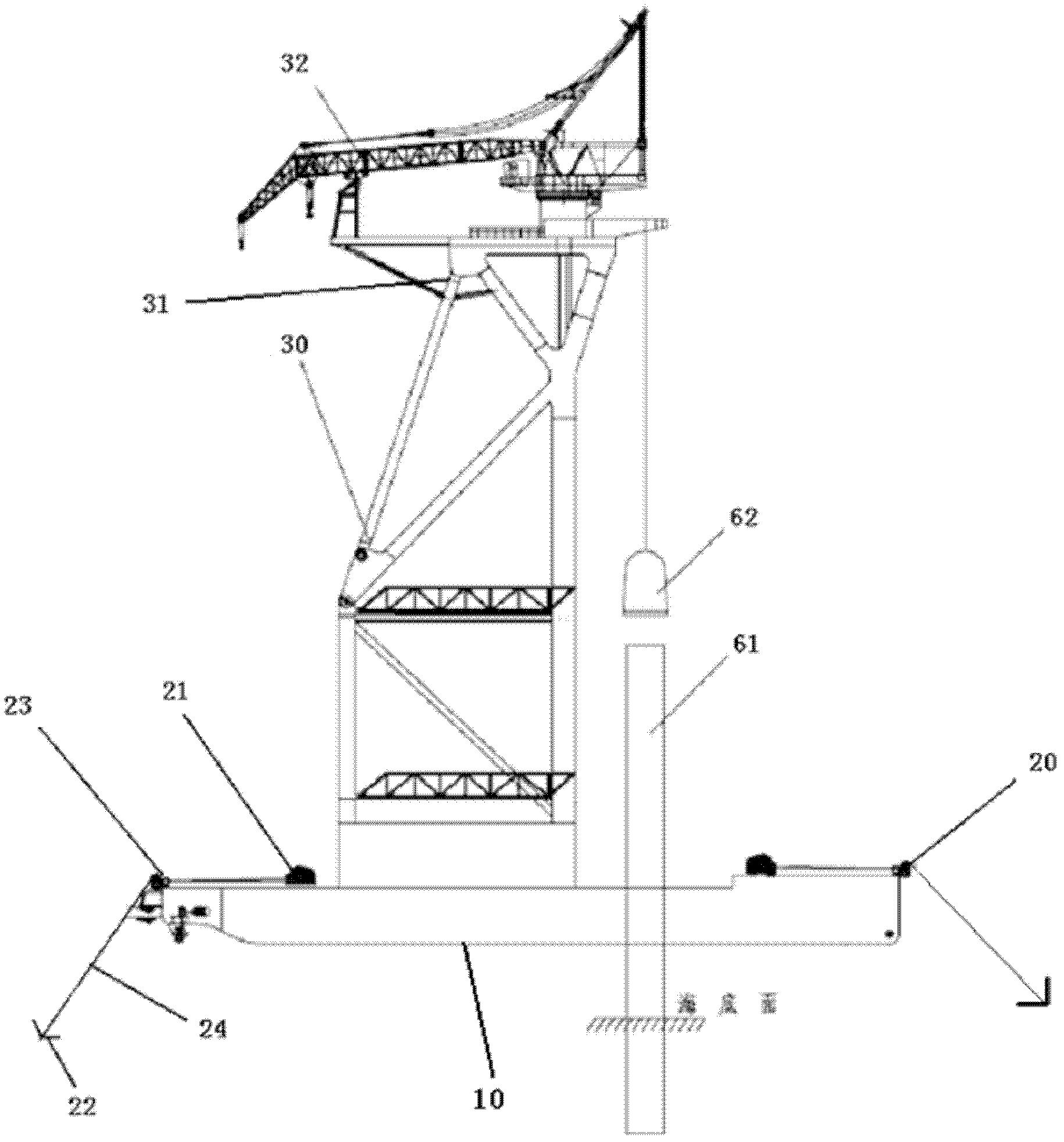

Self-propelled marine wind-power engineering operation boat capable of operating by sitting on sea bed

A technology for offshore wind power and work boats, which is applied to ship parts, ship construction, special-purpose ships, etc. It can solve the problems of low construction efficiency, small lifting capacity of cranes, and large lifting capacity of crane ships, and achieve anti-rolling Good performance and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Fan 50 is integrally installed, and the ship of the present invention equipped with fan 50 equipment arrives at the installation site, and the installation operation of fan 50 can be started. The operation ship equipped with fan 50 of the present invention arrives near the pile foundation that has been laid, and throws off the hull Fore and tail end work anchor 22, then tighten up or loosen the anchor cable 24 that casts an anchor so that the bow of the catamaran enters the pile foundation and is positioned correctly, so that the crane 30 sling center is aligned with the pile foundation centerline. Tighten each anchor to fix the ship's position, loosen the anchor cable, take back the upper and lower clamps, put down the sling of the crane 30 to make the fan 50 assembly fall on the pile foundation, and the installation is completed. After the fan assembly is installed, put away the anchors, start the full-turn thruster 12 at the tail, propel the front side and turn around...

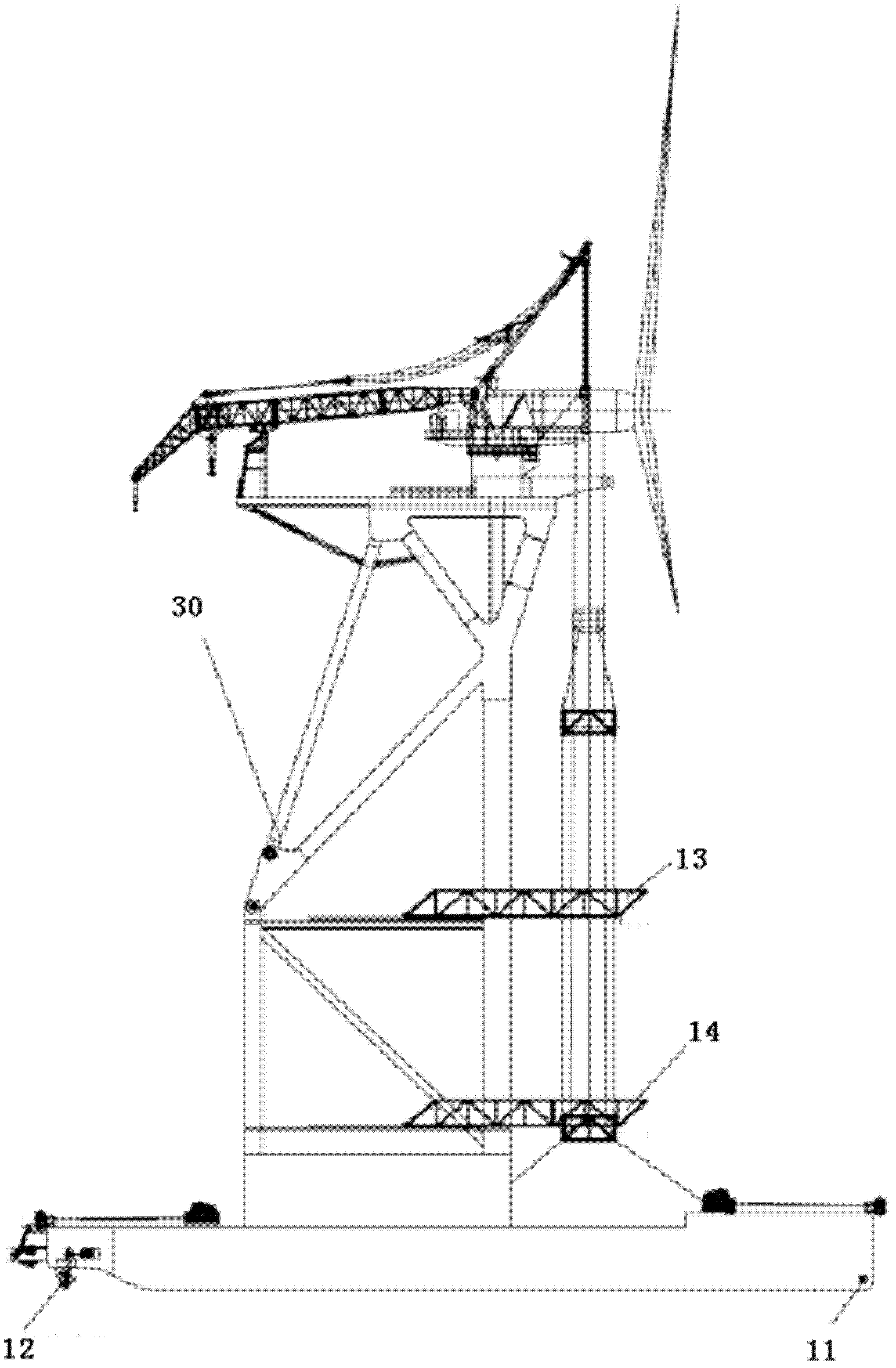

Embodiment 2

[0033] Modular installation fan or assembled fan, once the overall transportation and installation cannot be carried out due to the limitation of site conditions, and the split modular installation is adopted, it needs to use the full-slewing crane 32 to realize it. In the above situation, for example, the installation site is far away from the port wharf. After economical argumentation, it is found that it is not as good as transporting multiple (10 or more) fan assemblies at a time by a transport barge to transport one complete machine each time from the wharf to the construction site. It is economically more efficient to install all components modularly at the fan installation.

[0034] The way to assemble the wind turbine 50 is to use the azimuth crane 32 on the crane 30 to carry out.

[0035] First throw out the bow and tail working anchors to fix the ship's positioning. Start the full-slewing crane 32 to rotate the crane 30 and the lifting arm to the barge equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com