Automatic feeding medium-frequency diathermic furnace for forging automobile half axle

An intermediate frequency diathermy furnace and automatic feeding technology, applied in forging furnaces, furnaces, furnace types, etc., can solve the problems of coarse grains of the half shaft, oxidation and burning of the workpiece, and scrapping of the half shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

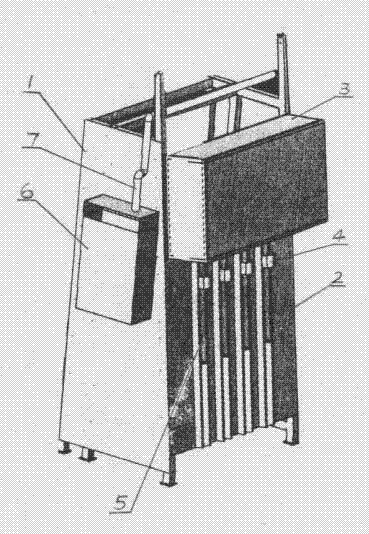

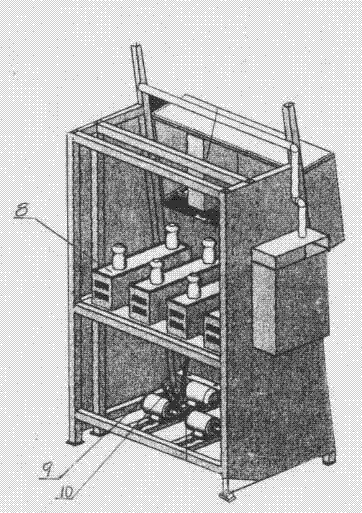

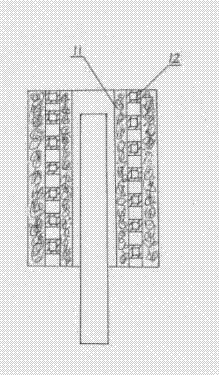

[0014] Such as figure 1 The shown intermediate frequency diathermy furnace includes a vertical frame 1, the front is a slightly inclined facade 2, and the upper end of the facade is an intermediate frequency diathermy furnace. In this embodiment, there are four groups of furnaces, and a box is used outside 3 wrapped, figure 1 The visible part also includes a group of semi-axis bars 5 to be heated held by a set of clamps 4. The clamps 4 are fixedly connected to the chain transmission device on the back to form a bar feeding mechanism. Each induction furnace corresponds to a bar The material feeding mechanism is used to vertically send the semi-axis bar to be heated into the furnace, or the heated bar is withdrawn. There is also a water tank 6 attached to the side of the frame 1. The water tank is filled with water for cooling and heating pipes. Pipeline 7 leads in the conduit of each body of heater. Such as figure 2 The device visible from the rear view includes a group of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com