Dangerous waste microwave pyrolytic incineration equipment

A hazardous waste and microwave technology, applied in the field of environmental protection, can solve the problems of difficult disposal of hazardous waste, high processing cost, cumbersome processing process, etc., and achieve the effects of easy market popularization, simplified processing and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

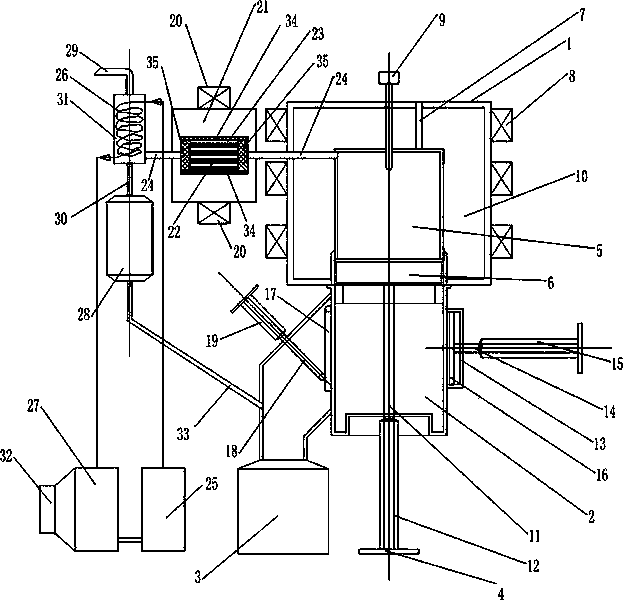

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] refer to figure 1 As shown, the hazardous waste microwave pyrolysis incineration equipment in this embodiment includes a microwave pyrolysis box 1, a treatment chamber 2, a filter device, a cooling system, a control system for automatically controlling the actions of various components, a collection device 3 and a frame 4. A plurality of microwave heating systems 8 are installed on the outside of the microwave pyrolysis box 1, and microwave heating is adopted. It has a closed pyrolysis chamber 5, and the pyrolysis chamber 5 in the treatment chamber 2 is sealed and communicated, and the interior of the treatment chamber 2 is equipped with a lift Formula holding platen 6. On each side of the pyrolysis chamber 5, an opening is provided on the side communicating with the treatment chamber 2, and when the lifting type material holding platen 6 moves to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com