Cutting device for sugar cane harvester

A technology of cutting mechanism and harvester, which is applied in the direction of harvester, agricultural machinery and implements, etc. It can solve the problem of increased rate of broken heads, falling in front of the harvester, or falling on the cutter head and blade at a certain angle Problems such as improving and reducing the sugar yield, to achieve the effect of prolonging the service life, reducing the broken head rate, and ensuring the sugar yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

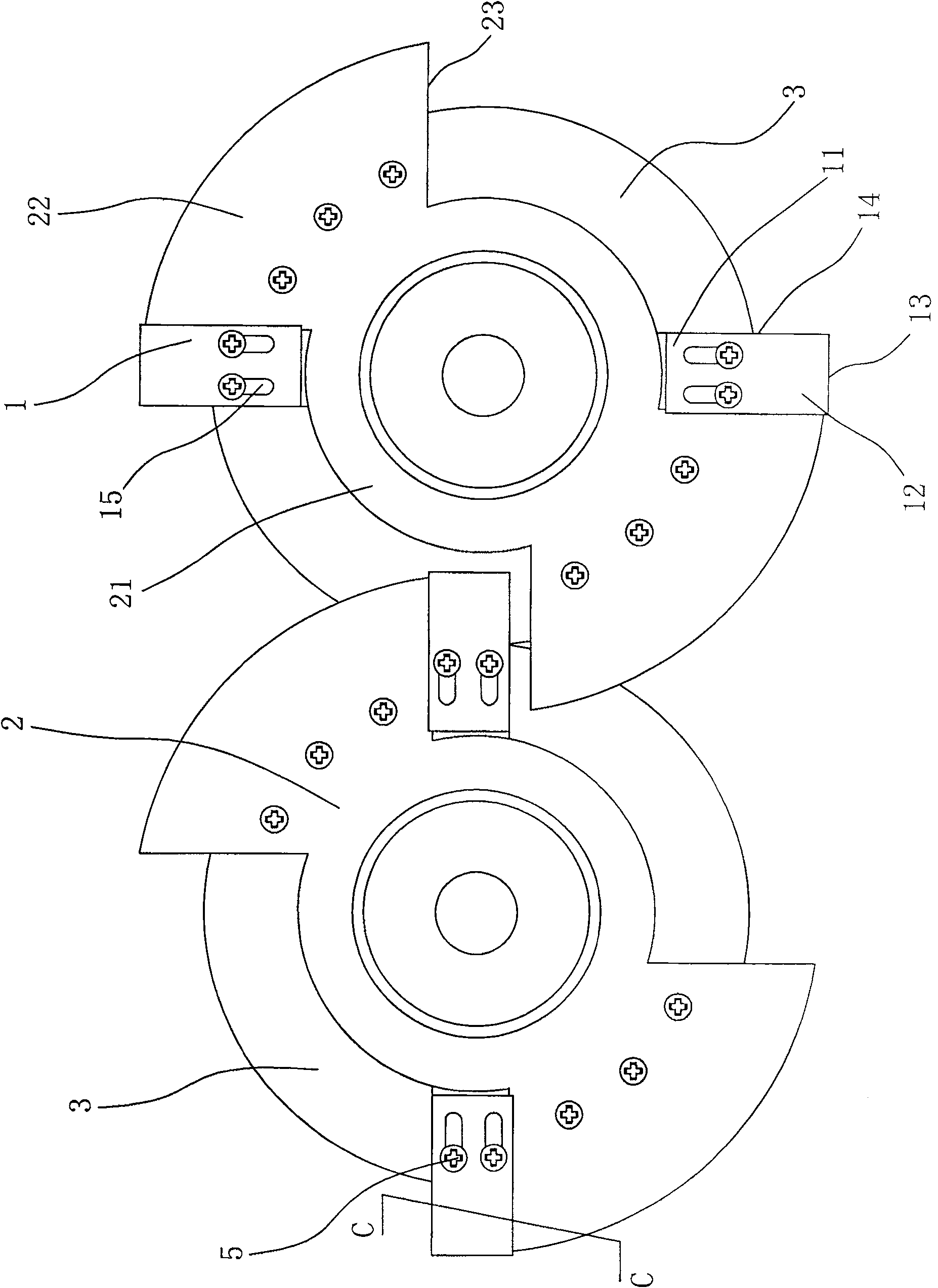

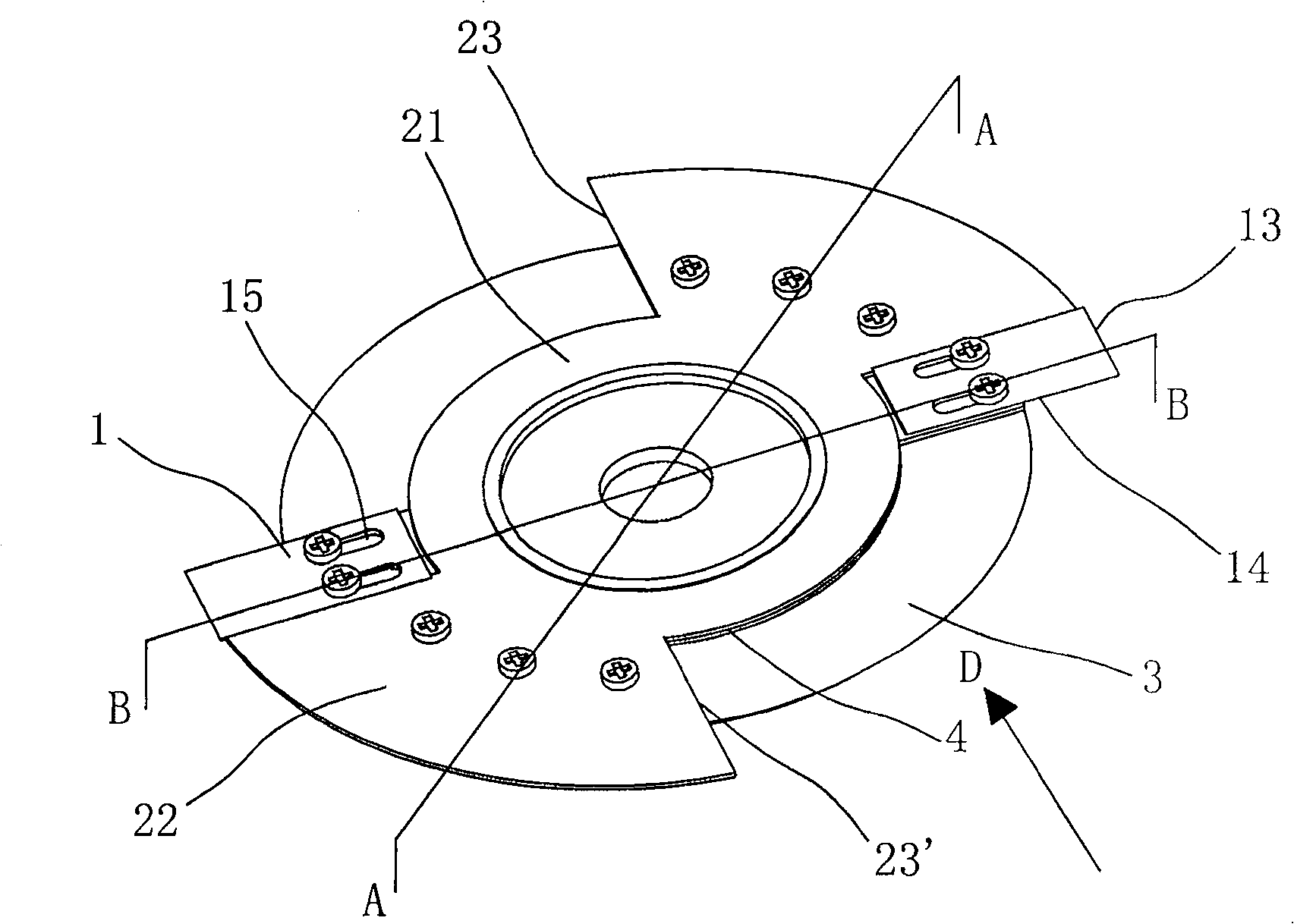

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

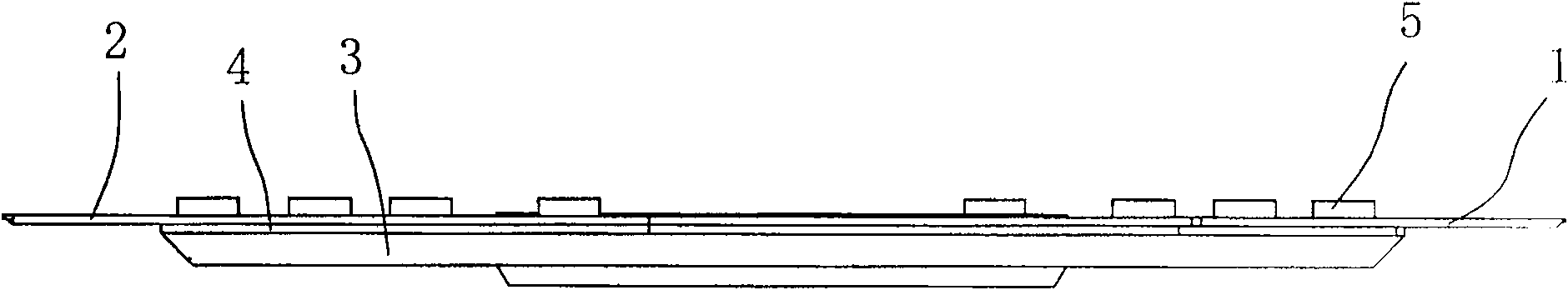

[0024] as 1 to Figure 7 As shown, the cutting mechanism of the sugarcane harvester includes left and right cutterheads 3, blades 1, supporting plates 2 and backing plates 4 with the same structure.

[0025] in,

[0026] The cutter head 3 is driven by an external force, for example, a rotating shaft (not shown) driven by an intermeshing gear set (not shown) connected to a motor shaft (not shown) To drive, the rotating shaft is fixed on the rotating hole 31 provided at the center of the cutter head.

[0027] The backing plate 4 is fixed below the cutterhead 3. In this embodiment, the middle part of the backing plate 4 is a circular ring concentric with the cutterhead 3, and the outside of the backing plate 4 is a sector extending outward from the circular ring. And the outer end edge of backing plate 4 coincides with the outer end edge of cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com