Movable contact for switching

A technology of moving contacts and switches, applied in the field of improvement of movable contacts, can solve the problem of frequent occurrence of poor recovery, and achieve the effect of avoiding poor recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

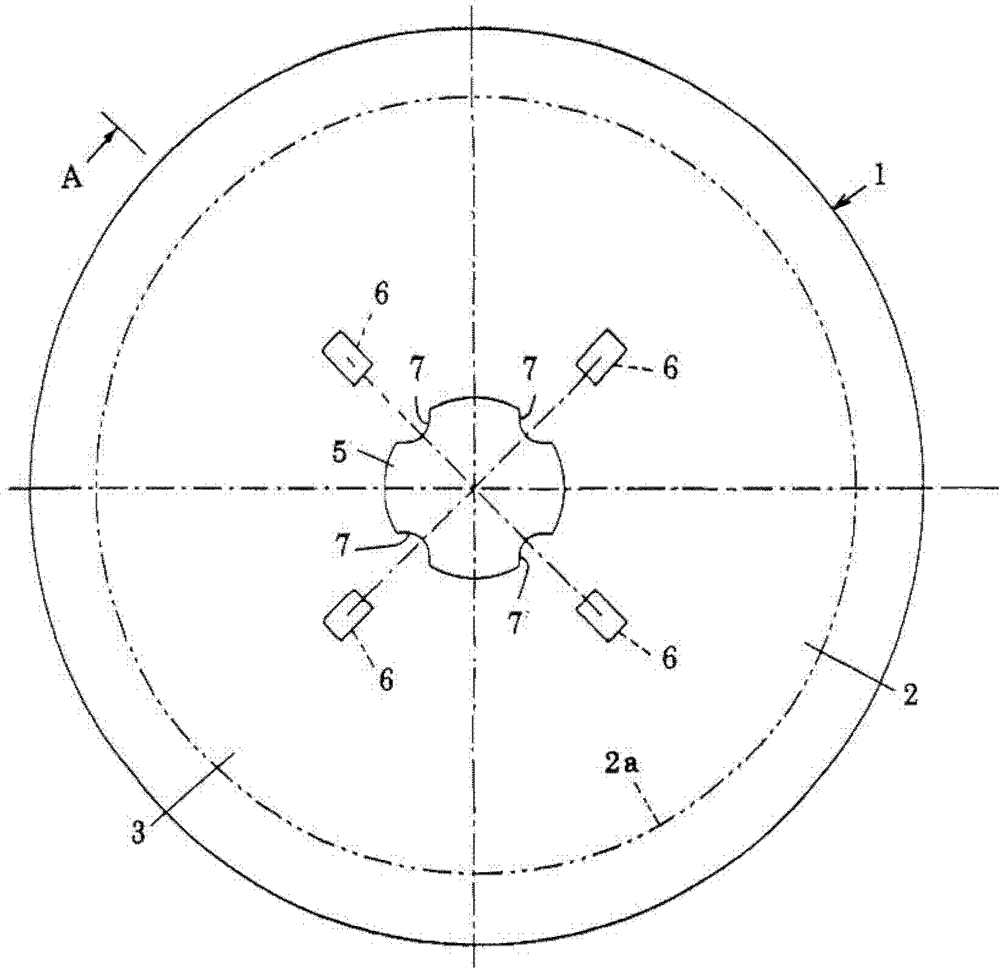

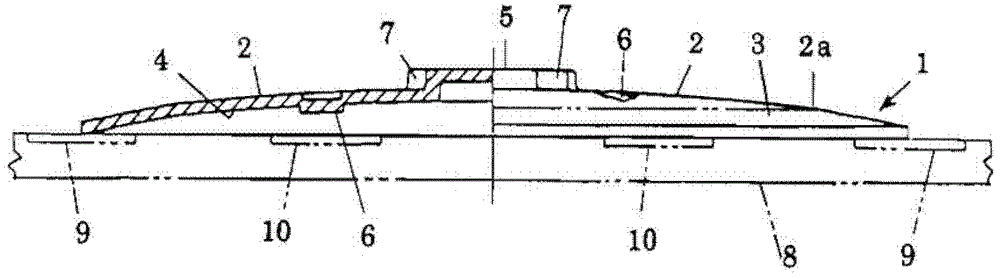

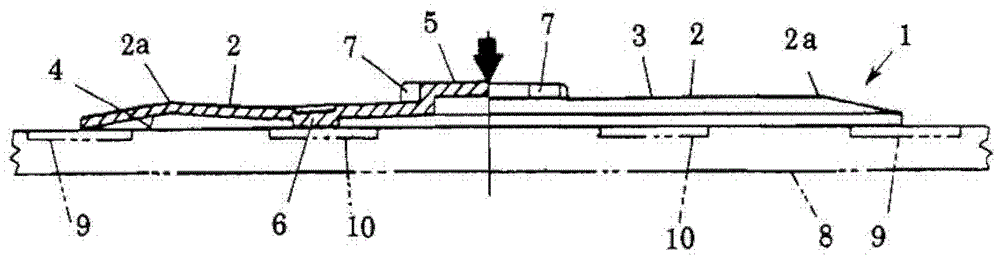

[0029] exist figure 1 as well as figure 2 Among them, the movable contact 1 for a switch according to the present invention is configured as a contact piece 2 that can be reversed by bending a substantially circular conductive spring material into a dome shape. The conductive spring material is a round silver-plated or nickel-plated stainless steel plate with a thickness of about 0.04-0.1 mm, and if it is an operation key of a mobile phone, its size is about 3-6 mm in diameter. In addition, the contact piece 2 is not limited to a circular conductive spring material, and can also be made of an appropriate shape according to the assembly object, such as an oval, oval, rhombus, and rectangular conductive spring material, and a diamond-shaped, rectangular conductive spring material. The corner part is made of conductive spring material in the shape of a circular arc or a straight line.

[0030] The contact piece 2 has a dome-shaped, for example, truncated conical bulging portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com