Flange spot welding clamp for automobile exhaust recirculation cooling system diffuser

A waste gas recirculation and cooling system technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problem that the positioning accuracy cannot meet the requirements, affect the installation accuracy of the flange and the diffuser shell, and the shape and structure of the diffuser are small and other problems, to achieve reliable clamping, facilitate spot welding operations, and ensure the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

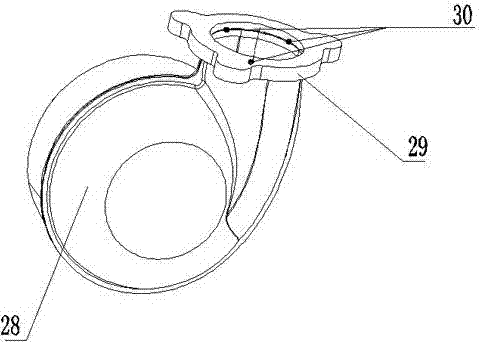

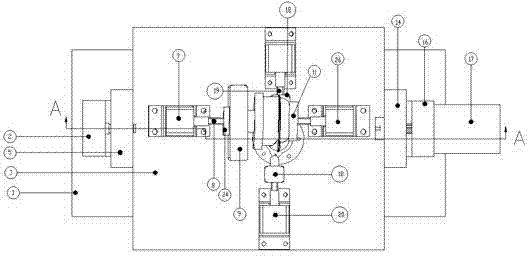

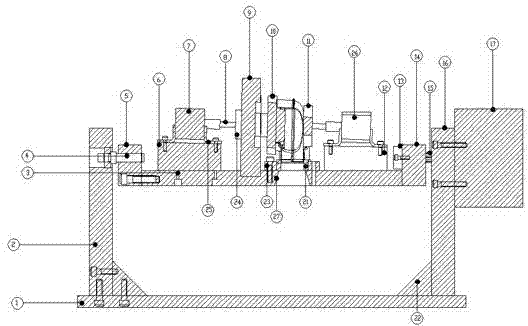

[0010] See figure 2 and image 3 , the present invention comprises a base plate 3, a support frame, a rotary cylinder 17 and a workpiece positioning clamping device, wherein the support frame comprises a support plate 1, and support blocks 2, 16 are installed at both ends of the support plate 1, and the support plate 1 and the support block 2, 16 are strengthened and connected by reinforcing ribs 22, and the rotary cylinder 17 is fixed on the lateral right end support block 16 of the support frame, and the two ends of the bottom plate 3 are installed on the support blocks 2, 16 through the coupling blocks 5, 14, and the coupling blocks 14 is connected and fixed with the output transmission shaft 15 of the rotary cylinder 17, the coupling block 5 is installed on the support block 2 through the support shaft 4, the flange positioning boss 23 is fixed on the bottom plate 3, and the flange positioning boss 23 is provided with a flange The inner hole with matching shape, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com