Copper wire pneumatic compression transmission device

A pneumatic compression and transmission technology, applied in the direction of electrical components, circuits, conductor/cable insulation, etc., can solve the problems of inability to ensure straight line transmission, easy twisting and deformation of copper wires, etc., achieve high efficiency, ensure quality, and fast lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

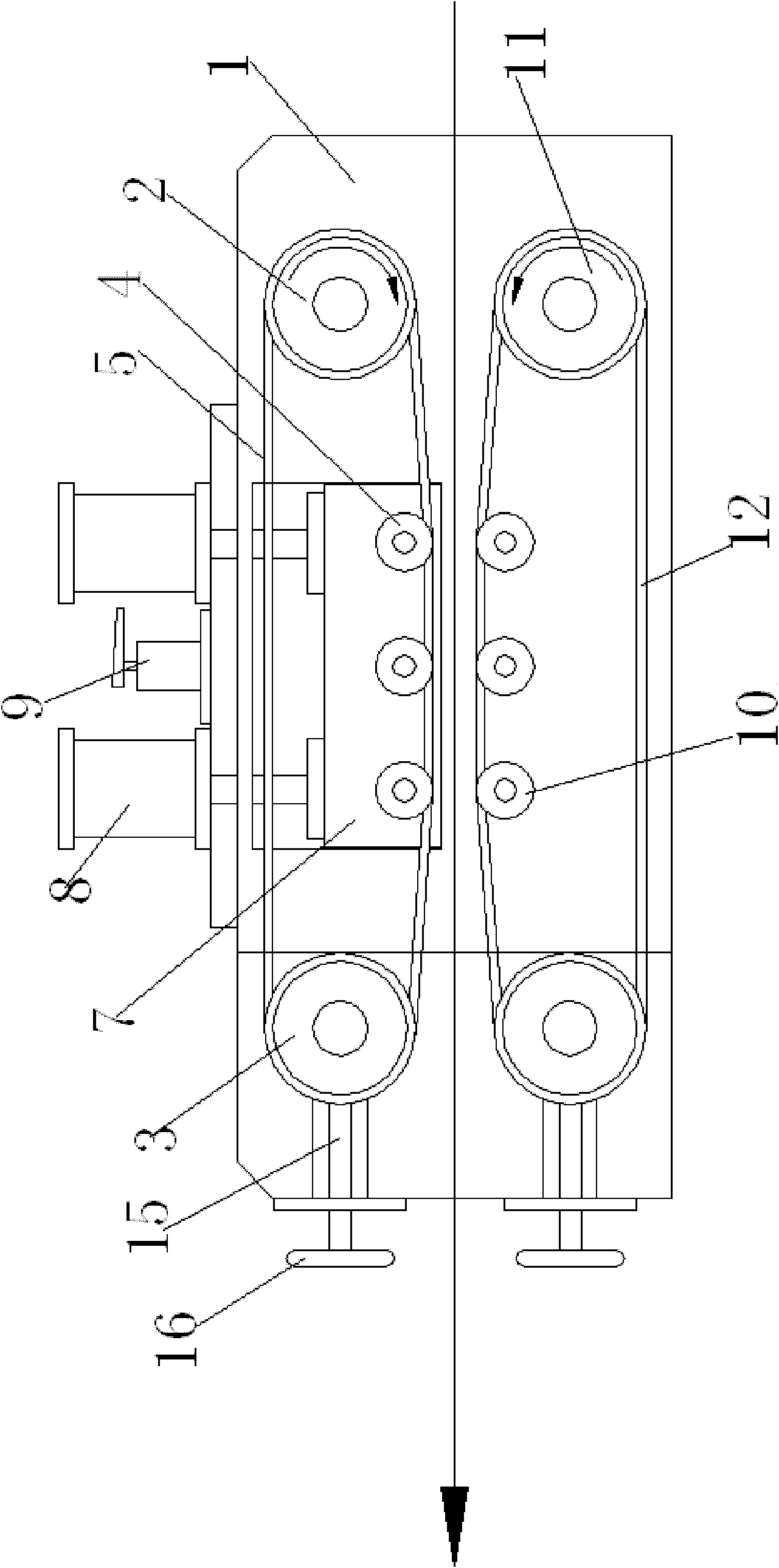

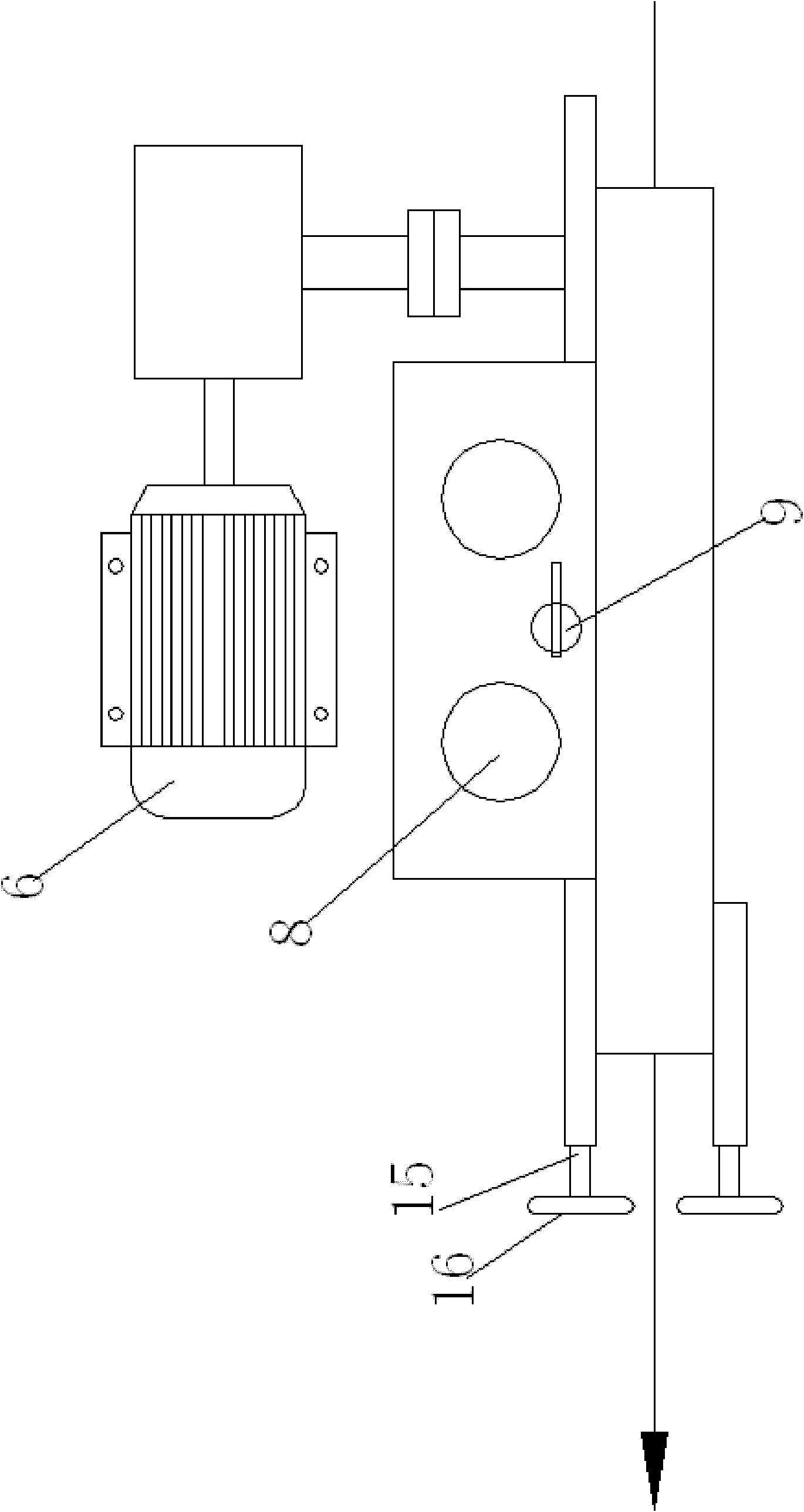

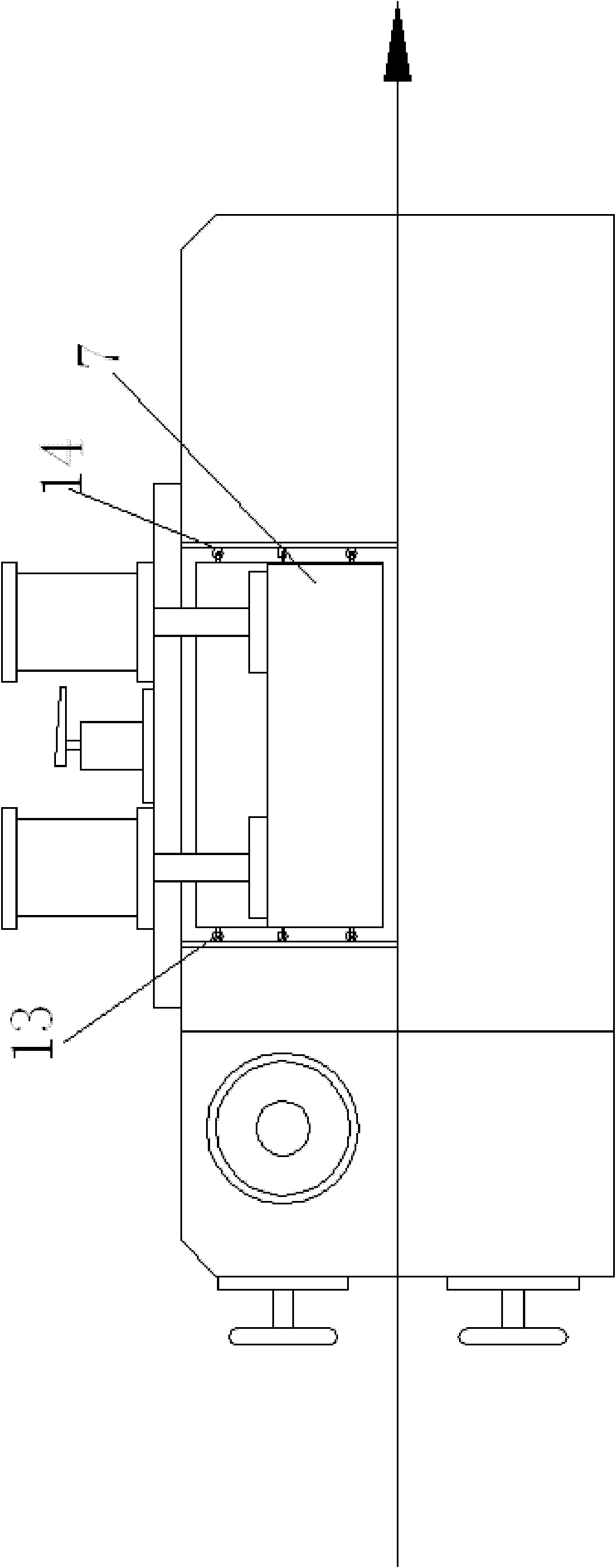

[0013] Reference Figure 1 to Figure 3 A copper wire pneumatic compression transmission device is shown, which includes a main body 1, an active synchronous belt wheel set and a passive synchronous belt wheel set arranged on the main body 1. The active synchronous belt wheel set includes an upper driving wheel 2 and an upper driven wheel 3. The upper driven wheel group 4 and the upper conveyor belt 5, the driving wheel is driven by the motor 6, the upper driven wheel group 4 is arranged on the lifting plate 7, the lifting plate 7 is connected with the push rod of the cylinder 8 arranged on the top of the main body 1, the main body 1 An air pressure adjustment switch 9 for controlling the contraction of the push rod of the cylinder 8 is provided on the upper part. The passive synchronous belt wheel group includes a lower driven wheel group 10, two lower driven wheels 11 and a lower conveyor belt 12. The lower driven wheel group 10 is fixed on the main body 1.

[0014] On the basis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap