Peanut sheller

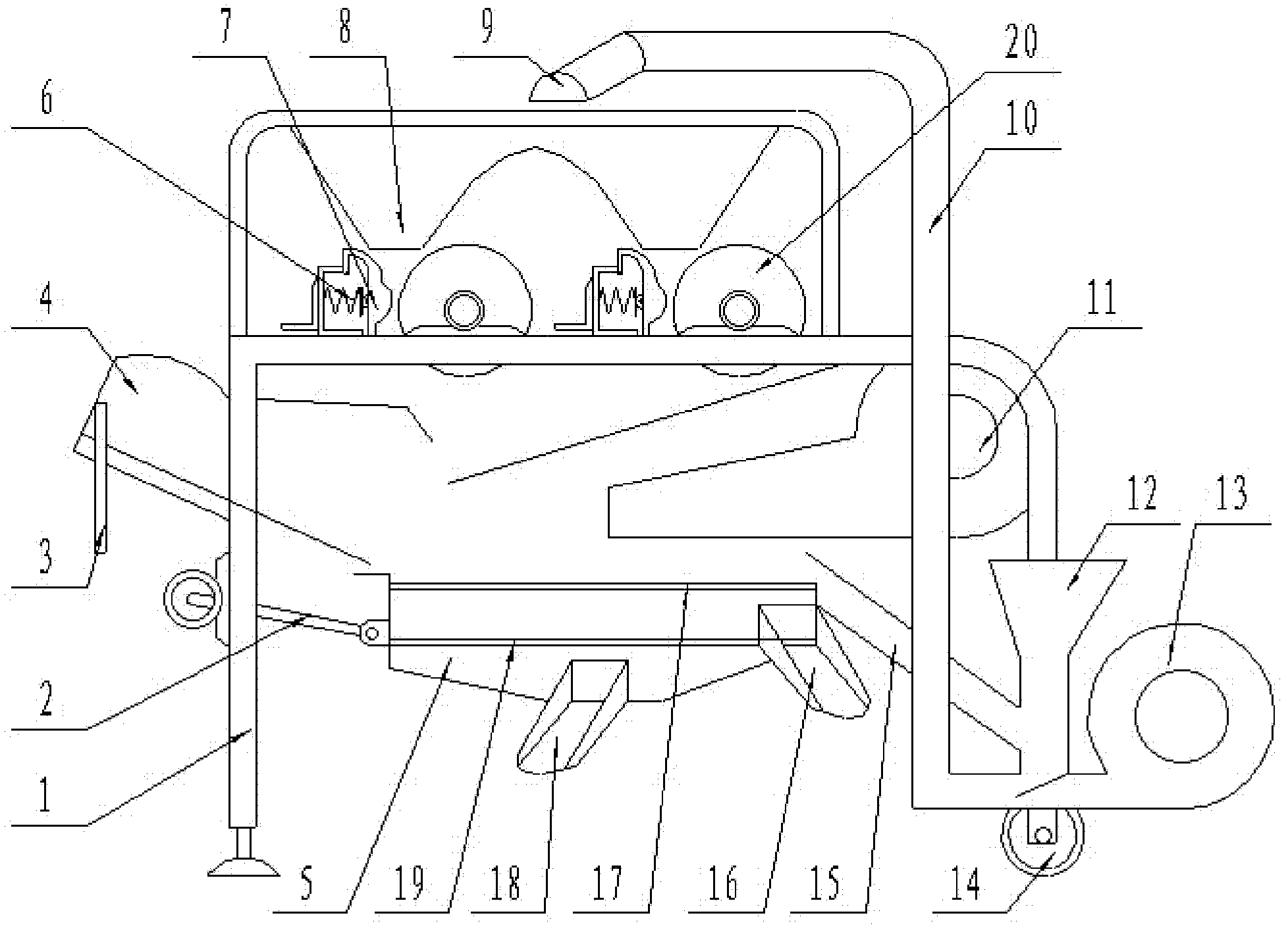

A sheller and peanut technology, which is applied in the field of agricultural machinery, can solve the problems of high breakage rate and damage rate, damaged seed coat and germ, and can not meet the requirements of peanuts, and achieves the effect of breaking and light damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

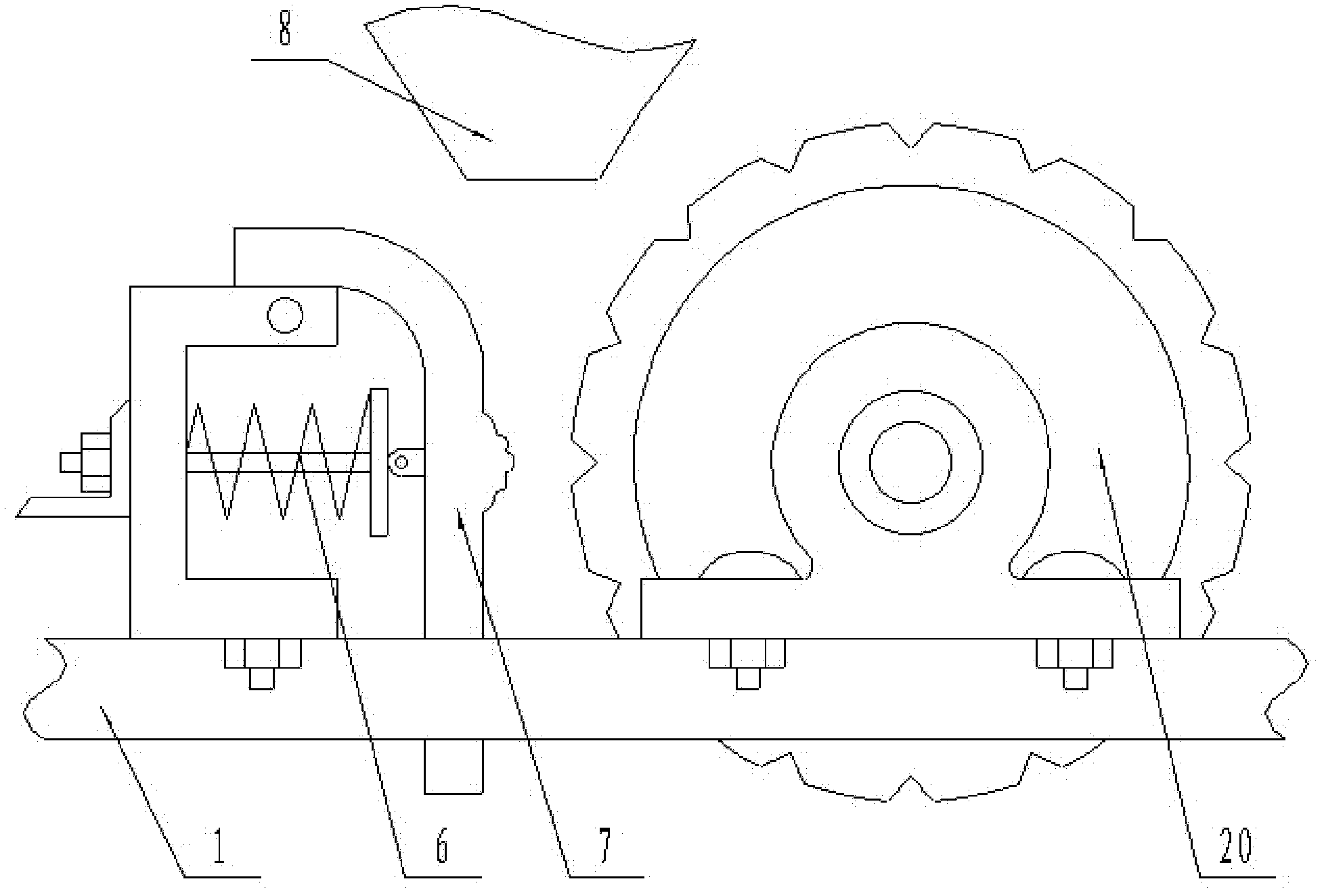

Method used

Image

Examples

Embodiment 1

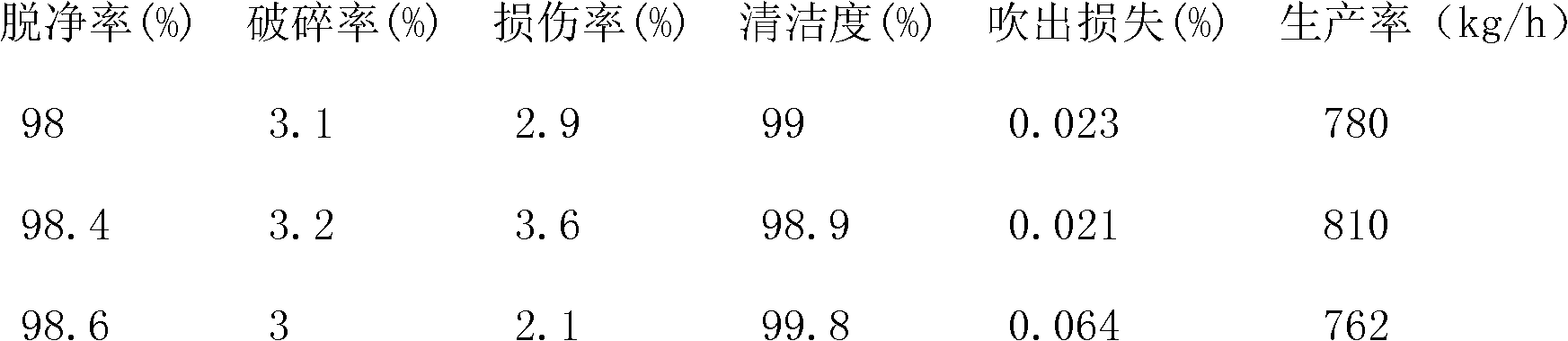

[0031] Take peanuts with length, width, and height of 30.1mm, 13.4mm, and 14.9mm, respectively, and 9% water content as raw materials, and the horizontal distance between the upright rubber plate and the rubber roller is the peeling gap, which is 12.5mm. The experimental results are as follows:

[0032]

[0033] From the above experimental results, it can be seen that when the peanut shelling gap is 12.5mm, the average removal rate is 98.3%, the average breaking rate is 3.1%, the average damage rate is 2.9%, and the average cleanliness is 99.2%. The average blowing loss is 0.036%, and the average productivity is 784kg / h.

Embodiment 2

[0035] Take large peanuts with length, width, and height of 43.5mm, 15.2mm, and 18mm, respectively, and a moisture content of 7% as raw materials. The horizontal distance between the upright rubber plate and the rubber roller is the peeling gap, which is 13.5mm. The experimental results are as follows:

[0036]

[0037] From the above experimental results, it can be seen that when the shelling gap is 13.5mm, the average removal rate is 97.8%, the average breaking rate is 6%, the average damage rate is 3.5%, and the average cleanliness is 96.8%. The average blowing loss is 0.065%, and the average productivity is 620kg / h.

[0038] According to the experimental data, it can be known that the peeling quality of the present invention is relatively high, which can completely replace manual peeling, and meet the requirements of seeding, export, etc.; mechanized peeling greatly improves production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com