Cane harvester

A harvester and sugarcane technology, which is applied in the field of sugarcane harvester and agricultural machinery, can solve the problems of restricting the development of sugar industry, high labor intensity, low production efficiency, etc., and achieve the effects of light weight, reduced head breaking rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

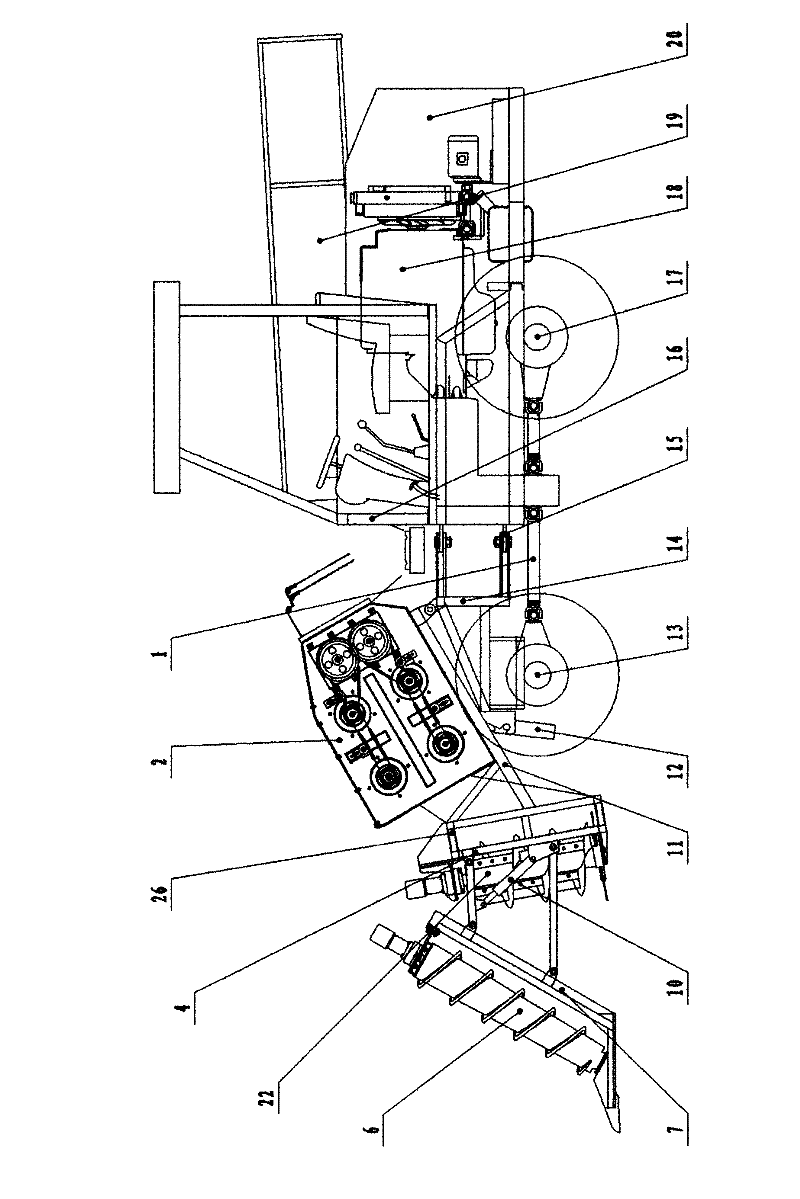

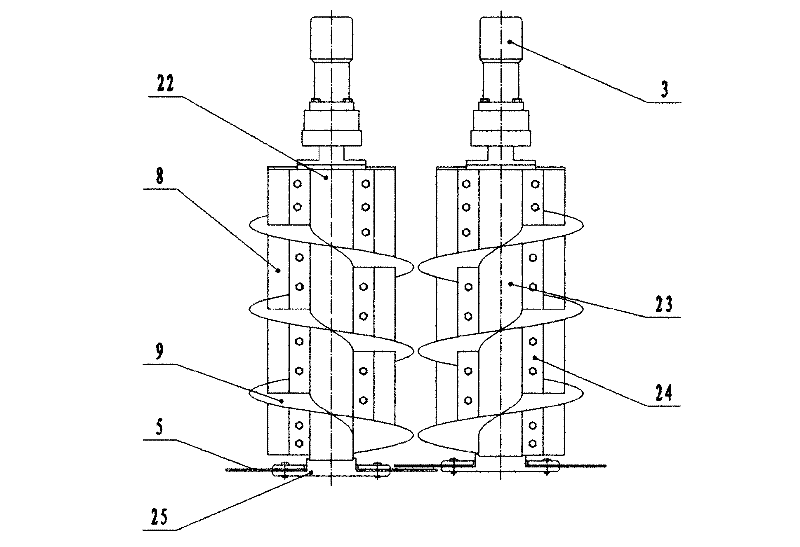

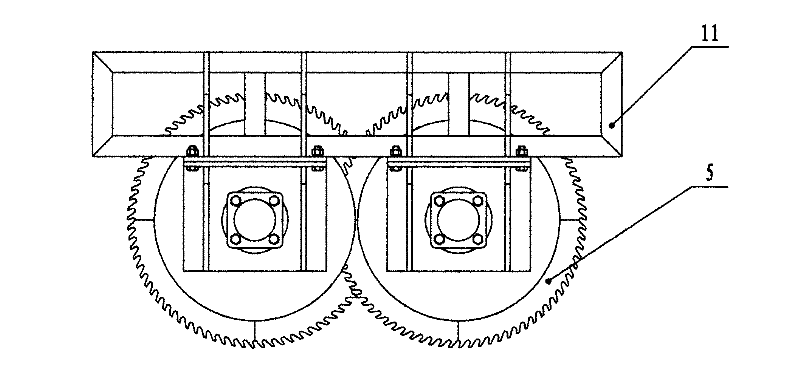

[0023] Refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Frame chassis assembly 1 is assembled by internal combustion engine 18, gearbox, front drive axle 13, rear drive axle 17, front frame 14, rear frame 15 and drive wheels, so that it can complete the waist turning of the whole machine , Allowing the sugarcane harvester to get a smaller turning radius during operation. The cab assembly 16 is assembled by the seat and the operating mechanism. In addition to providing walking power for the whole machine, the internal combustion engine 18 also provides power for the oil pump, cylinder, and hydraulic motor of the hydraulic system 20. The front part of the T-shaped lifting support frame assembly 11 is mounted on the front drive axle 13 of the frame chassis assembly 1 and connected with the lifting cylinder 12 mounted on the frame chassis assembly 1, and its rear part is connected with the frame chassis Hinge connection on assembly 1. The header assembly 4 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com