Building process for ship central control room

A centralized control room and process technology, applied in shipbuilding, ship components, ships, etc., can solve the problems of long integrity work cycle, restriction of shipyard shipbuilding capacity, and long construction time, so as to achieve easy quality assurance, improve shipbuilding efficiency, The effect of convenient welding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

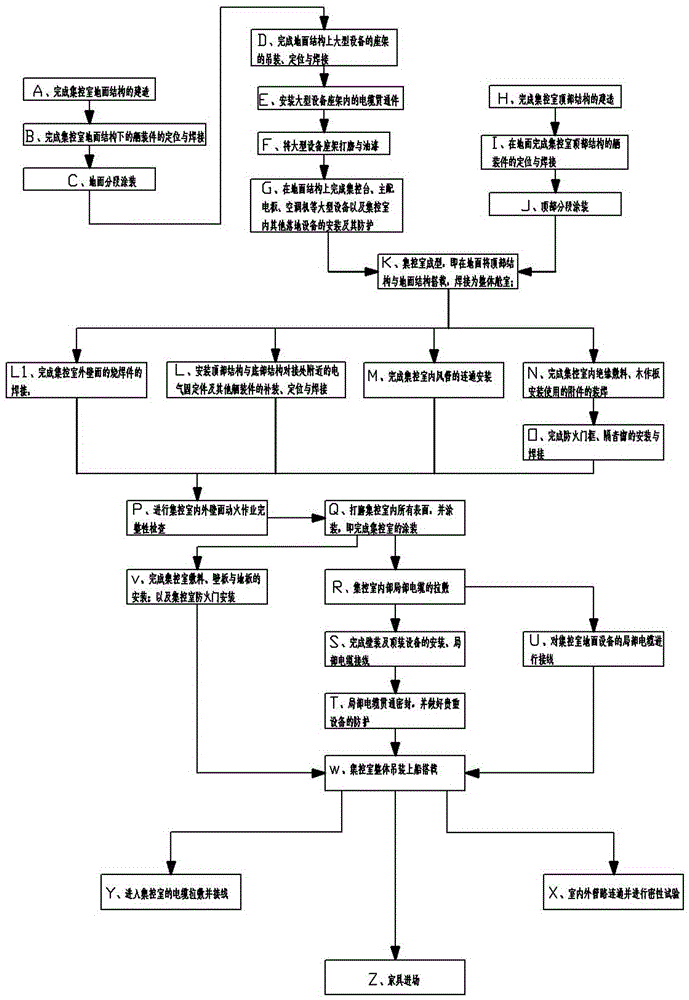

[0037] figure 1 , a construction process of a centralized control room of a ship. Firstly, the ground structure and the top of the centralized control room are respectively completed. Then, complete the following operations in turn on the ground structure: positioning and welding of the outfitting parts under the ground structure, mainly electrical fixtures; painting of the ground segments; hoisting and positioning of large equipment mounts on the ground structure of the centralized control room and welding; install cable penetrations in the large-scale equipment frame; polish and paint the large-scale equipment frame, and complete large-scale equipment such as centralized control consoles, main switchboards, air conditioners, and other floor-standing equipment in the centralized control room on the ground structure The installation is protected by a protective device, which can be a triple protective device from the inside to the outside consisting of a film, a three-proof c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com