Shaft sealing device with magnetic fluids

A magnetic fluid and shaft sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem of reducing the pressure bearing capacity of the magnetic fluid shaft seal, increasing the radial size of the annular seal gap, and reducing the bearing pressure of the magnetic fluid shaft seal. It can solve the problems such as reducing the value of the installation process, reduce the uneven distribution, and reduce the accuracy of the coaxiality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

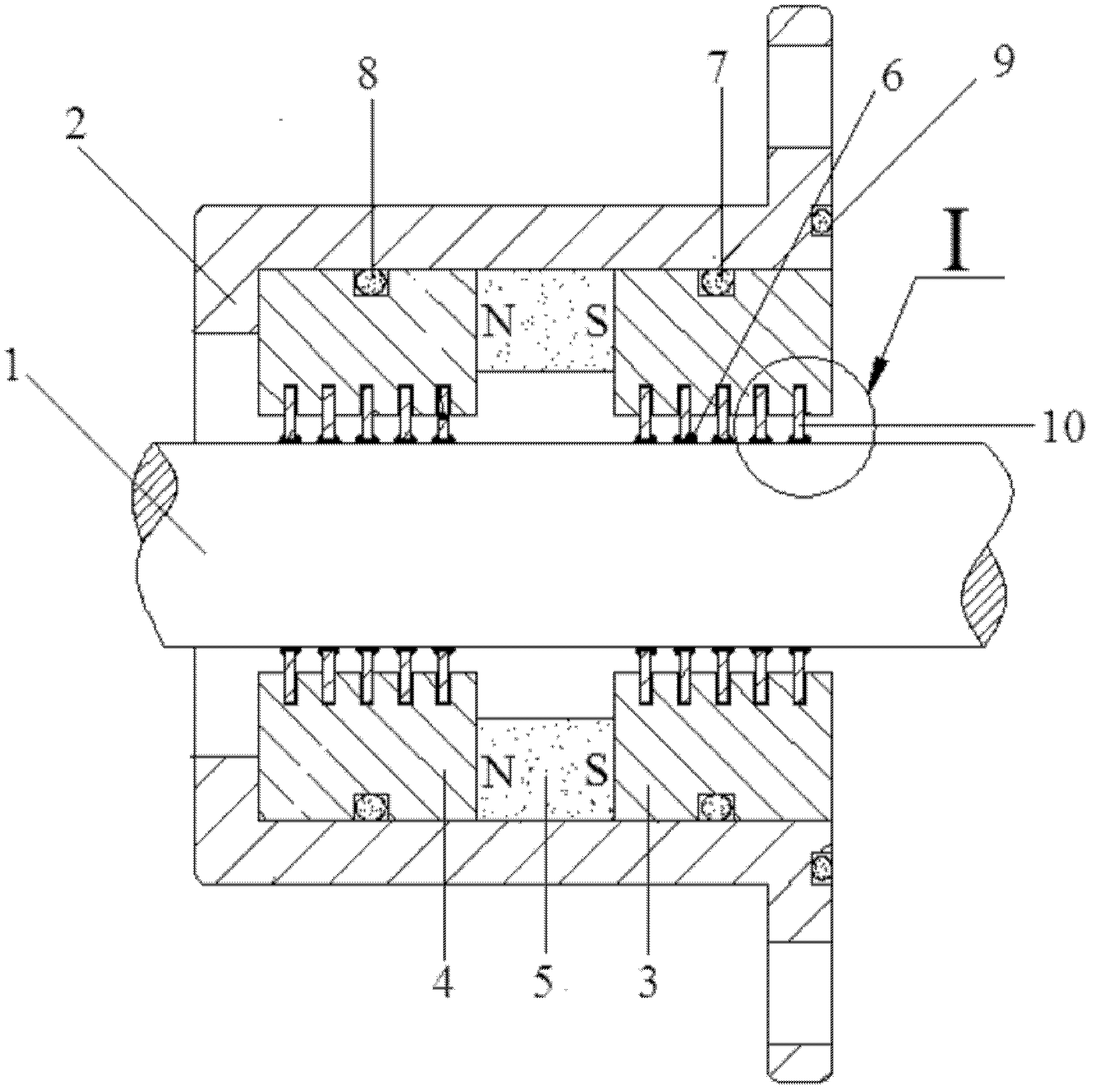

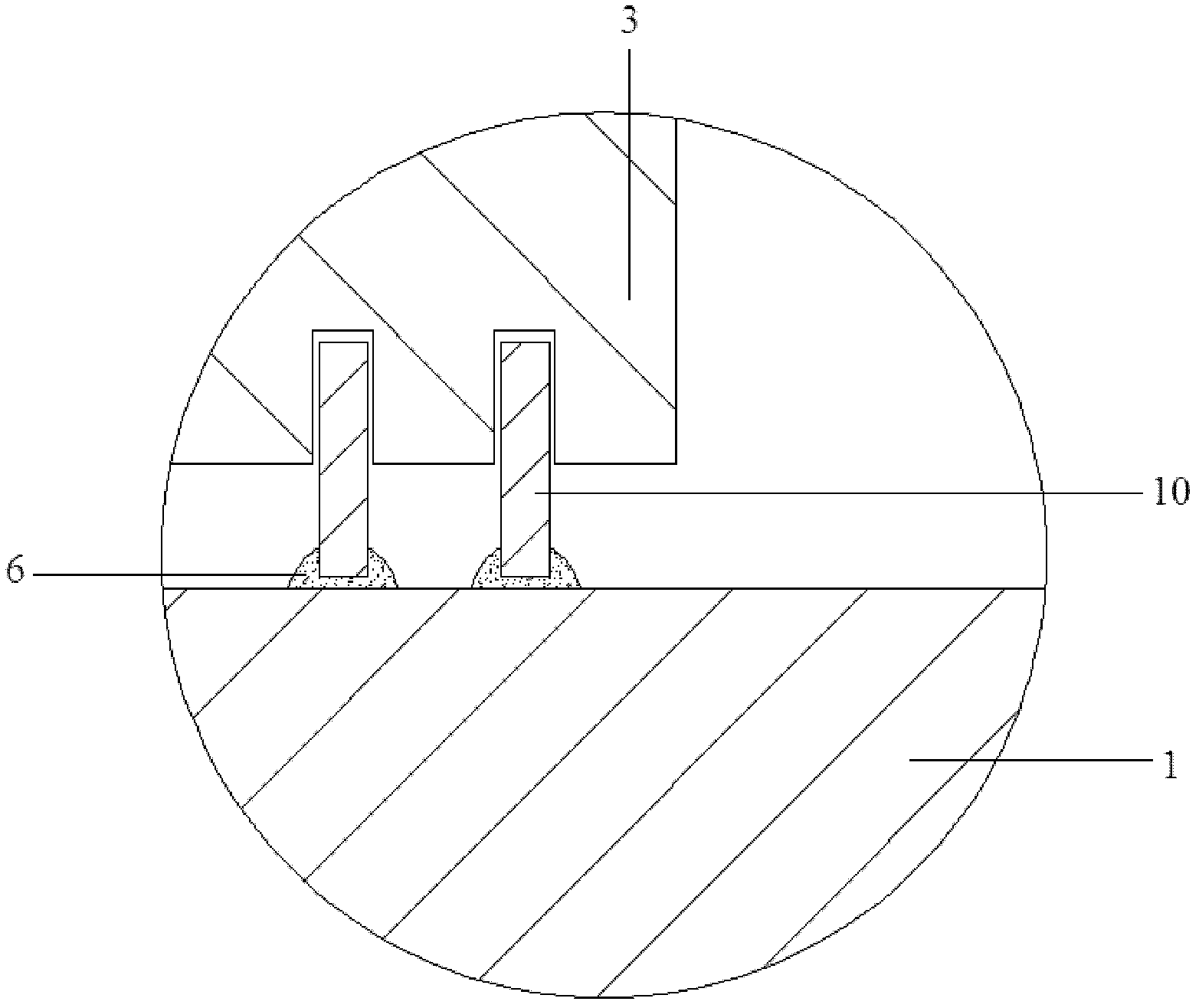

[0023] A magnetic fluid shaft seal device, such as figure 2 As shown, it is a magnetic fluid shaft sealing device for sealing water on a water pump. The device is mainly composed of a rotating shaft 1, a non-magnetic metal shell 2, a magnetic pole, a permanent magnet 5, a magnetic fluid 6, a rubber ring and sealing pole teeth The ring consists of 10. Among them, such as Figure 4 As shown, each magnetic pole is ring-shaped and composed of two semi-annular magnetic poles. Sealing pole teeth are processed on the inner circumference of the magnetic poles. The two magnetic poles are the first magnetic pole 3 and the second magnetic pole 4 respectively; the three rubber rings are These are "O"-shaped rubber rings, which are respectively the first rubber ring 7, the second rubber ring 8 and the third rubber ring 9.

[0024]In the magnetic fluid shaft sealing device, the non-magnetic metal shell 2 is used to fix the various components of the magnetic fluid shaft sealing device, an...

Embodiment 2

[0045] Sealing pole ring 10: inner diameter=25.6mm. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com